8 Fusion Operating instructions SG 160

30

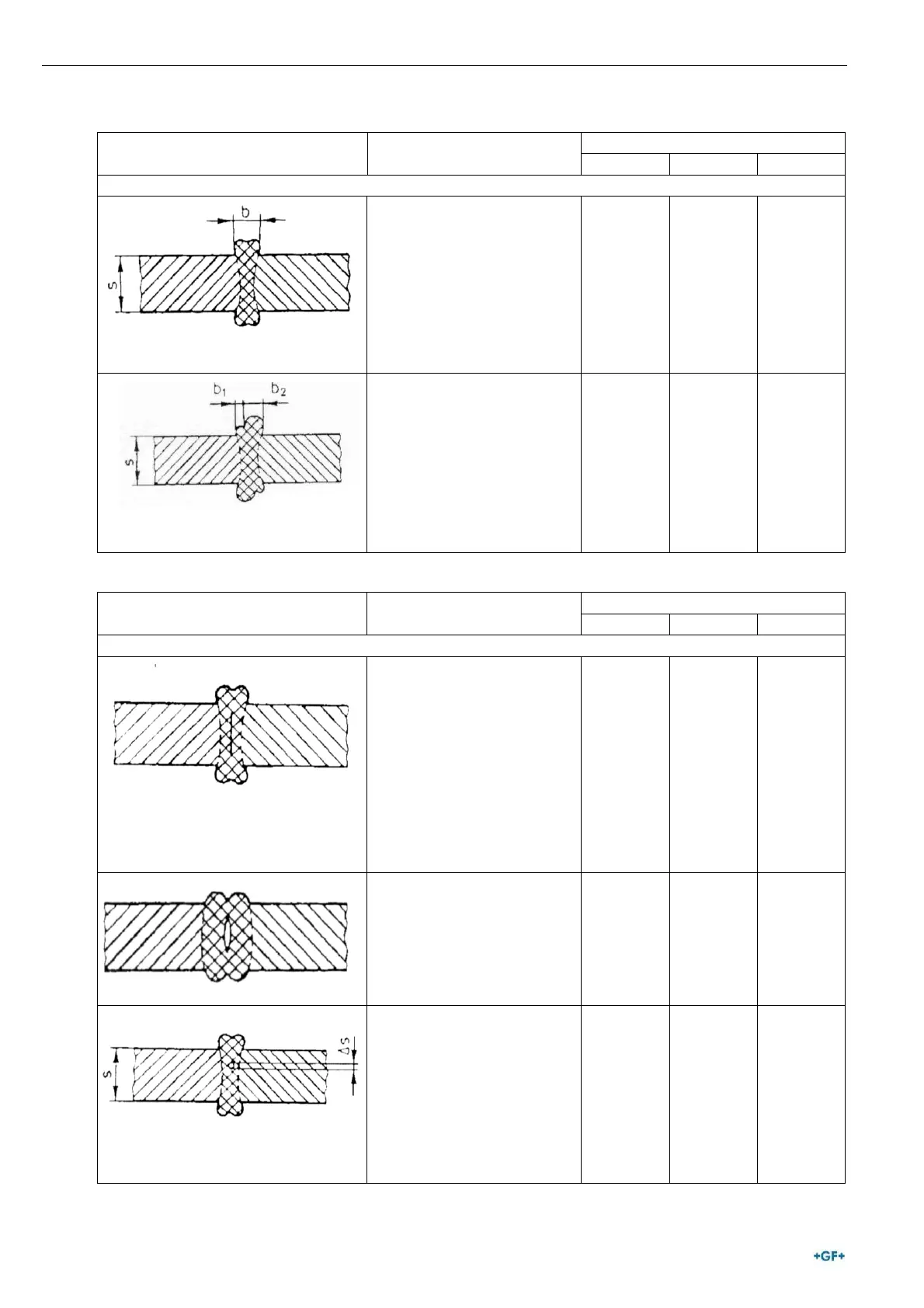

Feature Description Evaluation group

External state of joint

Welding flash too wide or too

narrow over part or all of weld

length, caused by, for example:

• incorrect warming-up

time

• incorrect heating-

element temperature

• incorrect joint pressure

See pg.14

DVS 2202-1

guidelines

See pg.14

DVS 2202-1

guidelines

See pg.14

DVS 2202-1

guidelines

Non angular joint plane, leading

to variations in form of welding

flash over part or all of weld

length, caused by, for example:

• edge preparation faults

• incorrect welding unit

Permissible

if

b1≥ 0,7 x b2

Permissible

if

b1≥ 0,6 x b2

Permissible

if

b1≥ 0,5 x b2

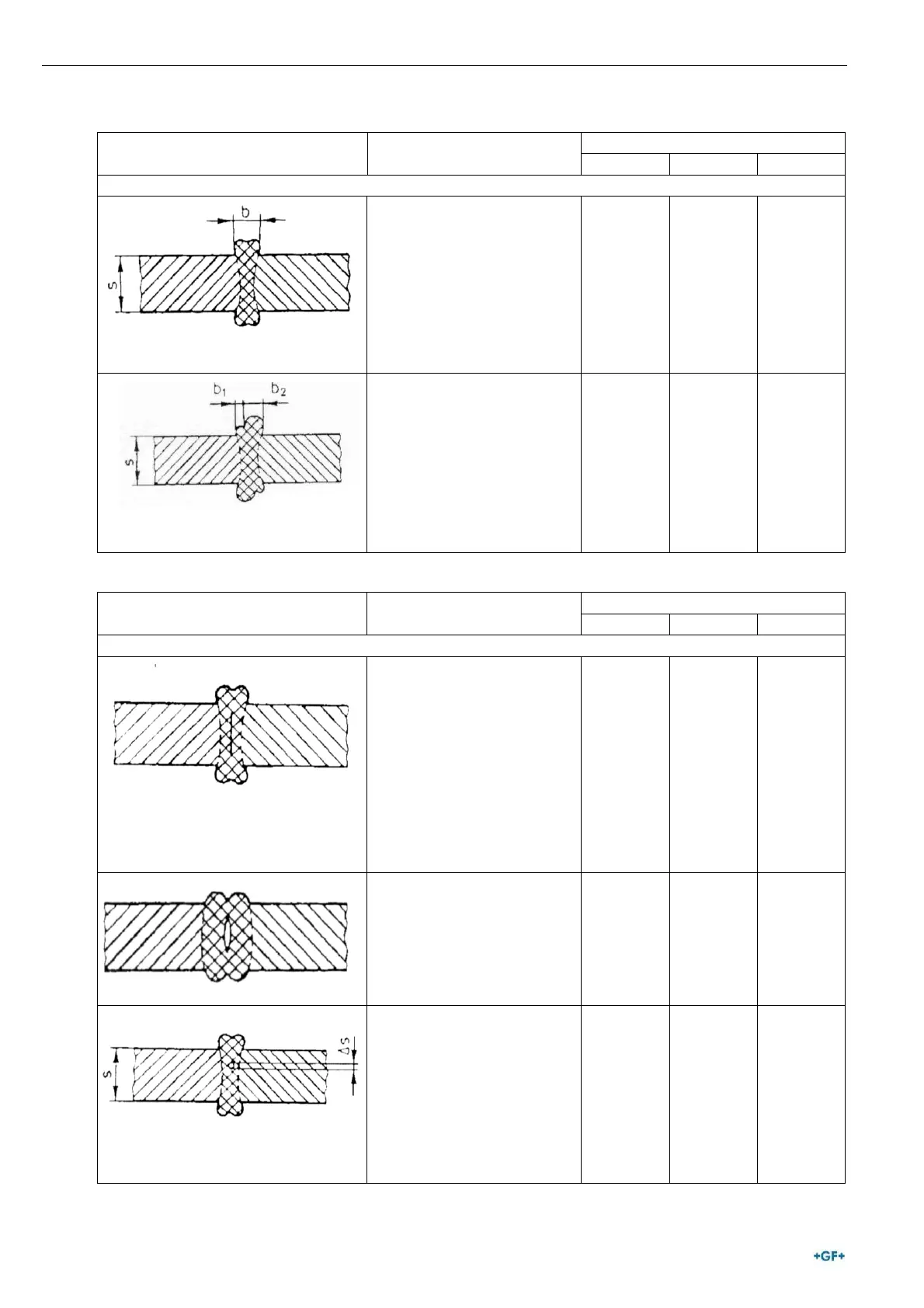

Feature Description Evaluation group

Internal state of joint

No fusion or incomplete fusion

on joint faces, over part or the

whole of weld cross-section

caused by, for example:

• contaminated joint faces

• oxidized joint faces

• excessive reversal time

• heating element

temperature too low

• heating element

temperature too high

Not

Permissible

Not

Permissible

Not

Permissible

Hollow space in joint planes

caused by, for example:

• Insufficient joint pressure

• Insufficient cooling time

Not

Permissible

Not

Permissible

Not

Permissible

Isolated, numerously dispersed

or locally concentrated pores or

inclusions caused by, for

example:

• Vapour formation during

welding

• Contaminated heating

element

Permissible

if

∆s ≤ 0.05 x s

Permissible

if

∆s ≤ 0.10 x s

Permissible

if

∆s ≤ 0.15 x s

Loading...

Loading...