Operating instructions SG 160 8 Fusion

37

Feature Description

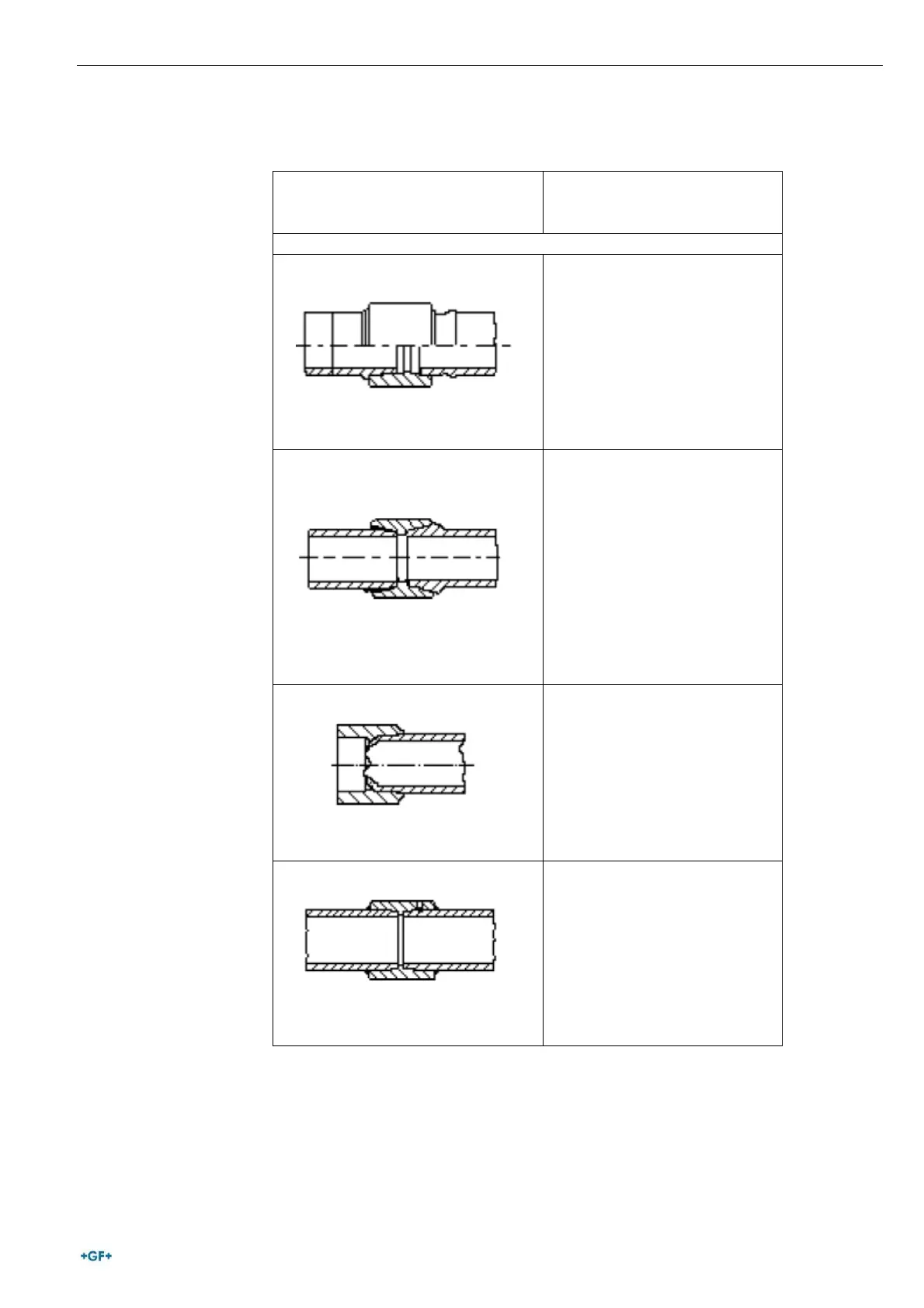

Internal state of joint

Insufficient fusion joint length with

completely or only partially melted

fusion surface. Possible cause:

• heating time too short

• pipe ends not right-angled

• heating element

temperature too low

• pipe/fitting slipping away

• change-over time too long

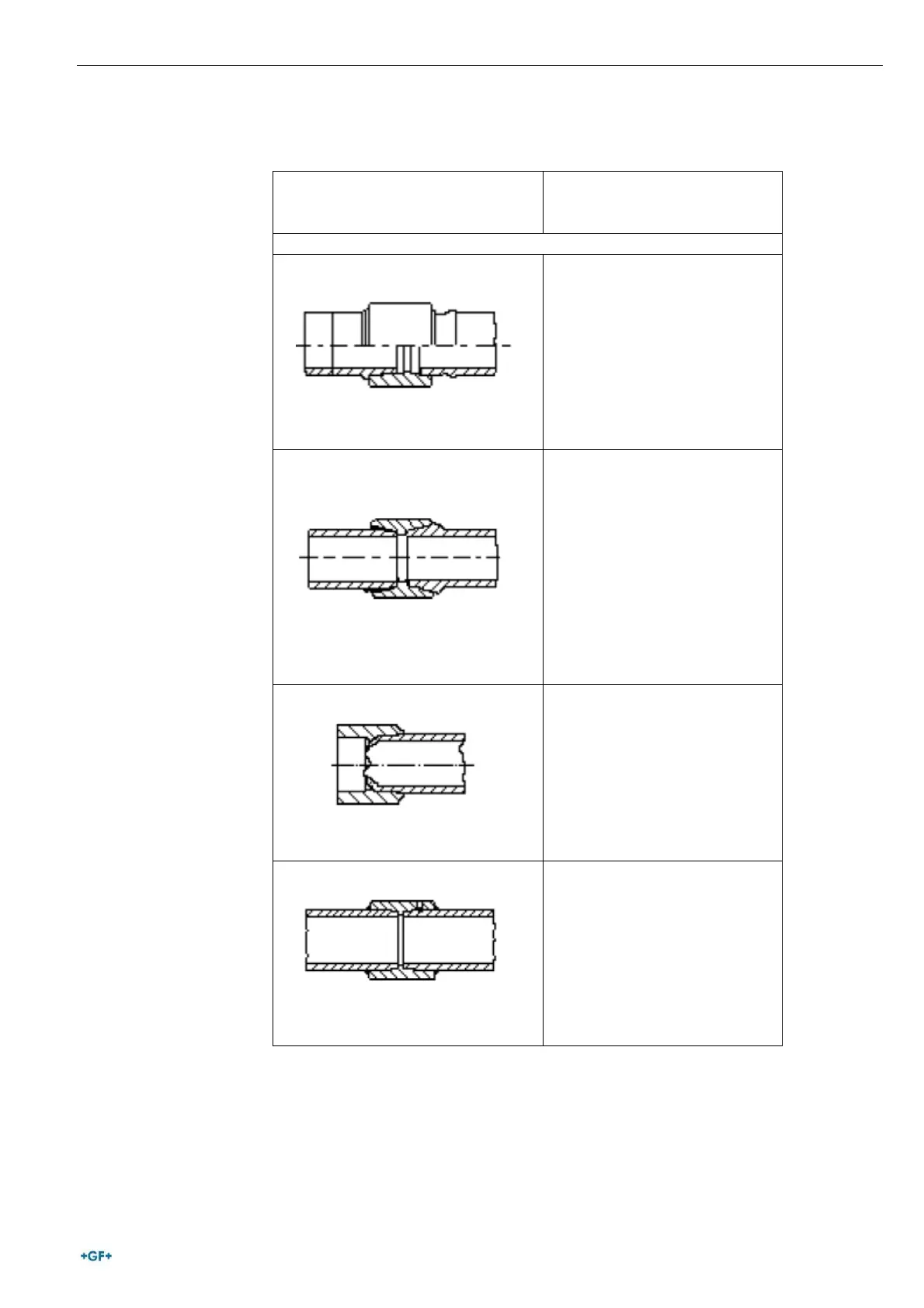

Jointing error with insufficient form-

locking Local, axially on surface or

circular formation of channel.

Possible cause:

• notches in the pipe surface

• diameter tolerance of pipe

or fitting exceeded

• incorrect mechanical

working

• pipe not aligned with

fitting

Compressed pipe cross-section

during heating or fusion. Possible

cause:

• fusion pressure too high

• fusion of thin-walled pipes

• heating time too long

• fusion temperature too

high

Pores due to foreign substances

Single, very widespread or local

concentrations of pores or

inclusions. Possible cause:

• vapors formed during

fusion (water, solvents)

• soiled heating element

Loading...

Loading...