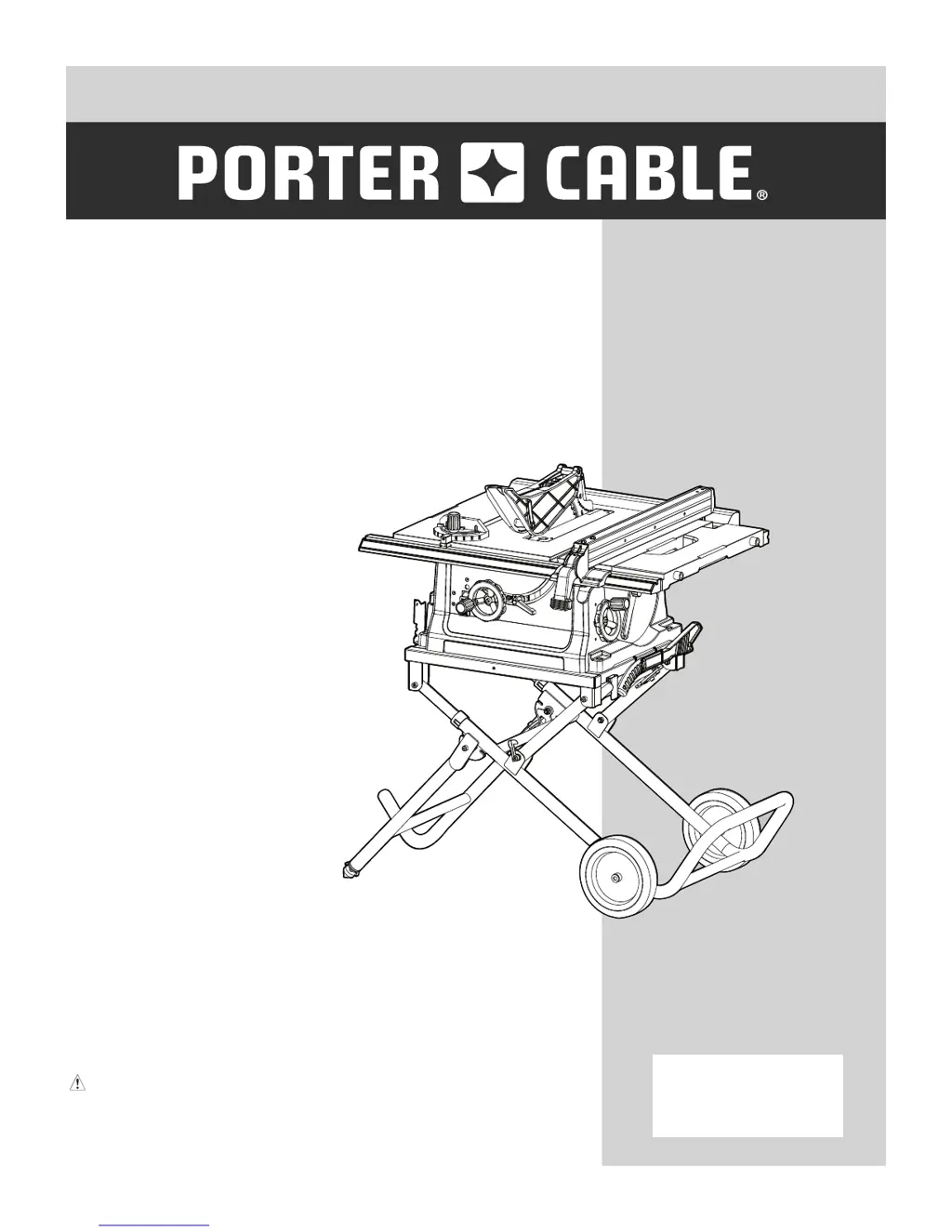

How to fix a Porter-Cable pcb220ts that will not start?

- WWanda NewmanAug 16, 2025

If your Porter-Cable Saw won't start, there are several possible causes: * The saw might not be plugged in. If this is the case, plug it in. * A fuse might be blown, or a circuit breaker tripped. If so, replace the fuse or reset the circuit breaker. * The cord could be damaged. If this is the case, have the cord replaced by a Porter-Cable Service Center or Authorized Service Station.