16

ENGLISH

09

Now insert the plastic wheel in its housing again, and check through

the hole that the internal spring hook is perfectly coupled (Photo 10),

10

place the springs, the teeth for the starter jaw and screw the cover again

using medium thread-locker.

All the parts in movement, including the springs, must be well lubricated.

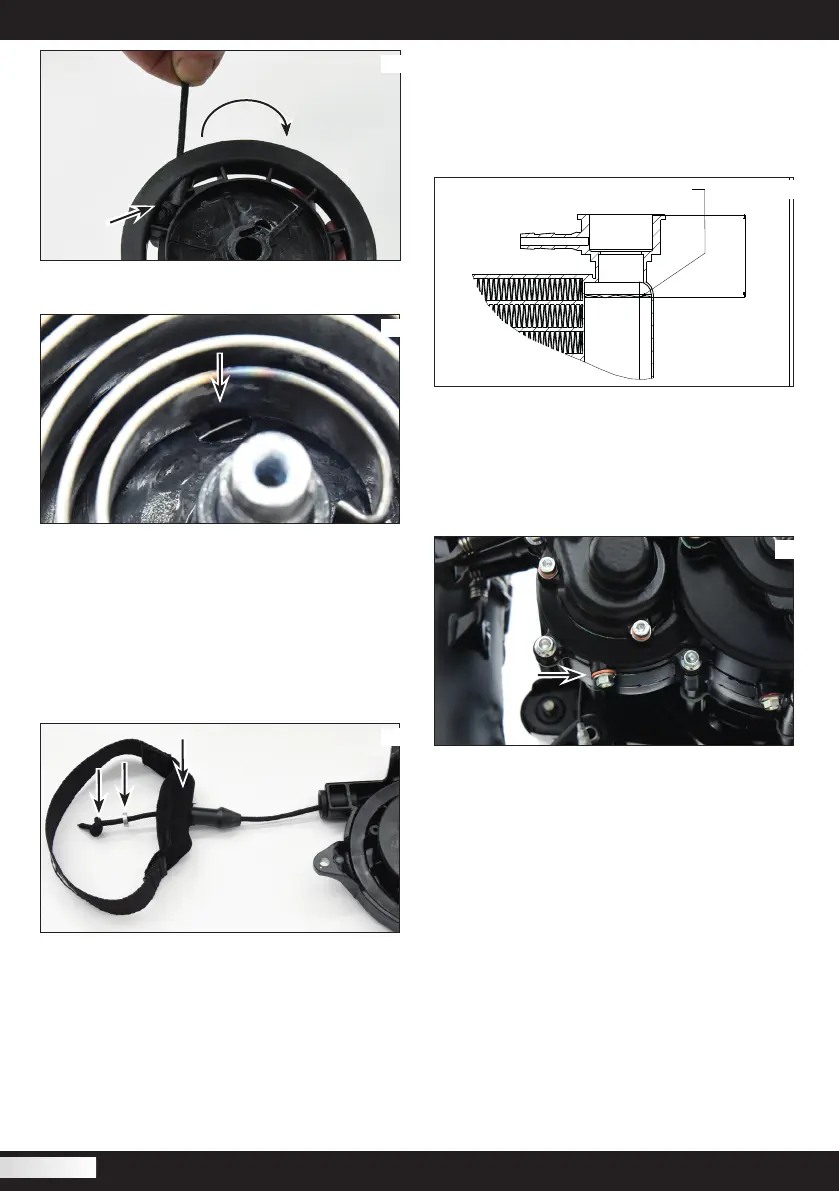

Now go on by charging the return spring: take the head of the rope

leaving 10-20 cm coming out the hole with “u” shape on the wheel

side. Turn the wheel 6,5 times in counter clock-wise sense till it stops in

front of the exit hole on the aluminium case. Keeping the plastic wheel

stopped, pass the rope through the case hole. Insert the handle and the

washer and tie a single knot as shown in (photo 11).

11

! ATTENTION! verify that the return spring does not reach the end

of the stroke. Extract the rope completely and turn the wheel again to

check that it can make at least one turn before stopping.

This test is very important because the spring hasn’t been studied to

reach the end of the stroke and, if it happens, the spring will break.

Reassemble the starter in the engine and tight the 4 screws (M5) with

strength (see the tightening torque values table).

9.5- COOLANT SYSTEM CHECK

Periodically check the cooling system: when the engine is cold, the coo-

lant must cover the last element of the radiator. (Photo 12) If necessary

add some liquid, using the one specific for aluminium radiator.

! ATTENTION: never open the cap when the engine is hot, you

could burn

Materiale

HRC

UNI Stato

STATO DELLE SUPERFICI

HB Disegno N

Codice

Disegnato

TOLLERANZE GENERALI

Denominazione

Stato Avanzamento

Dimens. da:

Toller.

a: 6

0

0.1

OLTRE

30

0.2

6 30

120

0.3

360

30'

120

0.5

0

Data

Scala

Peso [grammi]

3032,95

28/04/18 1,000

PELLICIOLI

RADIATORE THOR 202

alluminio

SCK-0601

011.3787

exp

C

Trattamento

VERNICIATO NERO

In fase di elaborazione

NON VALIDO PER PRODUZIONE

A termini di legge ci riserviamo la proprieta'di questo disegno

con divieto di riprodurlo o di renderlo comunque noto a terzi

COOLING LIQUID LEVEL

35-40

12

9.6- COOLING LEVEL EMPTYING

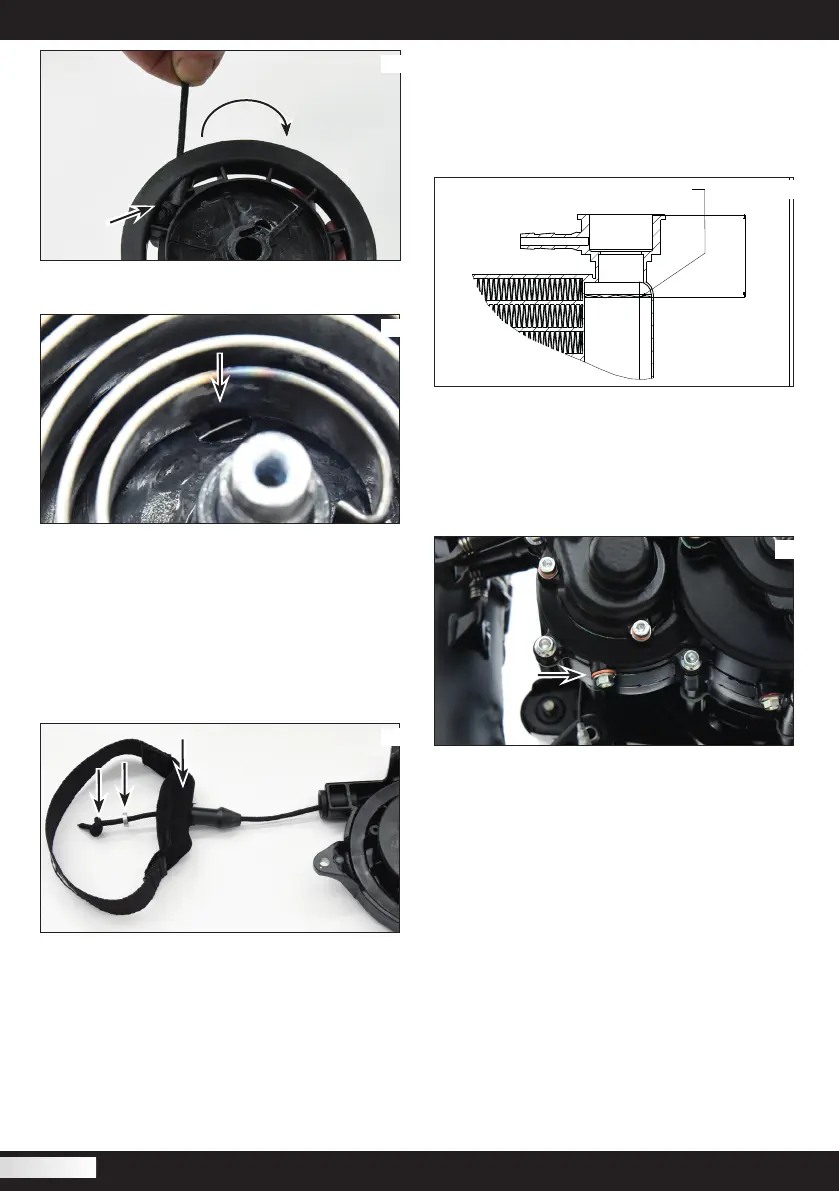

If necessary, empty the cooling system by unscrewing the proper screw

(see photo 13) and collect the leaking liquid. Remove the cap to make

this operation easier.

! ATTENTION: Do not empty it when the engine is hot, you could

burn.

13

9.7- COOLING SYSTEM FILLING

Fill in the cooling system using coolant specific for aluminium radiator

till covering the last element of the radiator. (photo 12). To make the

filling easier and to eliminate possible air bubbles, press repeatedly the

pipe at the base of the radiator to check the proper level of the liquid.

It is recommended running the engine for some seconds and check the

level again.

! CAUTION! Check the coolant before each using.

10- BEHAVIOUR IN FLIGHT

Maximum acceleration is recommended only to take off (full power) or

when really necessary!

In order to avoid a poor mixture from acceleration/ascent to level flight

conditions, loosen the engine till a descending phase and then gradually

accelerate again till achieving a level flight or a glide angle or a rise

angle wished. In this way you will be sure to maintain firm and effi-

cient the carburation, avoiding being over rpm with a minimum valve/

throttle opening.

We remind you that two stroke engines do not stand constant range for

Loading...

Loading...