8

CAUTION: RISK OF PERSONAL

INJURY AND PROPERTY DAMAGE.

Ensure the shoe is locked into position

before using tool.

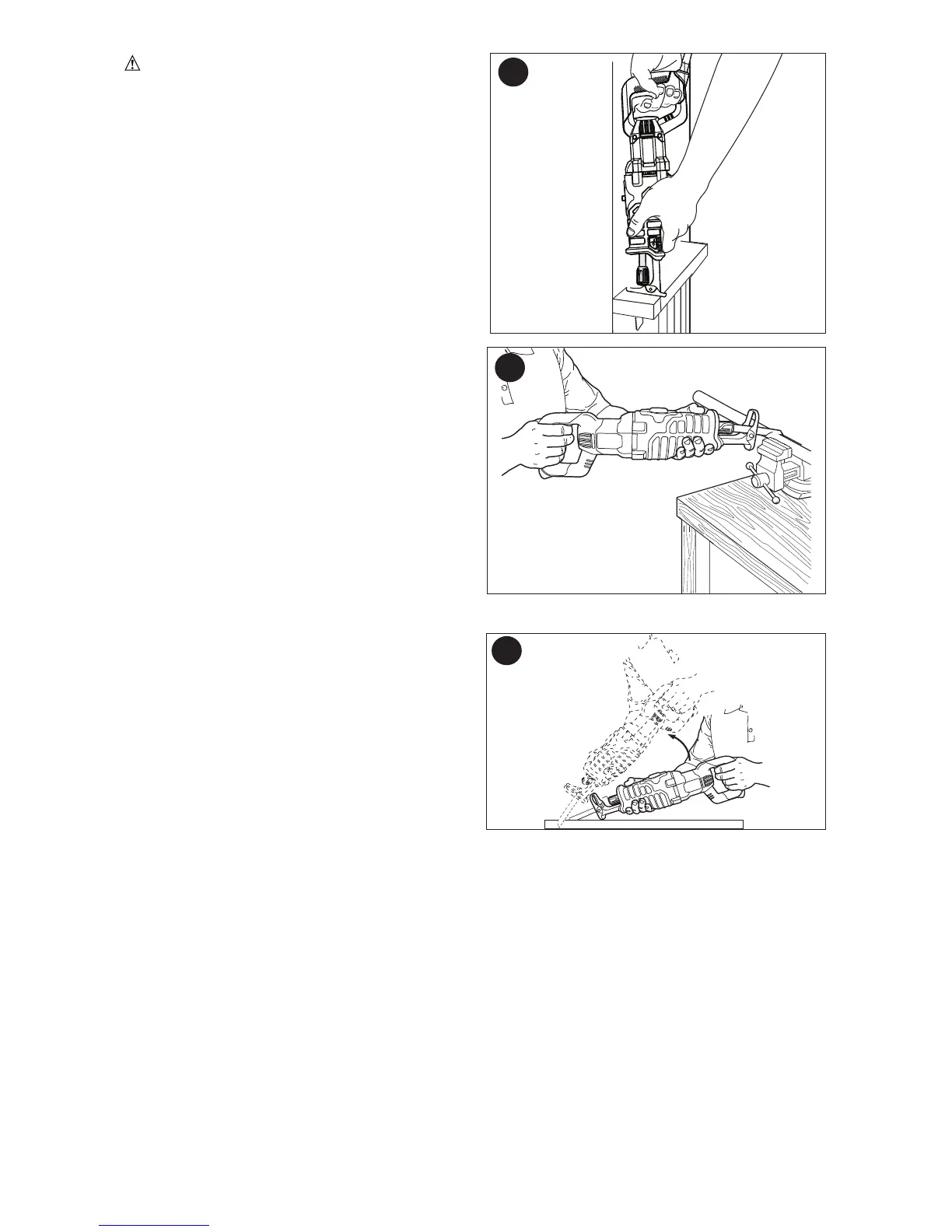

FLUSH CUTTING (FIGURE 7)

• The compact design of the reciprocating

saw motor housing and pivoting shoe

permit close cutting to floors, corners and

other difficult areas.

• To maximize flush cutting capabilities,

insert the blade shaft into the blade clamp

with the teeth of the blade facing up.

• Turn the saw upside down so you are as

close to the work surface as possible.

METAL CUTTING (FIGURE 8)

• Use a finer blade for ferrous metals and a

coarse blade for non-ferrous materials.

• In thin gauge sheet metals it is best to

clamp wood to the underside of the sheet.

This will ensure a clean cut without

excess vibration or tearing of metal.

• Avoid forcing cutting blade as this

reduces blade life and causes costly

blade breakage.

NOTE: Spread a thin film of oil or other

coolant along the line ahead of the saw cut

for easier operation and longer blade life.

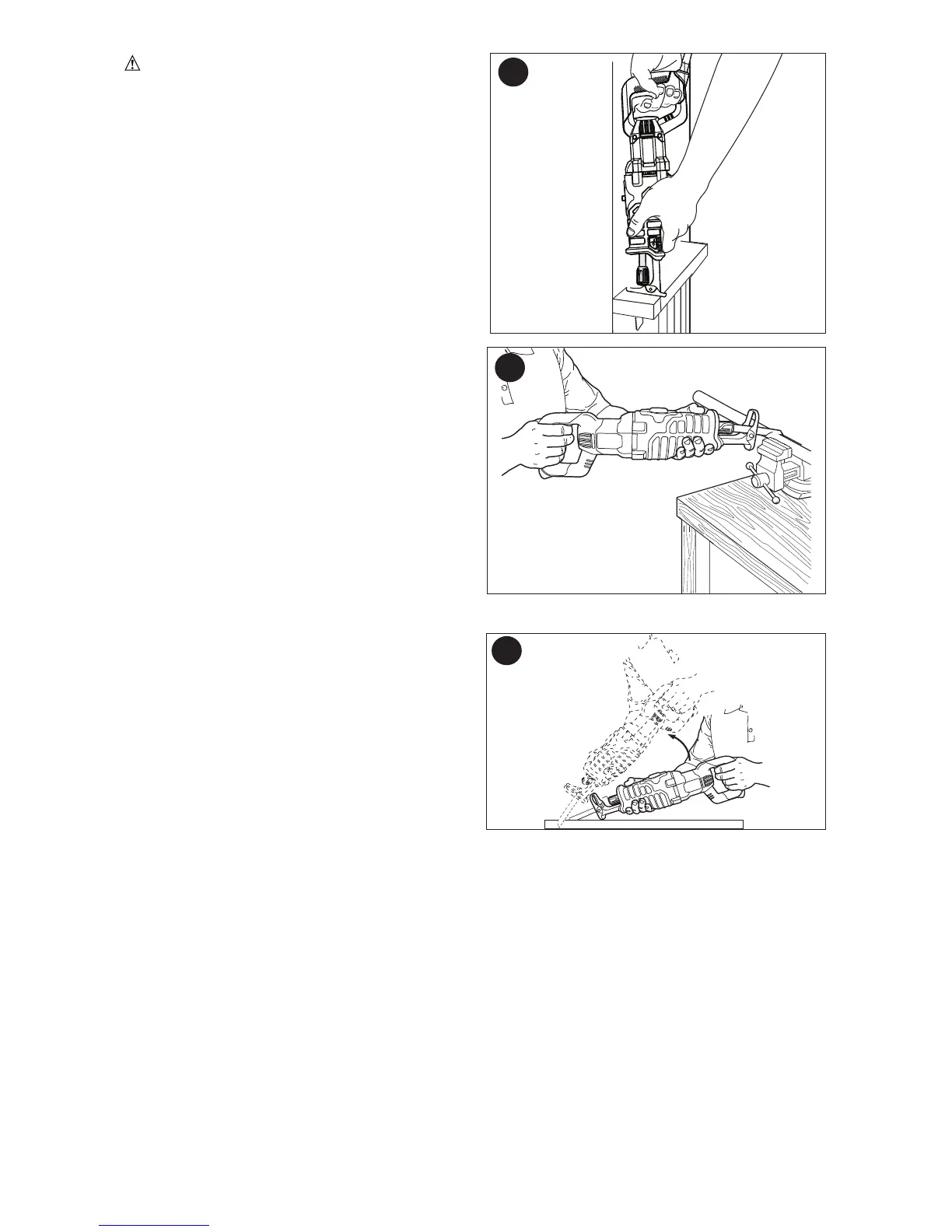

POCKET CUTTING - WOOD ONLY (FIGURE 9)

• Measure the surface area to be cut and

mark clearly with a pencil, chalk or

scriber.

• Insert blade in blade clamp and tighten

blade clamp securely.

• Tip the saw backward until the back edge

of the shoe is resting on the work surface

and the fully extended moving blade will

clear the surface.

• Grip unit with both hands, switch motor

on permitting blade to obtain maximum

speed.

• Begin a slow, deliberate upward swing with the main handle of the saw.

• The blade will begin to feed into material. Always be sure blade is completely

through material before continuing with pocket cut.

NOTE: In areas where blade visibility is limited, use the edge of the shoe as a guide.

PROJECT TIPS

• Cut only with sharp blades; they cut cleaner, faster and put less strain on the motor

while cutting.

• When cutting, always ensure that the shoe is held firmly against the workpiece and

the workpiece is secured from moving/deflecting. This will improve operator control

and minimize vibration.

• For longer blade life, use bi-metal blades. These utilize a carbon steel back welded

to high speed steel teeth making the blade more flexible and less prone to breaking.

8

9

Loading...

Loading...