page no. 53 of 68

LX Range Users, Installation & Servicing Instructions Doc Ref M110 issue 1.0 Dec 2020.

2.6 Commissioning and Testing

‘O’ ring

Adjustment nut (9mm)

for minimum pressure setting

Adjustment nut (7mm)

for maximum pressure setting

Cap

Shaft

6.3mm AMP terminals

5. Turn off the main burner,

6 Press and hold the ENGINEER TEST button for 2

seconds. Disconnect the manometer and tighten the

sealing screw in the gas valve.

2.6.7. Final Adjustments

1. After checking or setting the burner pressures, the flue

gas composition must be checked with a gas analyser by

sampling within the first section of flue fitted to the flue

outlet of the unit.

2. Remove the flue sample cover plug (if fitted) and insert

a calibrated gas analyser.

3. Operate the burner(s) and allow the flue gas

temperature to stabilise.

4. Take readings for both low and high fire. These figures

will also be required for the commissioning sheet.

The resulting CO/CO2 ratio must conform

to current directives and rules in force

for non-domestic gas fired heaters.

5. Test for gas tightness around pressure test joint using

a leak detection fluid e.g. soap solution. Replace access

panel.

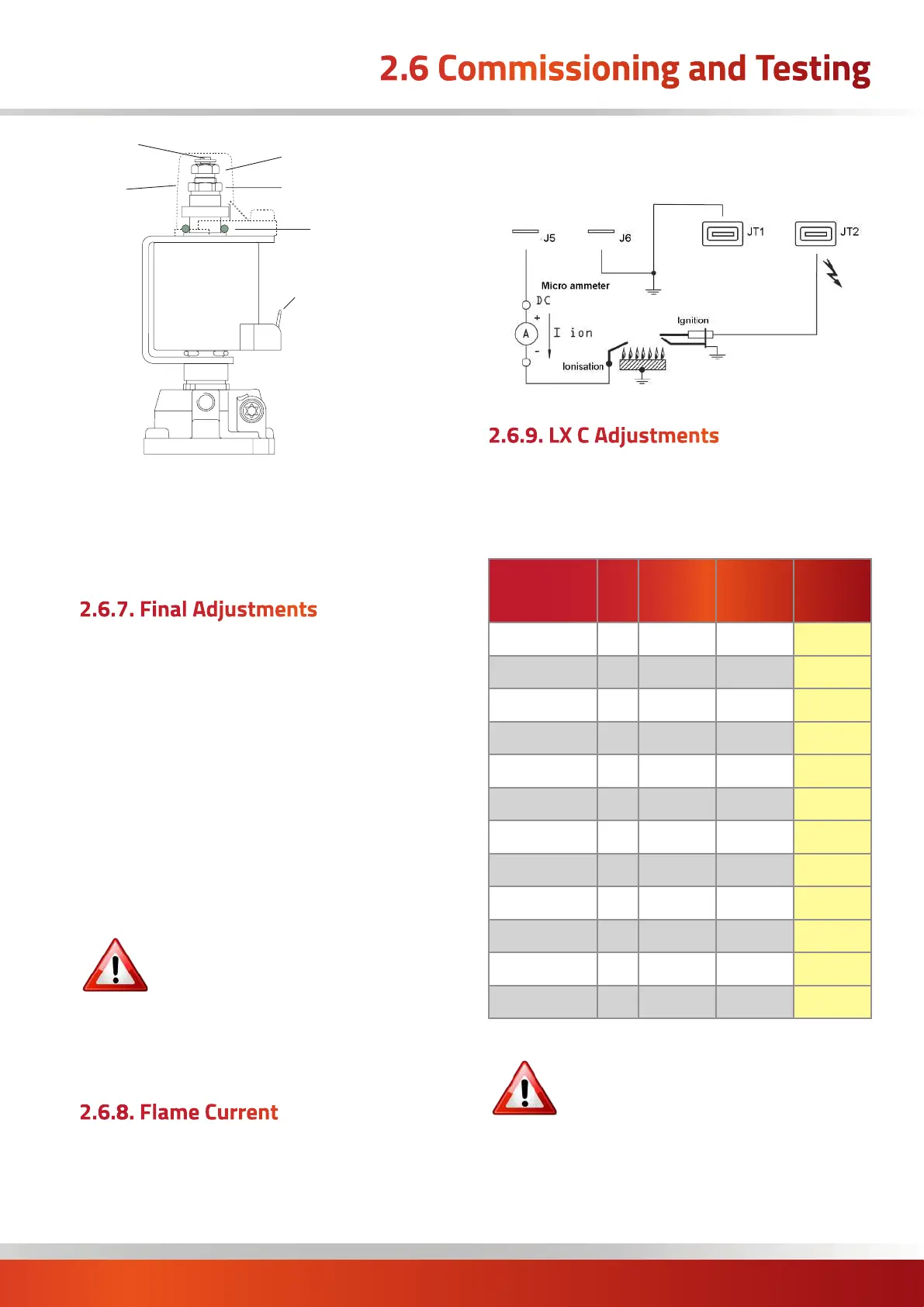

2.6.8. Flame Current

1. To measure the flame current connect a multimeter

capable of measuring micro amps as shown in the

following diagram.

2. Minimum current reading is 0.5µA and normal value

should be 1.5µA or higher.

Flame Current

Measurement

2.6.9. LX C Adjustments

Using a clamp meter around the fan power cable and with

all side panels closed, check the running current of the

centrifugal fan once the heater is running and compared

with the table below. * currents shown for each fan

Model

Pha

Motor

kW

Typical

Running

Current

Max

Running

Current

LX15 1 0.55 2.0A 5.0A

LX20 1 1.1 3.1A 5.5A

LX25 1 1.1 4.2A 5.5A

LX30 1 1.6 4.3A 8.0A

LX35 1 1.6 4.7A 8.0A

LX40 1 1.6 5.8A 8.0A

LX50 1 2.0 7.6A 9.8A

LX60 1 2.2 10.0A 10.0A

LX70 1 2.2 11.0A 11.0A

LX90 1 2 x 1.6 6.4A* 8.0A*

LX120 1 2 x 2.2 8.5A* 10.0A*

LX140 1 2 x 2.2 10.0A* 10.0A*

WARNING: Exceeding the MAX running

current will cause the fan’s thermal overload

to trip!

Adjust the balancing dampers within the airflow ductwork

system to achieve a current suitable for the model in

question.

Loading...

Loading...