HUDSON 9

68

68

4.6 White color adjustment

There are three factory preset white color 9300K, 6500K, sRGB Align by FGA function.

Apply full gray64 pattern, with brightness in 100 % position and the contrast control at 50 % position.

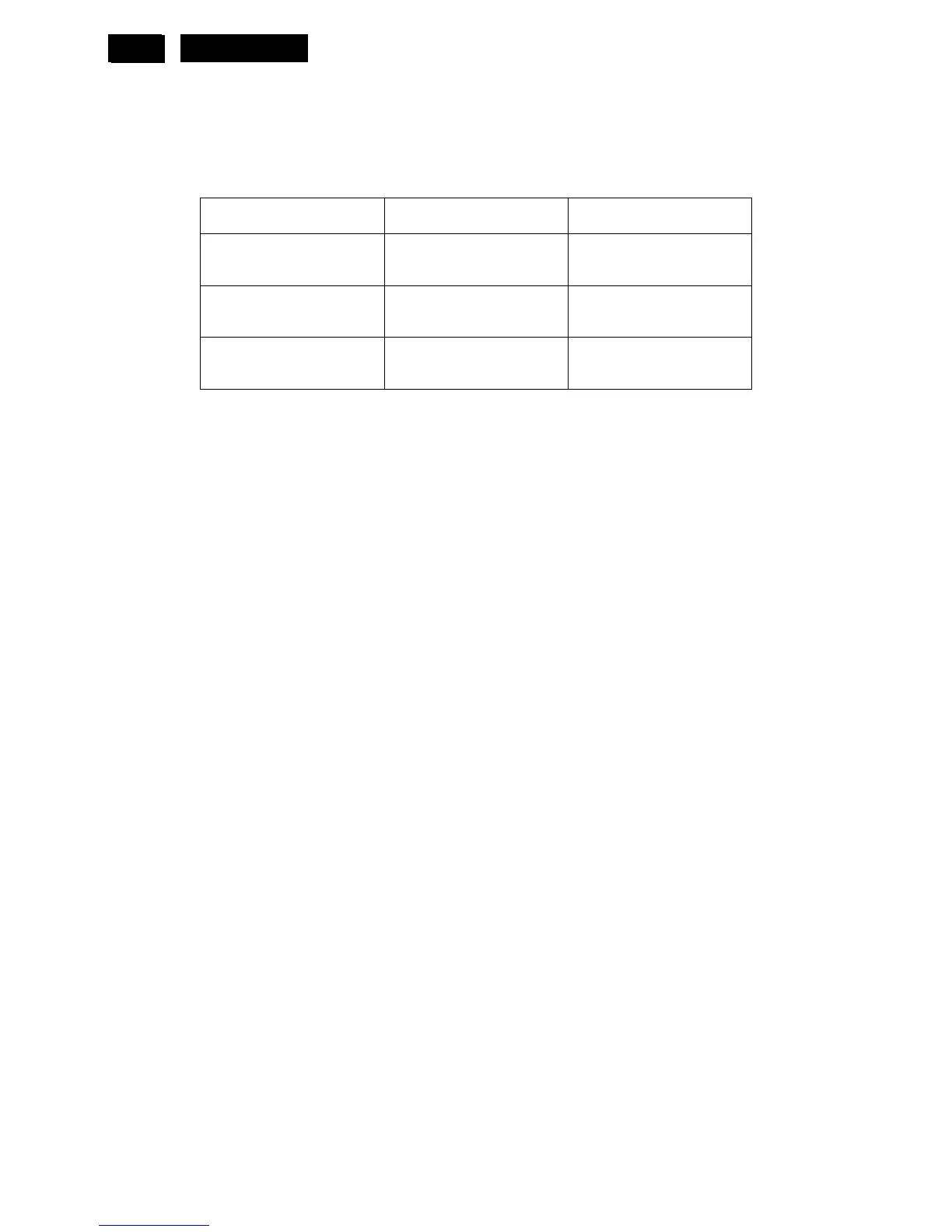

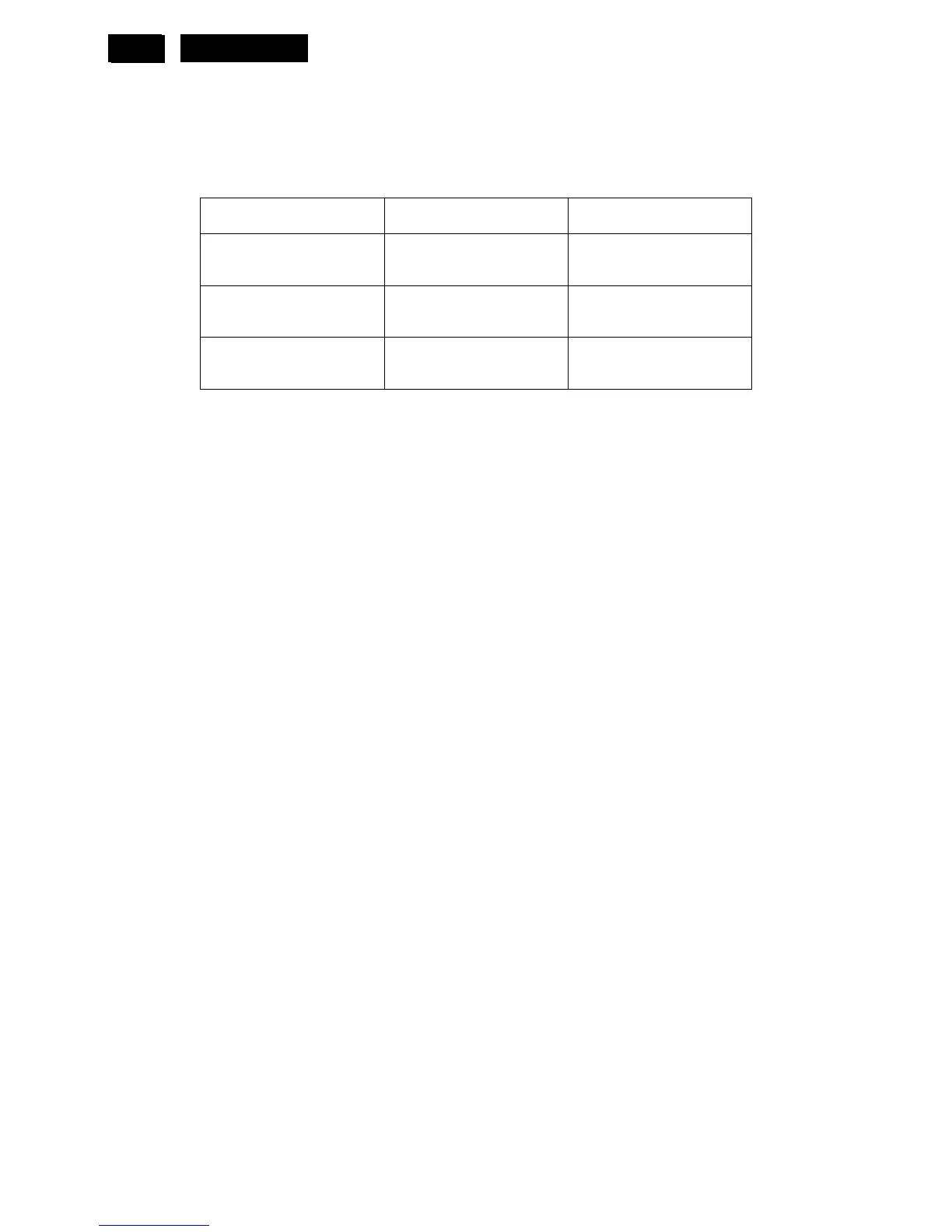

The 1931 CIE Chromaticity (color triangle) diagram (x, y) coordinate for the screen center should be:

Product specification

CIE coordinates (x,y)

9300K

x = 0.283 ± 0.015

y = 0.297 ± 0.015

6500K/sRGB

x = 0.313 ± 0.015

y = 0.329 ± 0.015

sRGB

x = 0.313 ± 0.015

y = 0.329 ± 0.015

5. Mechanical characteristics

5.1 Cosmetic - Philips ID

5.2 Mechanical data files - ProE files required

5.3 Location of Philips logo - Per Philips make-up sheet

5.4 Gap between panel and front bezel < 0.8 mm (typ)

5.5 Location of Control icons - Per Philips Graphic sheet

5.6 Color for resin/paint - Per Philips make-up sheet

5.7 Resins

z ROHS required

z WEEE required.

z Resin type/selection refers to Project Book Section 7.2 Plastic material.

5.8 If paint is used

z ROHS required

z WEEE require

z If new painting type needs to implement, refer to UN-D 1235.

5.9 Plastic mold tooling

z Tooling to be designed to minimize cosmetic defects induced by molding process (sink, blush, weld lines,

gate marks, ejector marks, etc.). Refer to “TYV61-90007”.

z Painting to cover up cosmetic defects due to molding is strongly discouraged.

z China ROHS mark requested.

5.10 Plastics flammability

z All Plastics to be Flame Retardant UL 94-HB.

z Base/Rear to be Flame Retardant UL 94-HB.

z All major plastic parts (bezel, back cover, base) need to be molded from same resin. Plastic resin type

selection should be referred to “TY R83-2-9002-1”.

Loading...

Loading...