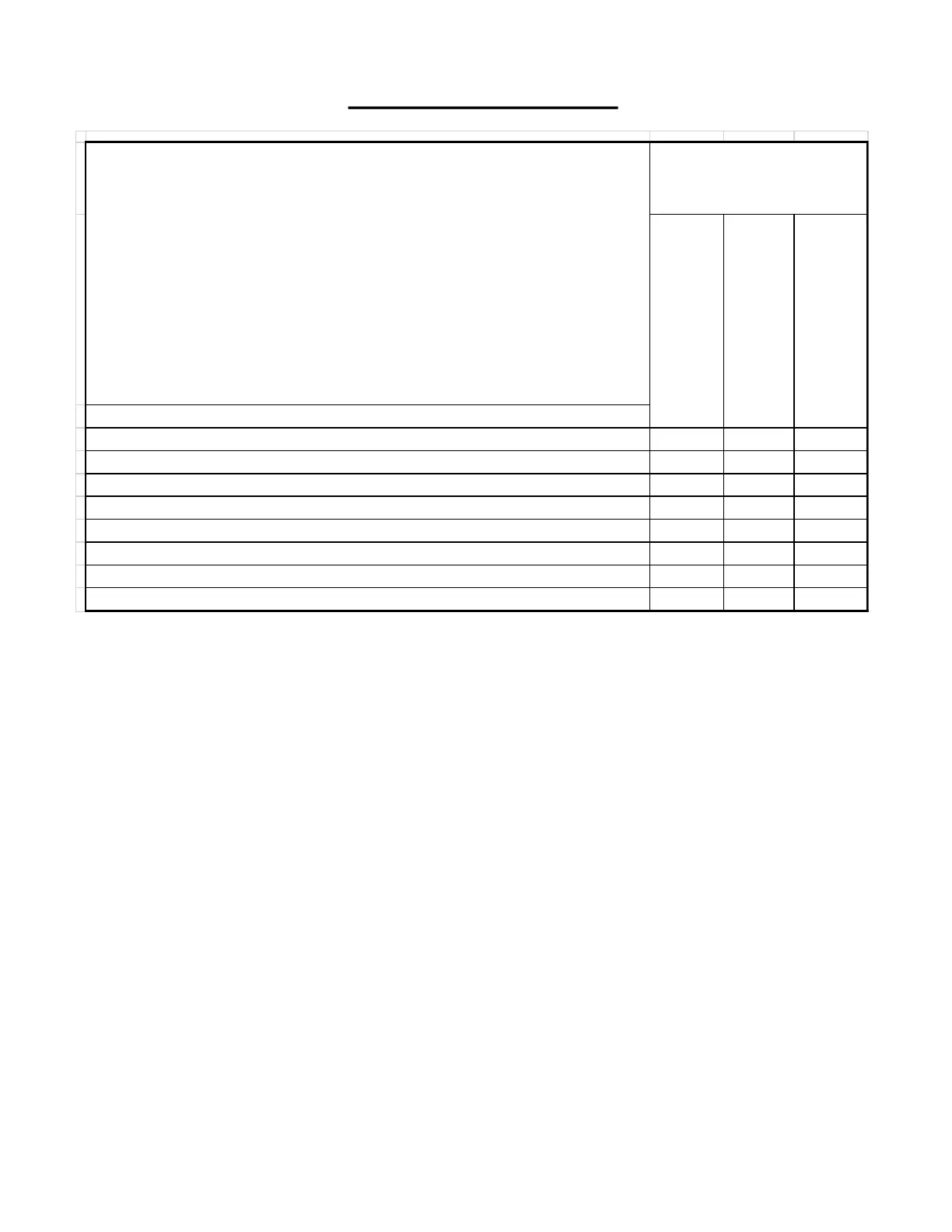

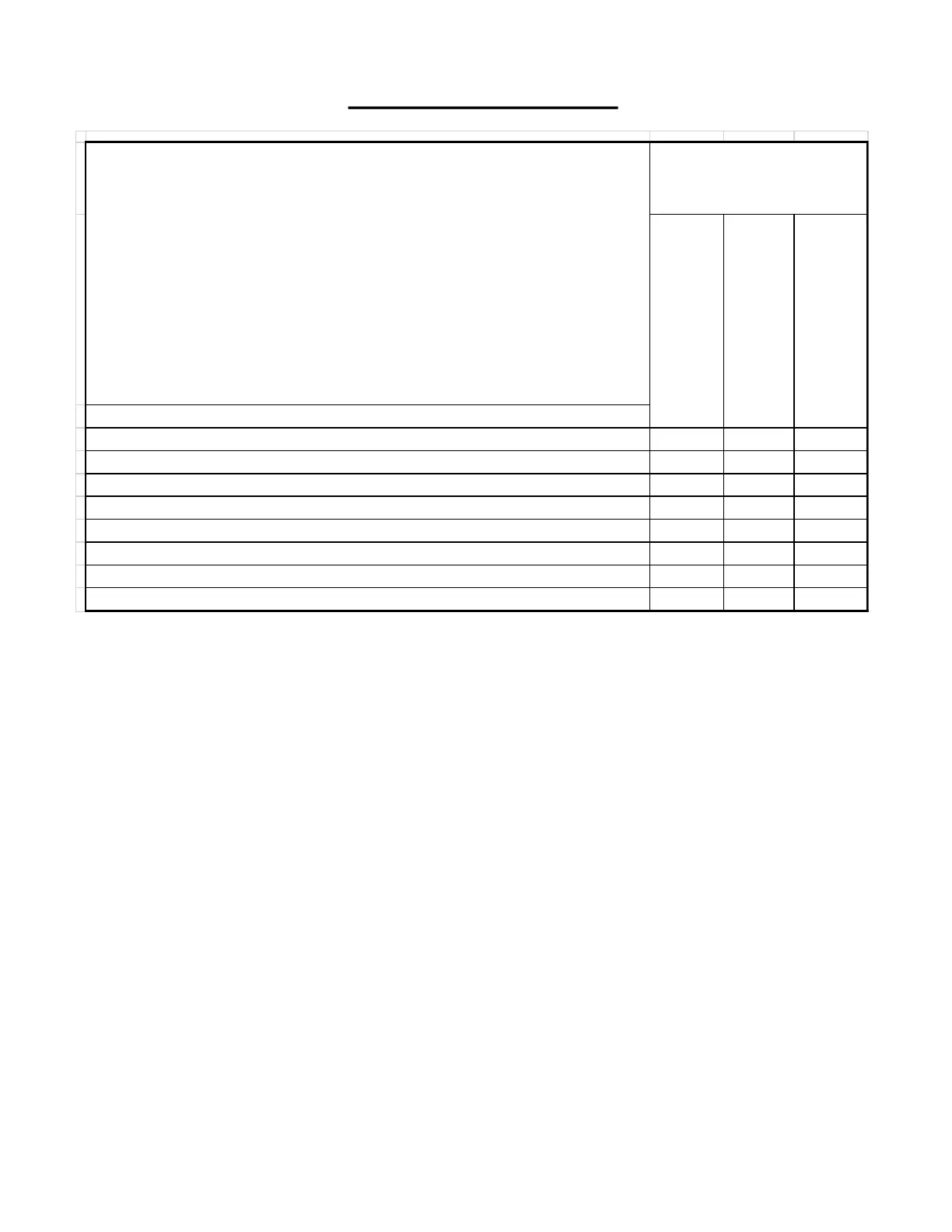

Parts Requiring Maintenace

Cabinet Fan Intake Filter Daily

Table Surface Areas Daily

Backstops and Fences for part locating Daily

All sensors and Proximity Switches Daily

X and Y linear slide bearings and Rails (Carraige and Drill) Daily 80 Hrs

X Axis rack and pinion gears (Carriage) Daily 80 Hrs

Z Axis linear slide bearings and rails (Opiton) Daily 80 Hrs

Z Axis ball screws (Option) Daily 80 Hrs

MAINTENANCE KEY:

Daily: Maintenance listed below should be performed as often as needed

during operation on a daily basis.

Hours (Hrs.): Maintenance listed below should be performed each time the

machine has been in operationfor that length of time.

Example: Clean rails and grease each bearing with 1 pump of grease at zerk

fitting every 80 hours of operation.

Clean

dust and

chip

buildup

Clean

grease

and

grime.

Apply

spray-on

dry lube.

Clean

grease

and

grime.

Give 1

pump

grease at

zerk

RECOMMENDED GREASE TYPE:

MOBIL TH SCHyPM NGLI Grade 1/5 or equivalent HIGH PERFORMANCE LITHIUM BASED GREASE.

RECOMMENDED SPRAY-ON DRY LUBRICANT:

SPRAYON S00708 T.F.E. DRY LUBE, or GRAPHITE BASE LUBRICANT

AIR SYSTEM LUBRICATOR:

Use a high grade, light hydraulic oil in the air lubricator bowl. Set the drip rate for approximately one drop every 100 cycles.

(completely close valve and open 1/8 to 1/4 turn)

BARE STEEL PARTS:

Spray on Boeshield T-9 Waterproof Lubricant and wipe evenly with a clean rag to coat Clamp Bar once a month or as need-

ed to prevent rust. (Pillar Machine part # S4410)

NOTE:

All support bearings on Ball Screws are sealed bearings and do not require addional lubricaon.

Loading...

Loading...