4

2.1. Main Features

2. Understanding Pumps

2.2. Differences Between The Pump Types

Type Stage Nominal Attainable

flow rate Final Pressure

at 50 Hz (Total, without

Gasballast)

UNO 250 A one stage 267 m

3

/h < 5.0 • 10

-2

mbar

DUO 250 A two-stage 267 m

3

/h < 3.0 • 10

-3

mbar

The UNO 250 A is a single stage and the DUO 250 A is a two

stage rotary vane pump.

Special features:

– Pressurised oil lubrication

– Hydraulically controlled high vacuum safety valve

– Optional: Oil filter systems, Condensate separator,

Operational monitoring systems.

Proper Use

– Rotary Vane Vacuum Pumps may only be used to generate

vacuum.

– Installation, start-up, operating and maintenance

instructions must be observed.

– Accessories other than those named in this manual may

not be used without the agreement of Pfeiffer Vacuum.

Special Models

Helium tight model:

– Operating Fluid P3

– Leak rate < 1

• 10

-5

mbar l/s

– Additional radial shaft seal (total of 3) with sealing oil

chamber (oiler)

– Option: Special gas ballast valve for inert gas inlet (N

2

) to

prevent atmospheric air entering the system.

Korrosivgasausführung:

– Operating fluid F5

– Leak rate < 1

• 10

-5

mbar l/s

– Additional radial shaft seal (total of 3) with sealing oil

chamber (oiler)

– Vanes and sight glasses made from special materials.

– Option: Special gas ballast valve for inert gas inlet (N

2

) to

prevent atmospheric air entering the system.

Improper Use

The following are regarded as improper:

– The pumping of corrosive gases (except with corrosive

gas processes version).

– The pumping of gases which are contaminated with

particles, dust and condensate. Avoid condensation and

sublimation; take note to the vapour compatability.

– The pumping of explosive gases.

– Operating the pump in locations where there is an explosi-

on hazard.

– The Rotary Vane Vacuum Pumps may not be used for the

purpose of generating pressure.

– The pumping of liquids.

– Uses not covered above, and, in particular:

– Connection to pumps and units which is not permitted

according to their operating instructions.

– Connection to units which contain touchable and voltage

carrying parts.

Improper use will cause any rights regarding liability and

guarantees to be forfeited.

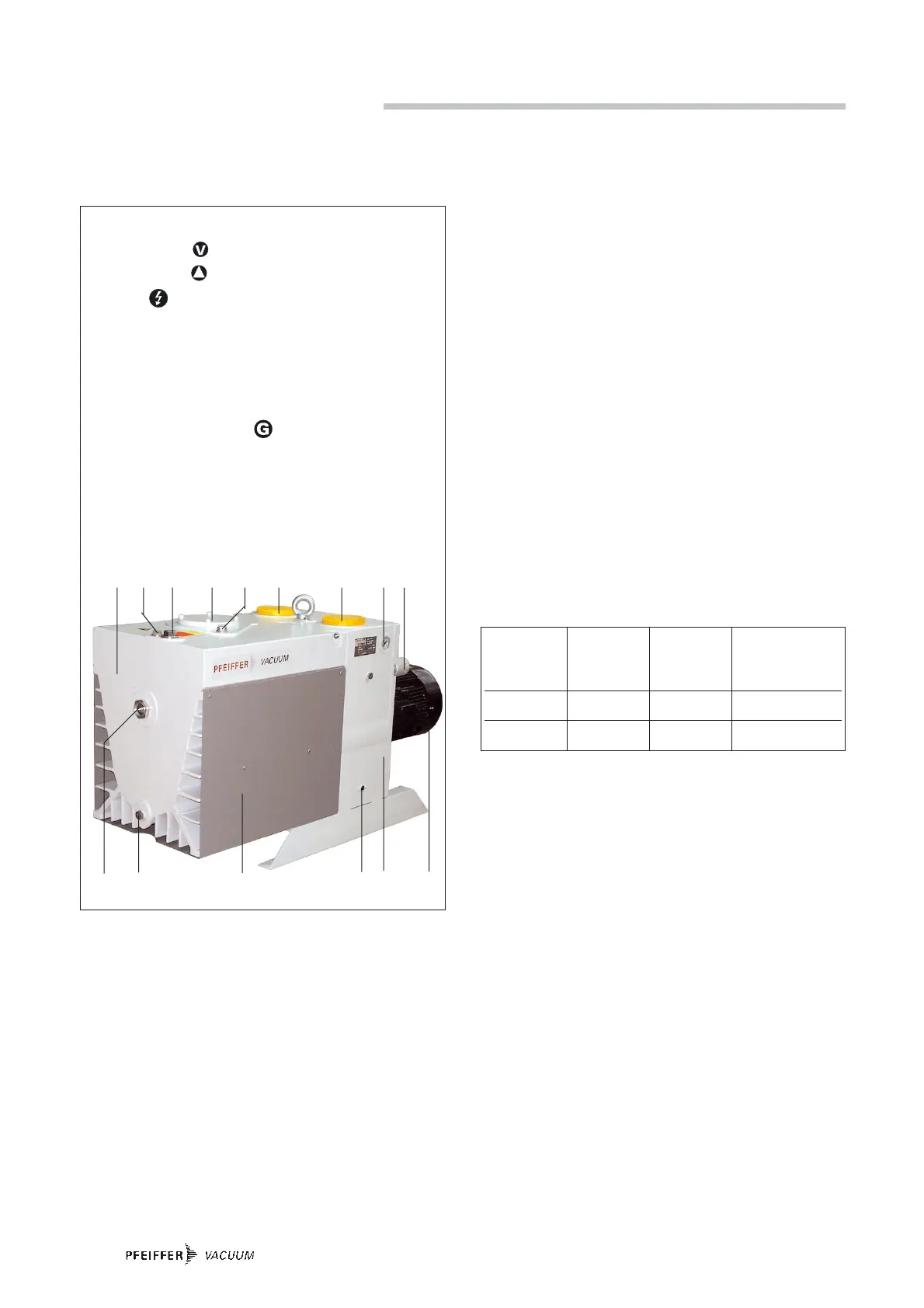

Rotary Vane Vacuum Pumps UNO 250 A, DUO 250 A

1 Vacuum flange,

2 Exhaust flange,

3 Motor,

5 Control voltage connection (for pump monitoring)

15 Casing

18 Baffle Plate

28 Support Stand

42 Operating fluid filler screw

43 Operating medium drain screw

44 Sight glass

45 Gas ballast valve, complete;

46 Screw plug

182 Pressure gauge

183 Cover for filter cleaning

205 Screw plug for adjusting the silencer

15 205 42 183 46 1 2 182 45

44 43 18 5 28 3

Loading...

Loading...