Operating instructions SG 160 8 Fusion

29

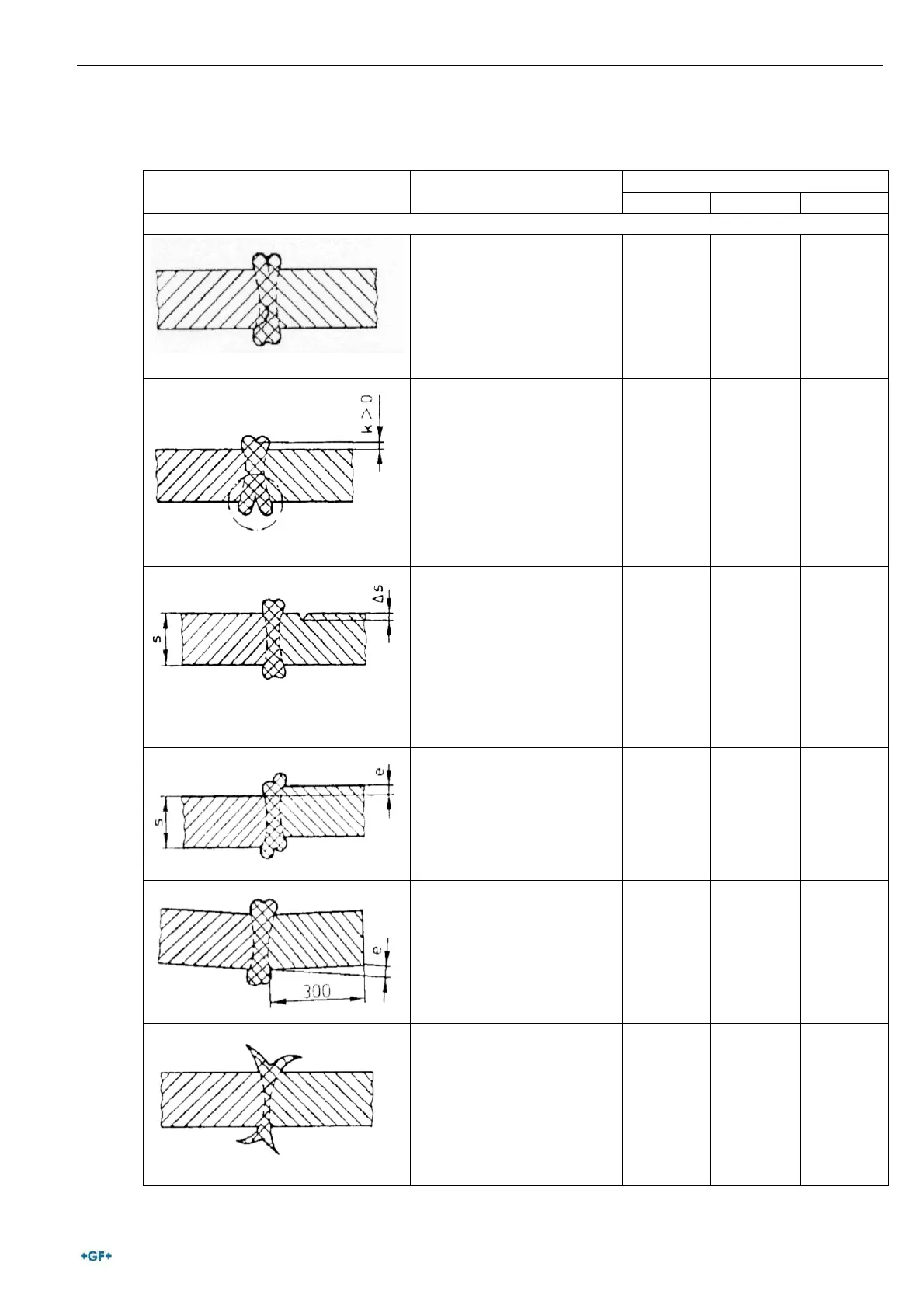

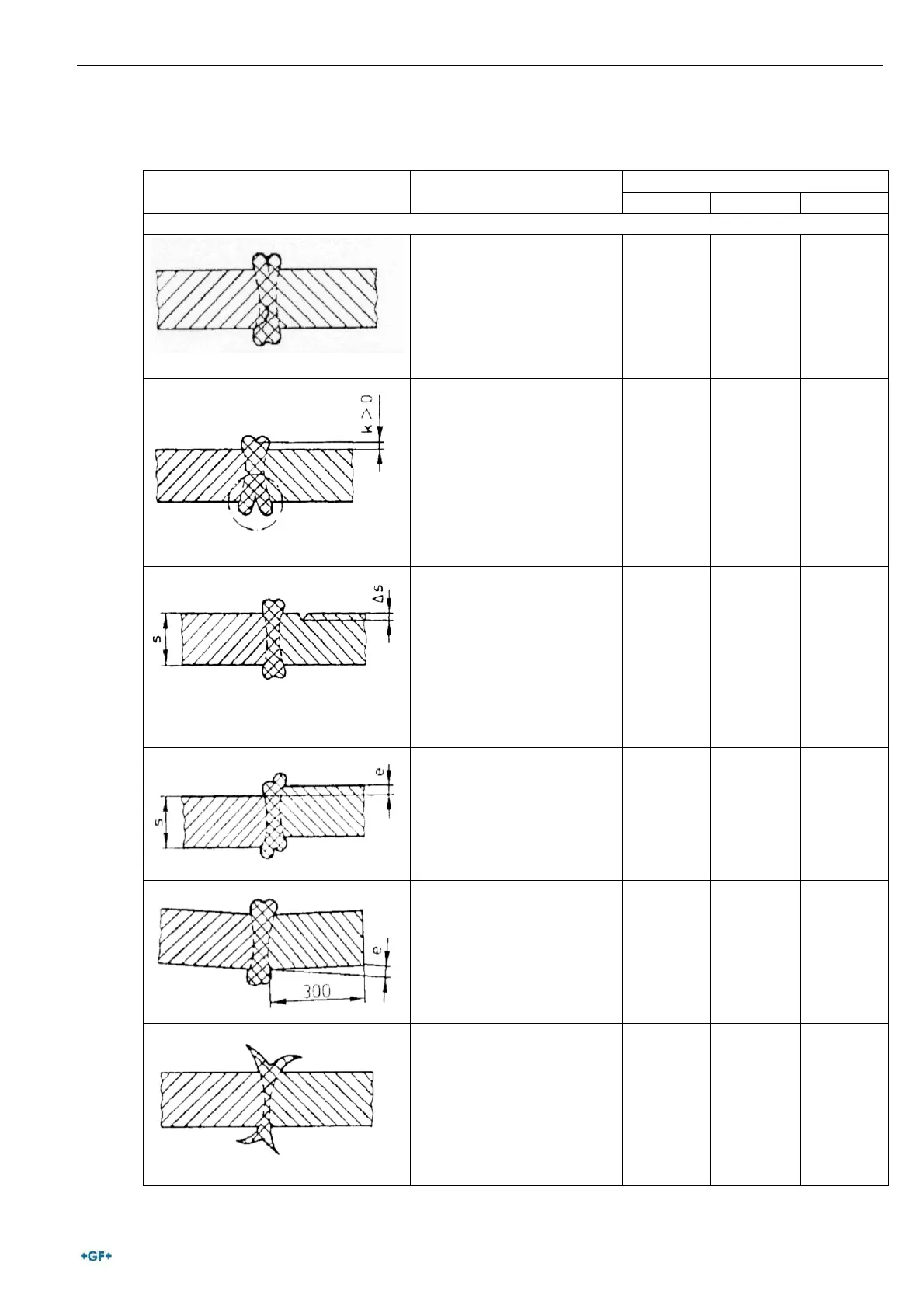

8.1.5 Failure analysis

Feature Description Evaluation group

External state of joint

Cracks running length-wise or

cross-wise to weld. They may

be located:

• In the weld

• In base material

• In heat affected zone

Not

Permissible

Not

Permissible

Not

Permissible

Continuous or local notches

length-wise to weld with notch

root in base material, caused

by, for example: :

• Insufficient jointing

pressure

• Warming-up time too

short

• Cooling time too short

Not

Permissible

Not

Permissible

Not

Permissible

Notches in edge of base

material, length-wise or cross-

wise to weld, caused by, for

example:

• Clamping tools

• Incorrect transport

• Fault in edge preparation

Locally

permissible

if ending

flat and

∆s ≤ 0.1s

but max.

0.5mm

Locally

permissible

if ending

flat and

∆s ≤ 0.1s

but max. 1

mm

Permissible

if ending

flat and

∆s ≤ 0.15s

but max.

5mm

Joint faces are displaced relative

to one another or thickness

variations are not adjusted

Permissible

if

e ≤0.1s but

max 2 mm

Permissible

if

e≤0.15s but

max 4 mm

Permissible

if

e≤0.2s but

max 5 mm

For example:

• Machine fault

• layout fault

Permissible

if

e ≤1 mm

Permissibile

if

e ≤ 2 mm

Permissibile

if

e ≤ 4 mm

Excessive and sharp edged

welding flash over part all of

weld length or weld girth due to

wrong welding parameters,

especially caused by an

excessive joint pressure with

polyolefin’s only

Not

Permissible

Not

Permissible

Not

Permissible

Loading...

Loading...