9 Fusion data Operating instructions SG 160

38

9 Fusion data

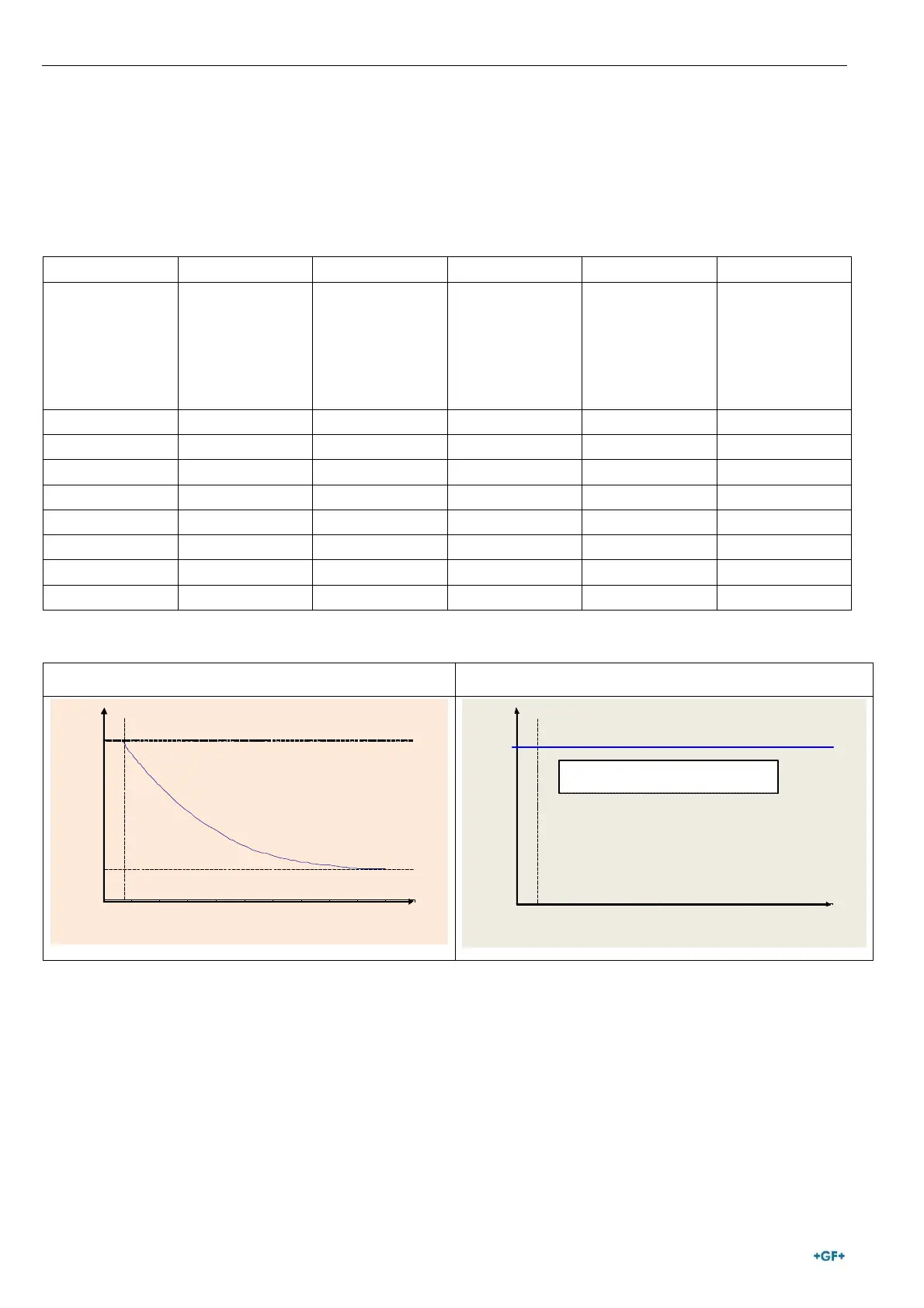

Heating element butt fusion of PE

Fusion chart according to DVS 2207-1

thickness

Bead height on

heating element after

equalization

(equalization at

0.15N/mm

2

)

Heat soak time = 10 x

wall thickness (heat

soak at 0.01 N/mm

2

)

Time until max

pressure reached

Cooling time at fusion

pressure

p = 0.15 N/mm

2

± 0.01

(min.value)

(max. time)

(min.value)

up to 4.5 0.5 45 5 5 6

4.5 – 7.0 1.0 45 – 70 5 – 6 5 – 6 6 – 10

7.0 – 12.0 1.5 70 – 120 6 – 8 6 – 8 10 – 16

12.0 – 19.0 2.0 120 – 190 8 – 10 8 – 11 16 – 24

19.0 – 26.0 2.5 190 – 260 10 – 12 11 – 14 24 – 32

26.0 – 37.0 3.0 260 – 370 12 – 16 14 – 19 32 – 45

37.0 – 50.0 3.5 370 – 500 16 – 20 19 – 25 45 – 60

50.0 – 70.0 4.0 500 – 700 20 – 25 25 – 35 60 – 80

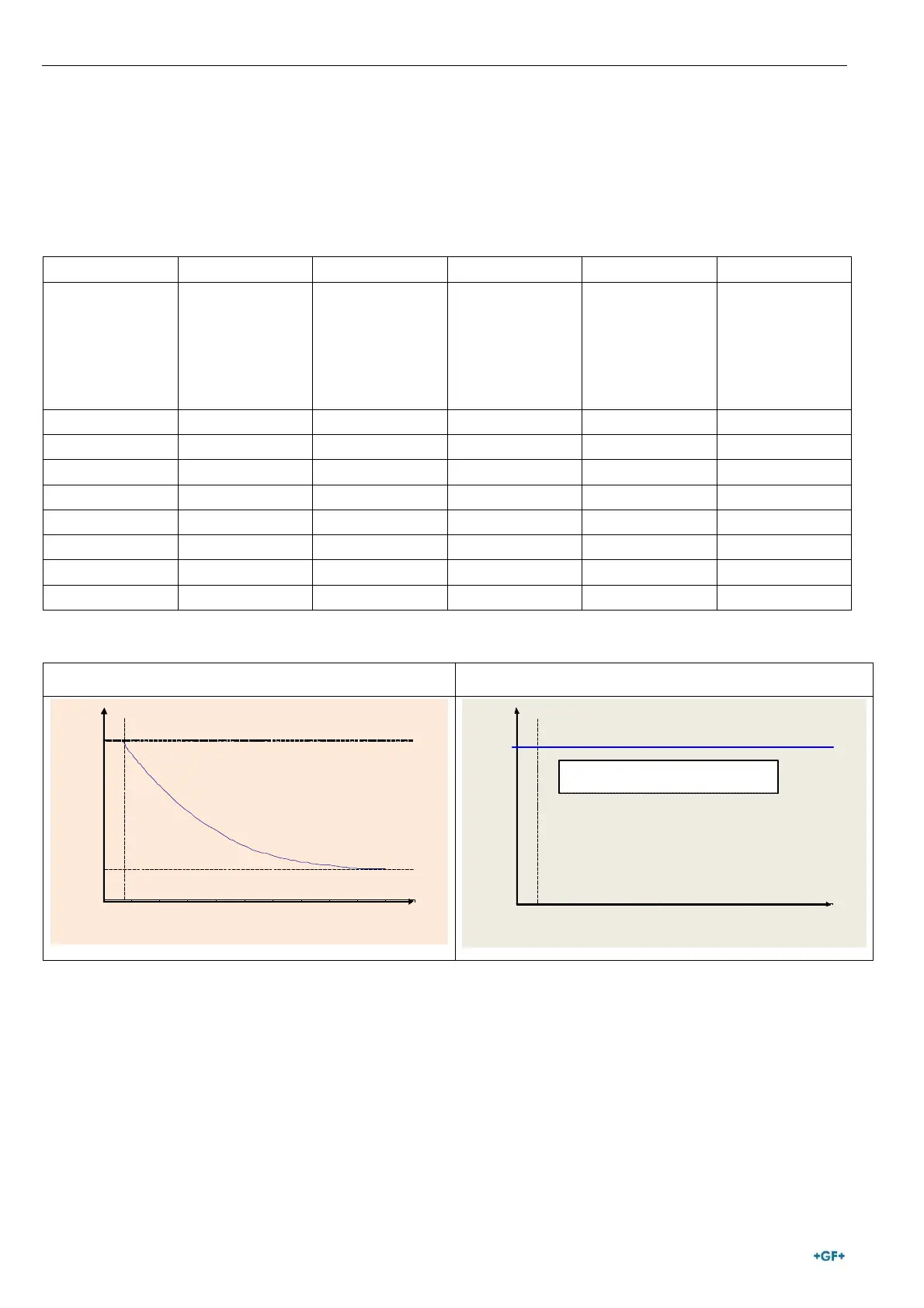

Diagram of standard values for heater temperatures in relation on pipe wall thickness

HD-PE (PE 80) PE 100

195

200

215

220

225

Pipe wall thi ckne ss / Ro hrwanddicke /Spessore tu bo mm

°C

1 95

2 05

2 10

2 20

0

5

10

15

20

25

30

35

40

4 5

55

Pipe w al l thi ckn ess / Rohrwanddicke /Spessore tubo mm

°C

T = 220°C = constant

Loading...

Loading...