TB-SRTG: Gas Floor Model Rethermalizer INSTALLATION

L20-376, rev. 1 (08/18) 11

OFF

ON

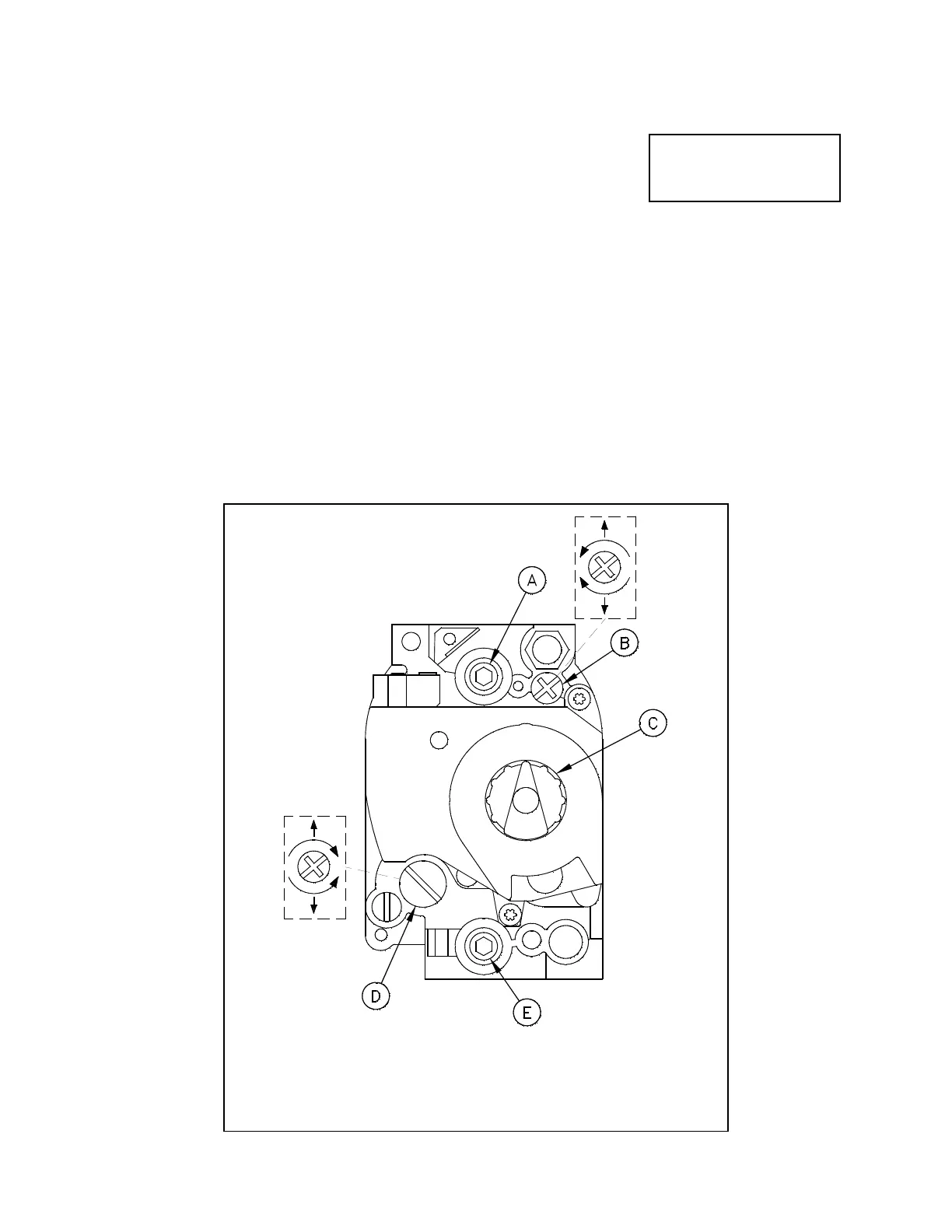

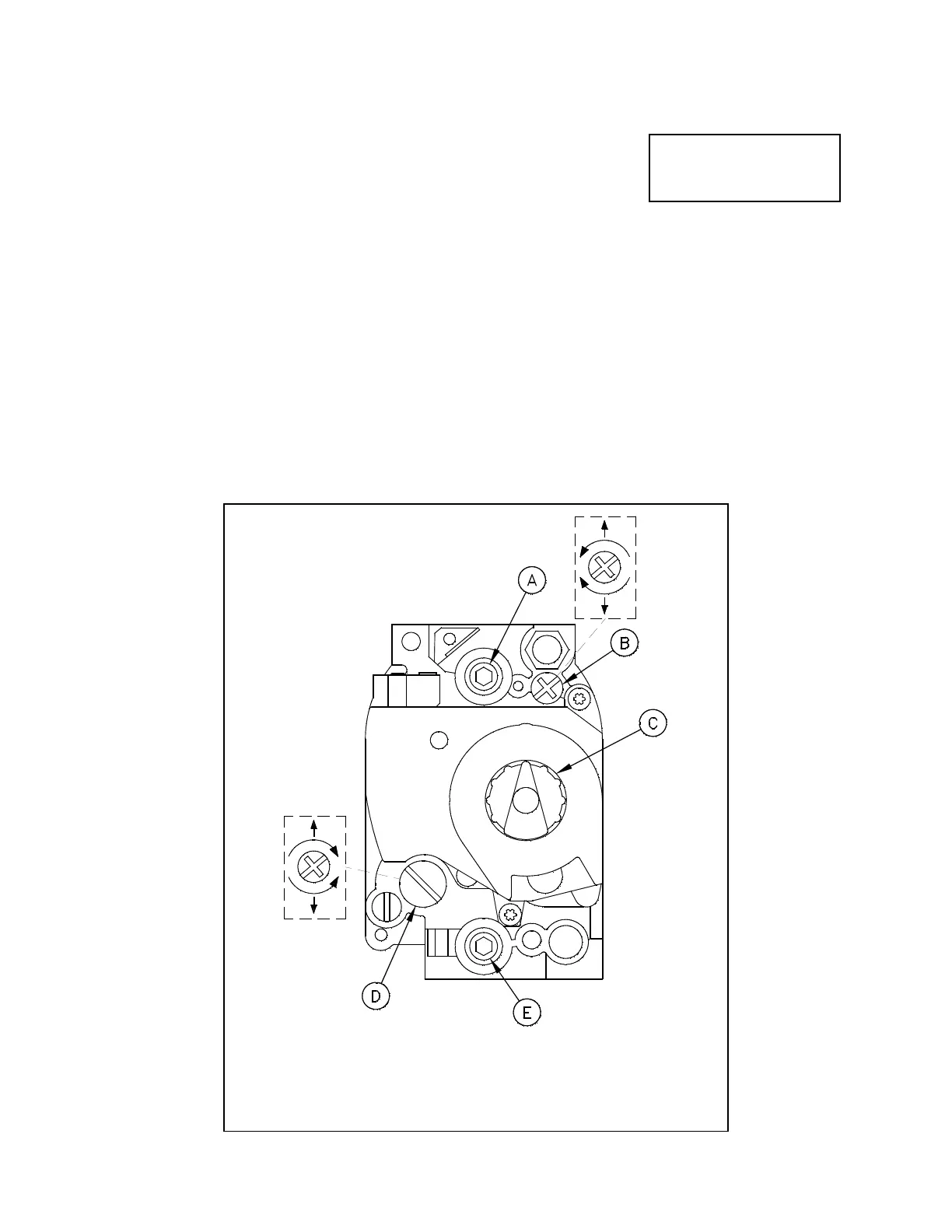

A) Burner Pressure Tap

B) Pilot Adjustment Screw Cap

C) ON/OFF Knob

D) Burner Pressure Adjustment Screw Cap

E) Inlet Pressure Tap

Note: This procedure

requires the use of a

DC microammeter.

1.9.3. PILOT FLAME ADJUSTMENT

Perform this procedure with the pilot lit.

1. Connect the DC microammeter between the flame sensor

terminal and the flame sensor lead. Observe proper polarity: if

the meter needle goes below 0, reverse the leads. The current

reading must be 1.0 A or greater, (0.15 A or greater for CE units).

2. Adjust the current reading to the required level by adjusting the pilot flame. Remove the pilot

adjustment screw cap screw to expose the pilot adjustment screw. Turning the pilot

adjustment screw clockwise will decrease the size of the pilot flame and flame sense current.

Turning the pilot adjustment screw counterclockwise will increase the pilot flame size and the

flame sense current.

3. Rotate the screw in the direction needed to achieve a reading of 1.0 A or greater, (0.15 A

or greater for CE units).

Note: Allow 3 to 5 minutes between flame adjustments to allow the reading to stabilize.

4. Once the pilot flame has been adjusted properly, replace the pilot adjustment screw cap

screw and remove the microammeter.

Loading...

Loading...