8 Fusion Operating instructions SG 160

36

8.2.3 Failure Analysis in Socket Fusion

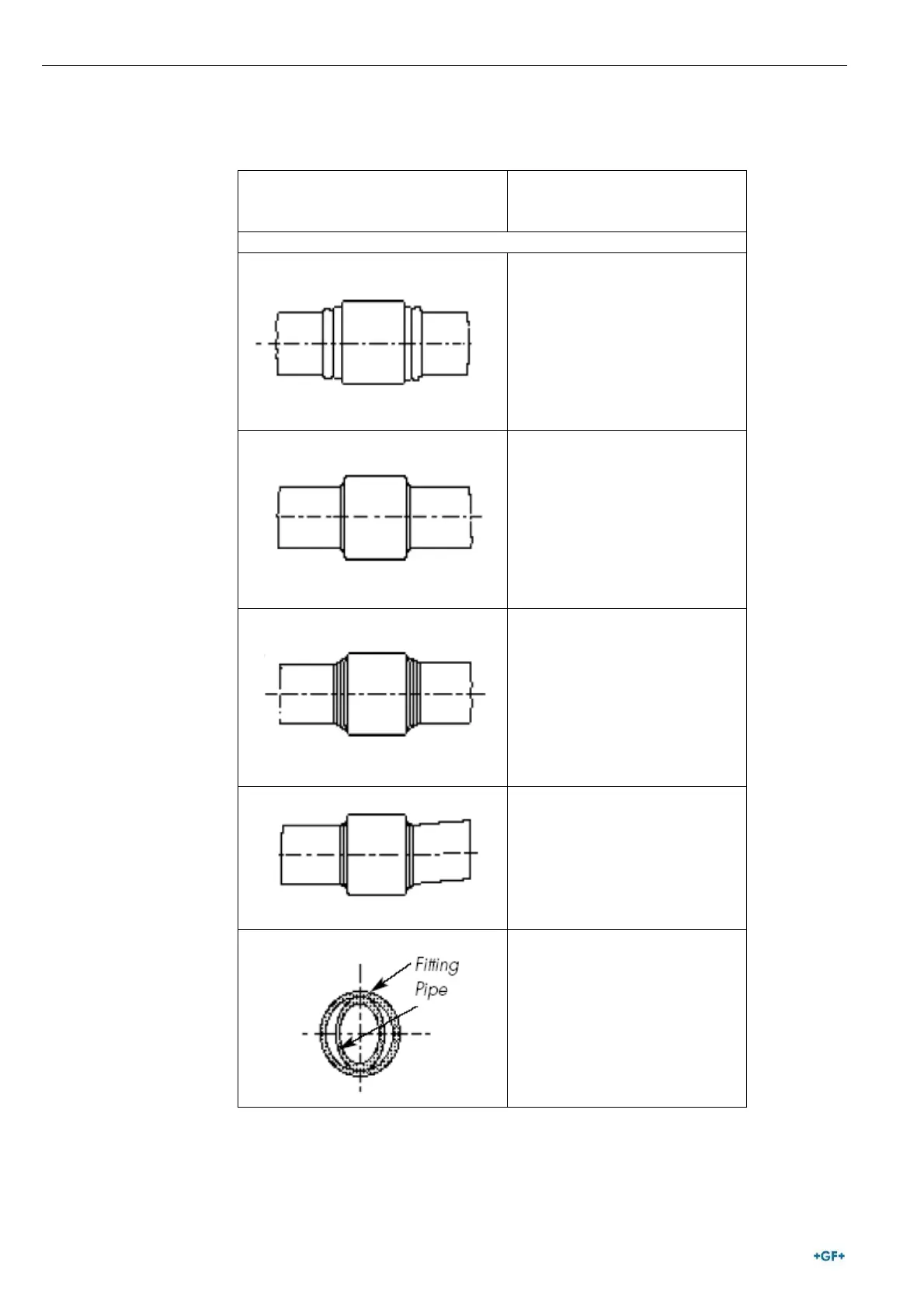

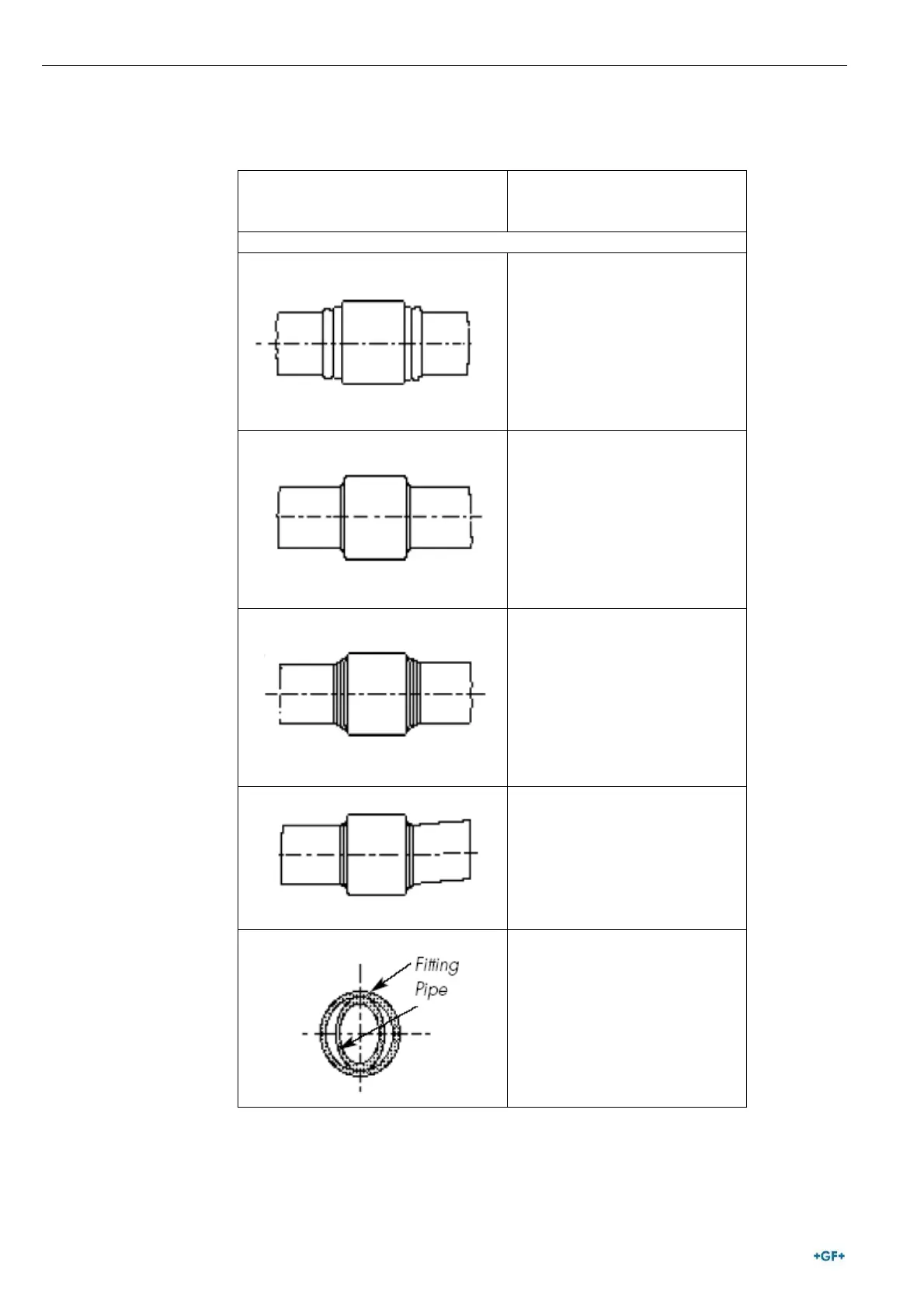

Feature Description

Internal state of joint

Different bead formation or no bead

on one or both sides (over the entire

joint length or only a part). Possible

cause:

• heating element temperature

too high

• heating time too long

• inadmissible tolerances

Different bead formation or no bead

on one or both sides (over the entire

joint length or only a part). Possible

cause:

• heating time too short

• heating element temperature

too low

• inadmissible tolerances

Different bead formation or no bead

on one or both sides (over the entire

joint length or only a part). Possible

cause:

• unworked fusion surface

• soiled fusion surface

• heating element temperature

too high

A pipe joined at an angle on one or

both sides to the fitting, with or

without some stress, for example

due to alignment error.

Distorted or oval-shaped pipe end

or fitting with local fusion pressure

being too low, for example. Possible

cause:

• bend radius at collars too low

• pipe/fitting incorrectly stored

• clamped too hard in clamping

device

Loading...

Loading...