(4)

High

Frequency

Response

Check and

Adjustment

Gautions:

a

Be

sure

to

check

the

frequency response

after the

head

assembly

is replaced.

o

lÍ

the frequency response

does

not fall within

the

limits,

perform

the

Íollowing

adjustment.

Frequency

Response

Check

1. Play

back 250H2,

-20d8

and

12.5kH2,

-20dB

of the

ACC Test Tape

(SBC420)

forward,

and

verify

that

the leveldifference

between the two bands

is within

0

t 1dB.

2.

Reverse

the direction of tape transport

and

perform

the same check.

Adjustment Procedure

1. While

playing

back

250H2, -20d8

oÍ ACC

Test Tape

(SBC420)

forward, measure

the

LINE OUT

levels

on both channels. Use these

levels

as standards.

2. Play

back

12.5kH2,

-20d8 of the same test tape

foruvard,

and

adjust R151

(L

ch) and

R152

(R

ch) until

the

LINE

OUT levels are identicalto the standard

levels

obtained above.

Adjustment Target:

0

í).5d8

o

3.

Reverse

the direction of tape transport and

perform

the same

check.

Gheck

Target:

0

t1

.sdB

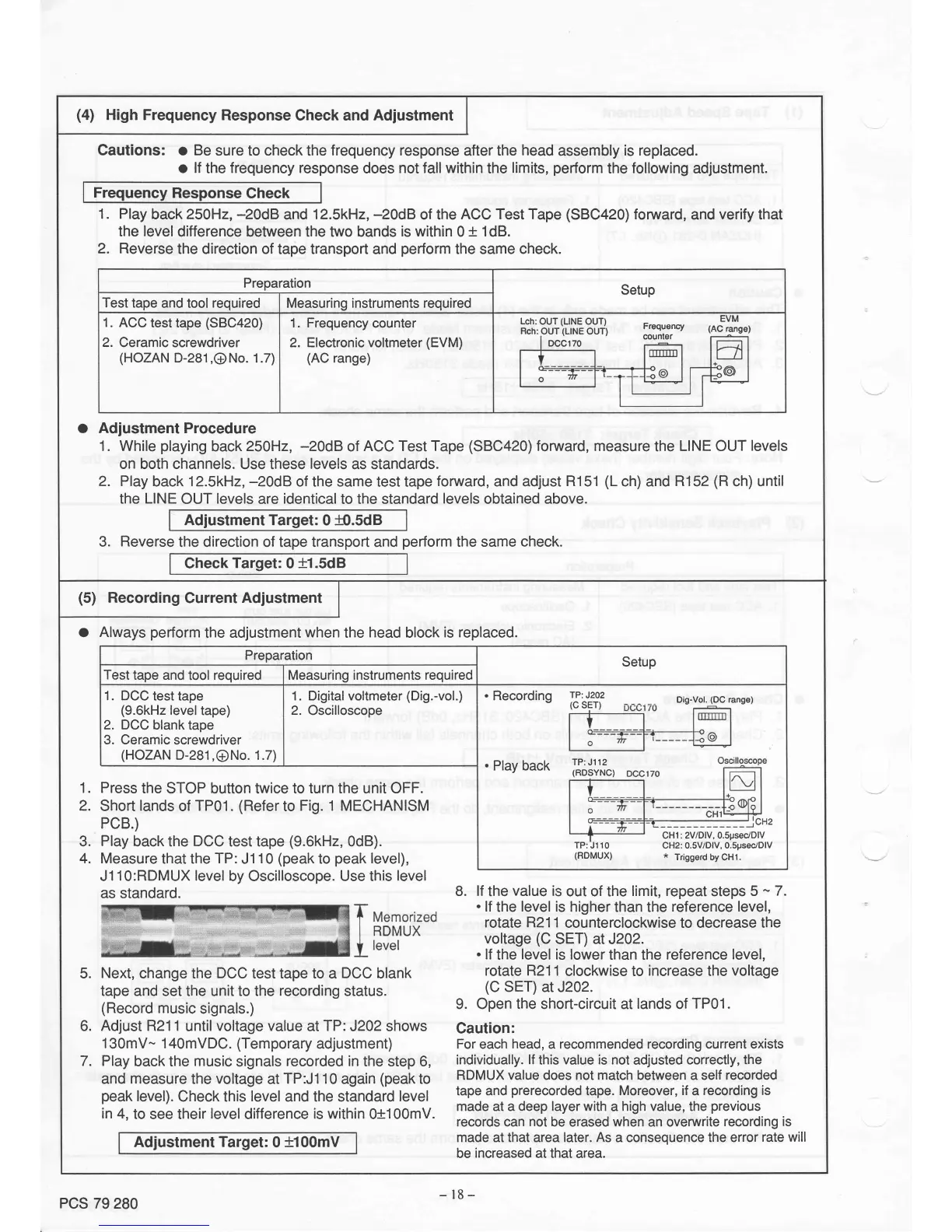

Preparation

Setup

Test

tape

and tool

required

Measuring instruments required

1.

ACC

test

tape

(SBC420)

Ceramic

screwdriver

(HOZAN

D-281

,G)

No. 1.7)

2.

1. Frequency

counter

2. Electronic voltmeter

(EVM)

(AC

range)

Lch:

OUT

(LINE

OUT)

Frequency

counter

Rch:

OUT

(LINE

OUT)

DCCl70

(5)

Recording

Current

Adiustment

o Always

perform

the

adjustment

when

the

head

block

is replaced.

1.

2.

3.

4.

J11O:RDMUX

level

by

Oscilloscope.

Use this

level

as standard.

5.

Next,

change the

DCC

test tape to

a

DCC

blank

tape and set the unit to the

recording

status.

(Record

music

signals.)

6.

Adjust R21 1

until

voltage

value

at

TP:

J202 shows

1

30mV^.

1

4}mVDC.

(Temporary

adjustment)

7. Play

back the

music

signals

recorded in

the

step

6,

and

measure

the

voltage

at

TP:J1 10

again

(peak

to

peak

level).

Check this

level

and the standard

level

in 4,

to see

their

level

difference

is within

0+1 00mV.

Adjustment Target:

0

t100mV

B.

ff

the

value

is

out of the

limit, repeat

steps

5

-

7.

.

lf

the

level

is higher

than the

reference level,

rotate R211

counterclockwise to decrease

the

voftage

(C

SET) at J202.

.

lf

the

level

is lower

than the

reference

level,

rotate R211

clockwise

to

increase

the

voltage

(C

SET)

aï J202.

9. Open

the

short-circuit at

lands

of

TP01.

Caution:

For

each

head,

a

recommended recording current exists

individually.

lf

this

value is

not

adjusted

correctly,

the

RDMUX

value

does not

match

between

a self

recorded

tape and

prerecorded

tape. Moreover,

if

a

recording

is

made at a

deep layer with

a

high value, the

previous

records can

not

be

erased

when

an overwrite

recording

is

made at that area later.

As

a consequence the error

rate will

be

increased

at that

area.

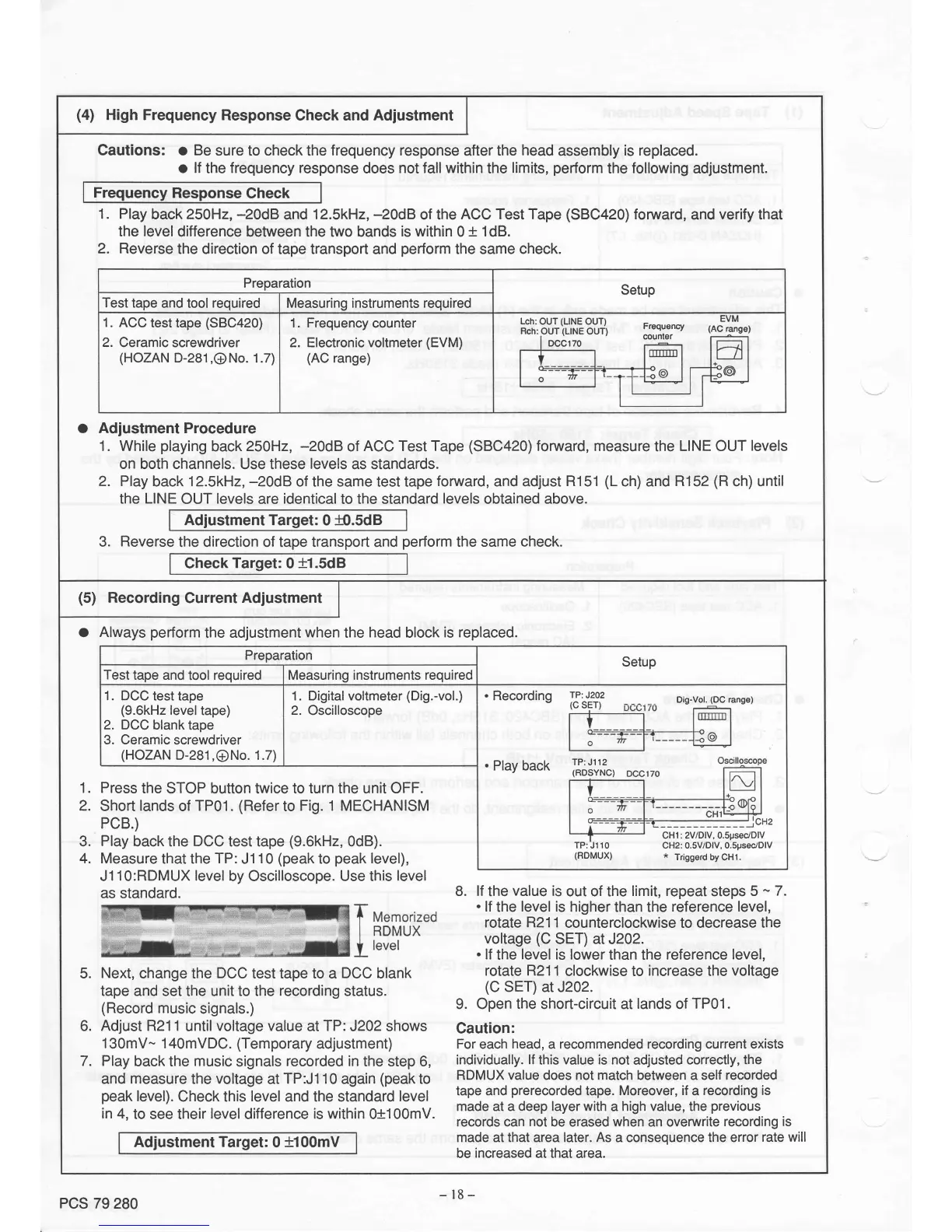

Preparation

Setup

Test

tape and

tool

required Measuring instruments required

1.

DCC

test

tape

(9.6kHz

level

tape)

2. DCC

blank

tape

3. Ceramic

screwdriver

(HOZAN

D-281

,ONo.

1.7)

1.

2.

Digital voltmeter

(Dig.-vol.)

Oscilloscope

.

Recording

TP:

J2o2

Dis-vot.

(DC

range)

.

Play back

TP:

J202

(c

sET)

TP: Jl12

(RDSYNC)

TP:

J110

(RDMUX)

CHl : 2V

lDlV,

O.Spsec/DlV

CH2

:

0.5V/DlV,

0.SpsedDlV

*

Triggerd

by CHl.

Press

the

STOP button twice to turn

the

unit OFF.

Short

lands

of

TP01.

(Refer

to

Fig. 1

MECHANISM

PCB.)

Play

back

the

DCC

test tape

(9.6kH2,

OdB).

Measure

that the

TP:

J110

(peak

to

peak

level),

PCS

79

280

- l8

-

Loading...

Loading...