PIPER

SENECA II

SERVICE MANUAL

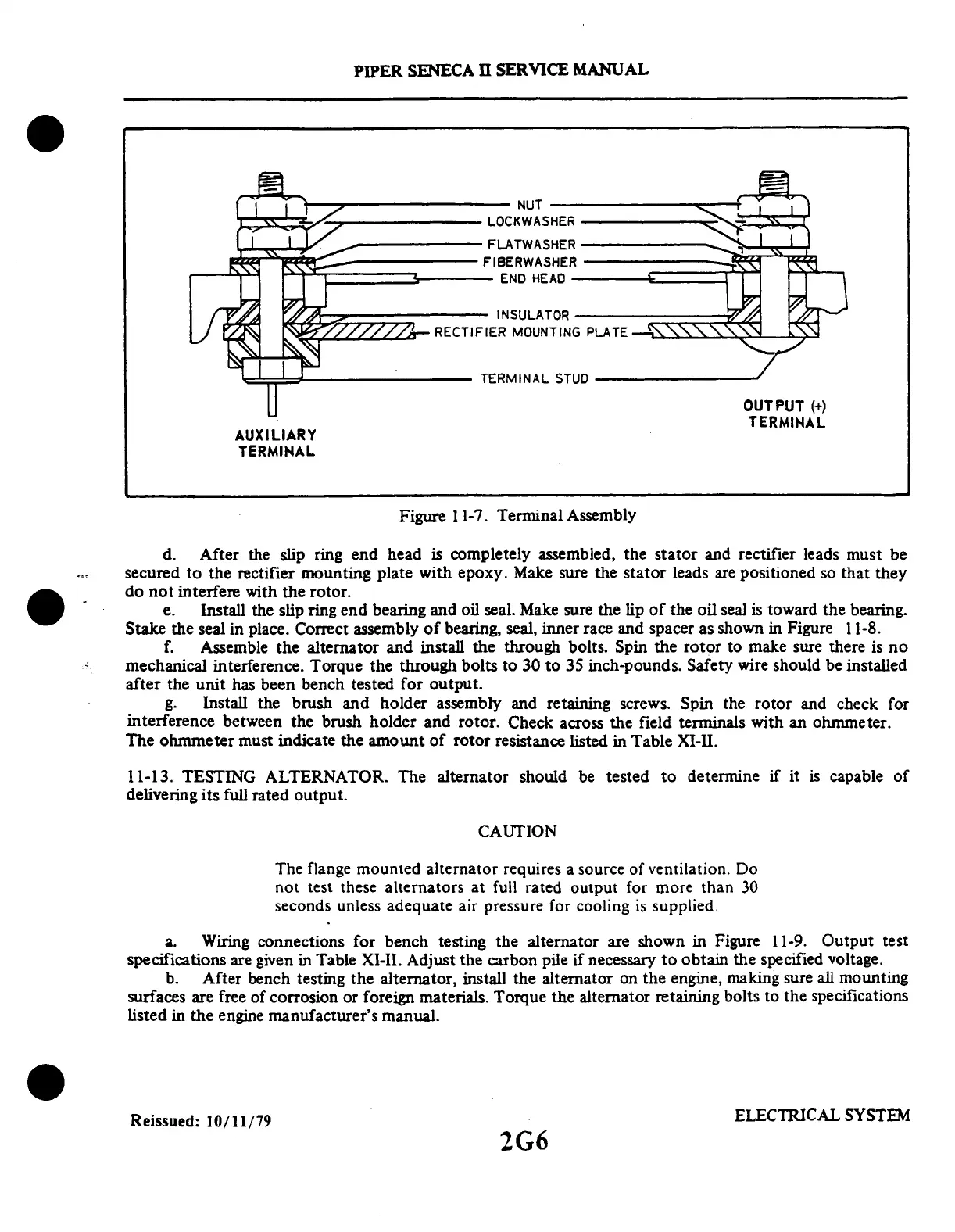

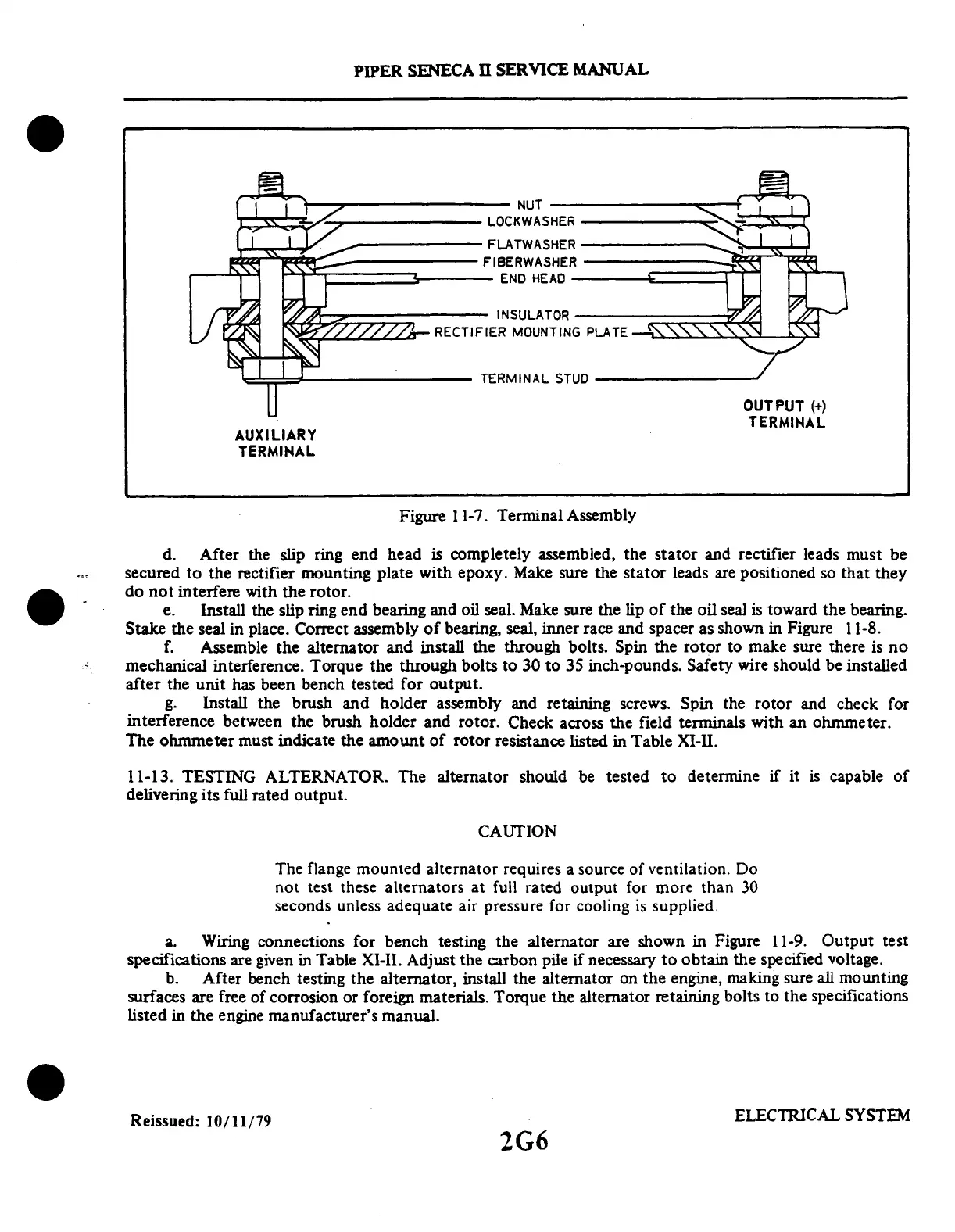

NUT

LOCKWASHER

FLATWASHER

FIBERWASHER

INSULATOR

RECTIFIER MOUNTING PLATE

TERMINAL STUD

OUTPUT (+)

TERMINAL

AUXILIARY

TERMINAL

Figure 11-7.

Terminal

Assembly

d.

After the slip ring end head is completely

assembled, the stator and rectifier leads

must be

secured to the rectifier mounting

plate with epoxy. Make sure the stator leads

are positioned so that they

do not interfere with the rotor.

e. Install the slip ring end bearing and oil seal. Make sure the lip of the oil seal is toward the bearing.

Stake the

seal in place. Correct

assembly of bearing,

seal, inner race and

spacer as shown in Figure

11-8.

f. Assemble the alternator and install the through bolts. Spin the rotor to make sure there is no

mechanical interference. Torque the through bolts to 30 to 35 inch-pounds. Safety wire should be installed

after the unit has been bench tested for output.

g. Install the brush and holder assembly and retaining screws. Spin the rotor and check for

interference

between the

brush holder

and rotor. Check

across the

field terminals

with an ohmmeter.

The ohmmeter must indicate the

amount of rotor resistance listed

in Table XI-II.

11-13. TESTING ALTERNATOR. The alternator should be tested to determine if it is capable of

delivering

its full rated

output.

CAUTION

The flange mounted alternator requires a source of ventilation. Do

not test these alternators at full rated output for more than 30

seconds unless adequate air pressure for cooling is supplied.

a. Wiring connections for

bench testing the alternator are shown

in Figure 11-9. Output test

specifications

are given in Table XI-II. Adjust the carbon

pile if necessary to obtain the specified voltage.

b. After

bench testing the

alternator, install the

alternator on the engine,

making sure all

mounting

surfaces are free of corrosion or foreign materials.

Torque the alternator retaining bolts

to the specifications

listed in the engine manufacturer's manual.

Reissued: 10/11/79

ELECTRICAL SYSTEM

2G6

Loading...

Loading...