OperatingInstructions&PartsManual

HorizontalRotaryTables

DividingPlates

Pg. 5

Toassemblethedividingplateattachmenttotherotarytable,removehandwheel(Ref.No.46).Bolttherequiredplatetothe

collarusing4screws(Figure3,RefNo.3).Slidethesector(Figure3,Ref.No4)overthewormshaftandeccentricsleeve

(Ref.Nos.31and37)withthesectorscrewexposed.Securesectorbyslidingspringwasher(Figure3,Ref.No.5)againstsector

andintoslotineccentricsleeve.

Slidecrankarm(Figure3,Ref.No.7)overflatsatendofwormshaftandsecurewithspacerandnut(Ref.Nos.50and51).

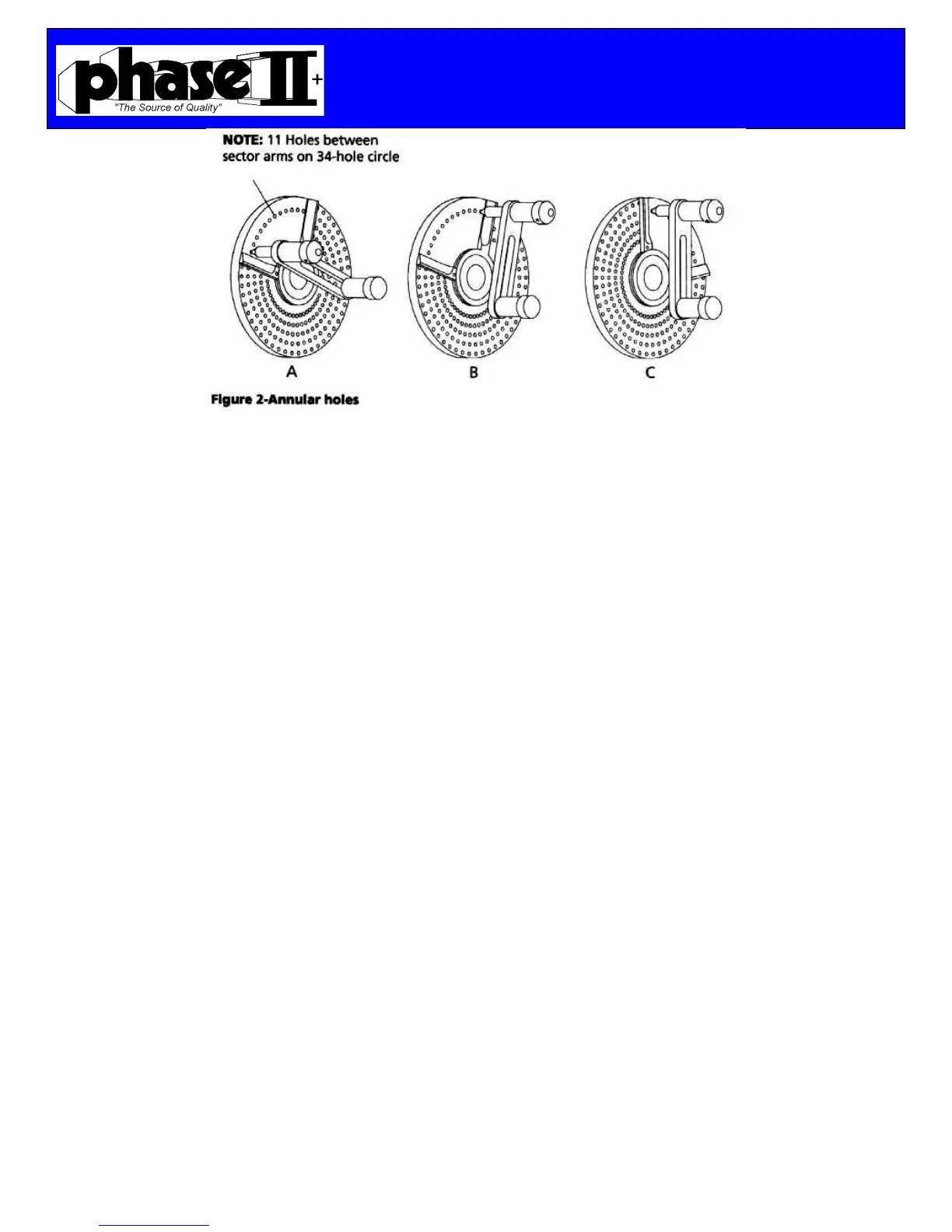

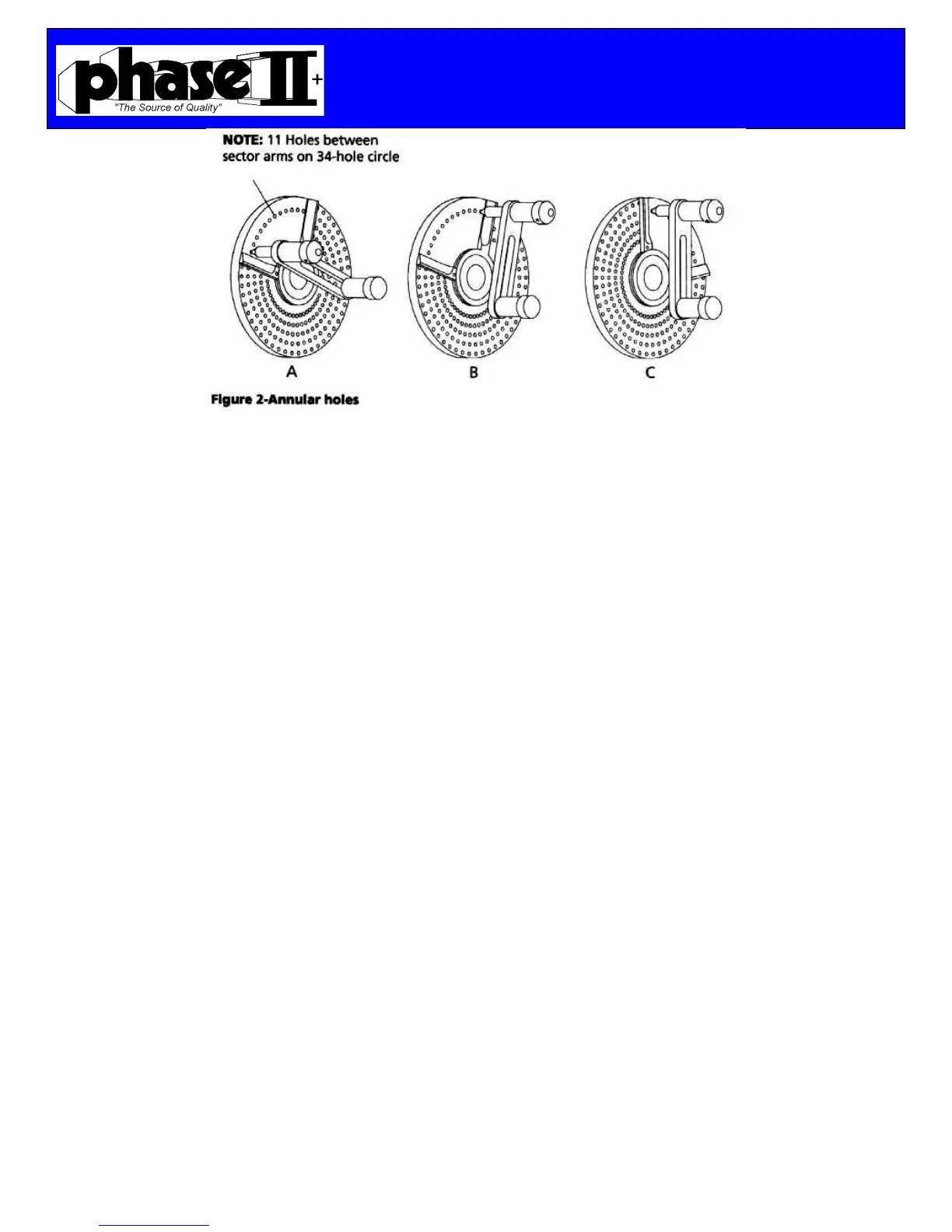

Spreadthesectorarmssothatexactly11holesonthe34holecirclearebetweenthearms(seeFigure2).Tightenthesector

screw.

1. RotatethesectorsothatthesectorarmisagainsttheplungerassemblyasinFigure2A.

2. Rotatetheplungerassemblyclockwise5fullrotationsand10/34ofthearotationbyplacingtheplungerassemblyagainst

thesectorarmasinFigure2B.

3. RotatesectorclockwisesothatfirstarmisagainstplungerassemblyasinFigure2C.

Repeatsteps1,2and3foreachdivision.Thedividingchart(Page4)showsthatfor19divisionstheplatewith38holesis

requiredandeachdivisionneeds4fullrotationplus28/38ofarotation.Thedividingchartshowsthatfor53divisions,each

divisionrequires1and37/53rotations,etc.Forevendivisionsof90(2,3,4,5,6,9,10,15,18,30and45)simplyrotatethe

crankarmrequirednumberoffullturnsusingthesameholeonanyplate.

Maintenance

RefertoFigure4thru8.

WormShaftAdjustment

Toadjustforwearinthewormshaft,thelocknut(Ref.No.35)mustbeadjusted.

Removehandwheel(RefNo.46)andspacer(RefNo.36)Tightenlocknutuntilplayisremovedfromengagedwormshaftand

clampingsurface.Donotover‐tightenlocknut.Replacespacerandhandwheel.

EccentricSleevelimitscrewadjustment

Thethreadedpin(RefNo29)regulatestherotationateccentricsleeve.Ifthewormshaftdoesnotengagetableproperlywhen

verniercollarisrotatedcounterclockwise,thenunscrewsetscrew(RefNo,28)andadjustthethreadedpinuntilproper

engagementisachieved.

Note:Formodel221‐308setscrew(RefNo.28)andthreadedpin(RefNo.29)islocatedinlowerrightcornerofthebottomof

thebasecasting(RefNo.1)

Loading...

Loading...