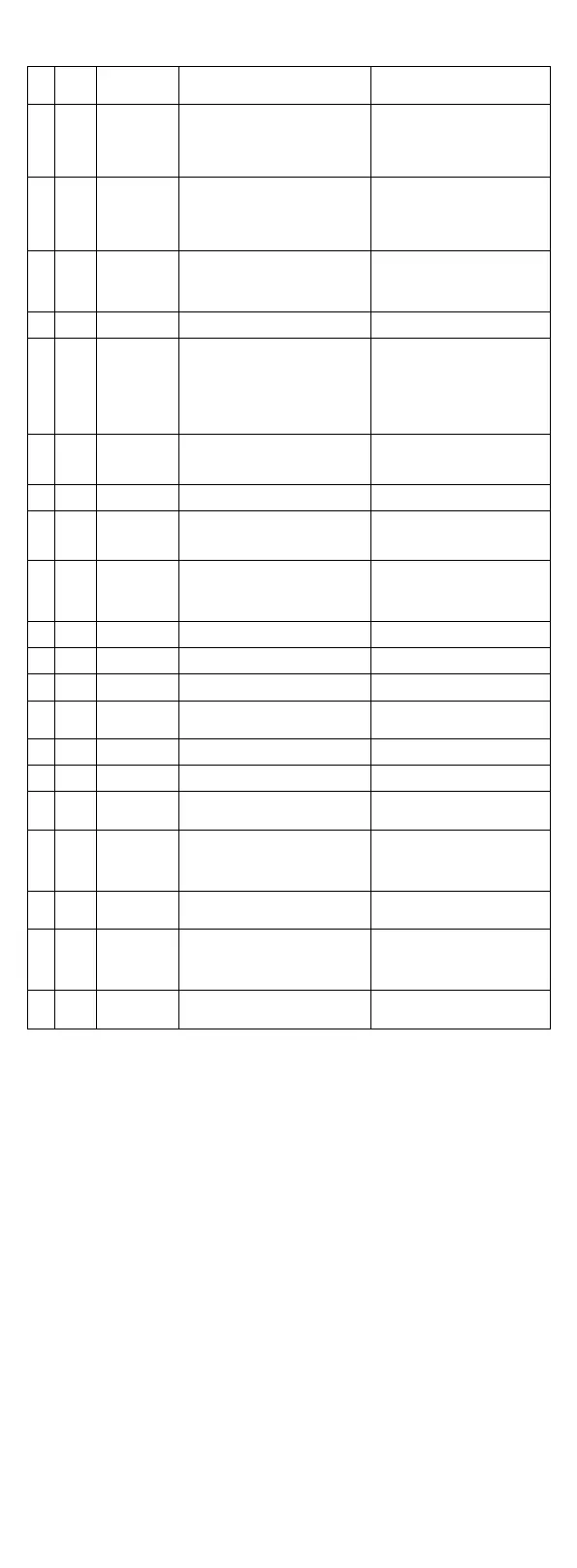

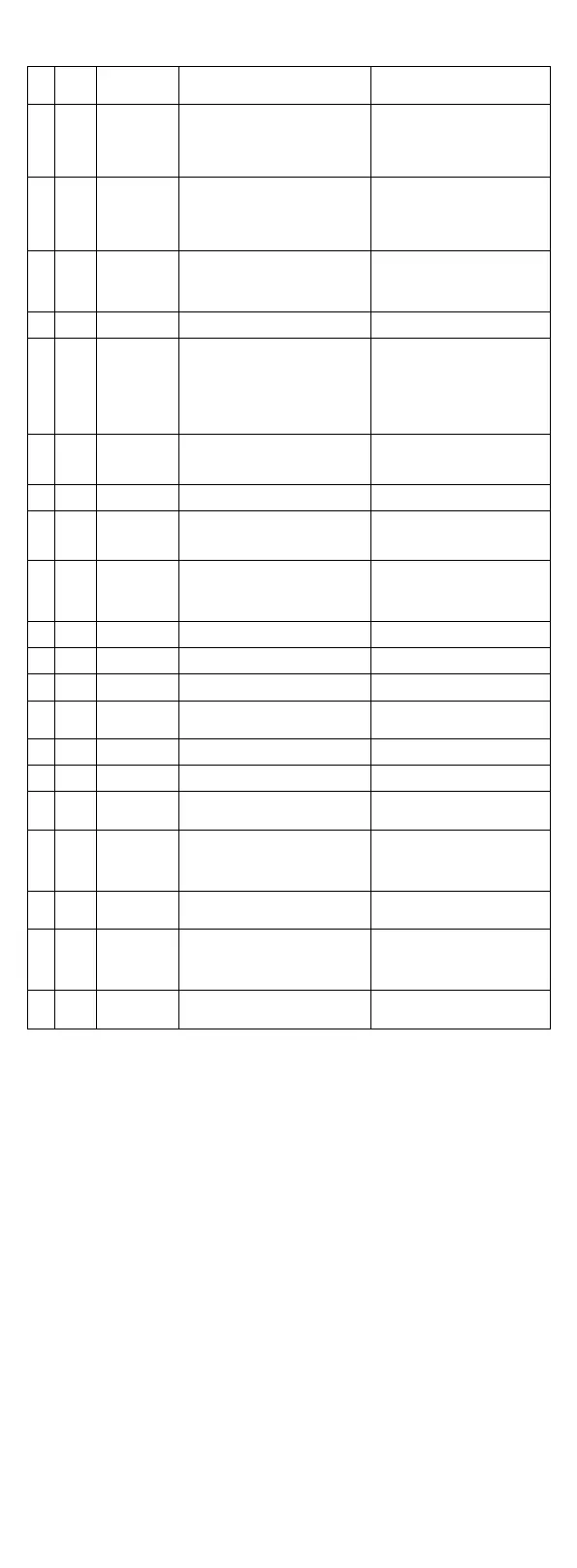

15 / 16

not

3.whether the load is too large or the

motor stall occurs

motor and its mechanical

conditions

1.The drive panel is abnormal.

2.The lightning protection plate is

abnormal

3.The main control panel is abnormal

4.The three-phase input power is not

normal

1.Replace the drive, the power

board or contactor

2.Seek for technical support

3.Check and eliminate the existing

problems in the peripheral line

1.The lead wires from the inverter to

the motor is not normal

2.The inverter's three phase output is

unbalanced when the motor is running

3.The drive panel is abnormal.

4.The module is abnormal

1.Eliminate peripheral faults

2.Check the motor's three-phase

winding is normal or not and

eliminate faults

3.Seek for technical support

1.The air duct is blocked

2.The fan is damaged

3.The ambient temperature is too high

4.The module thermistor is damaged

5.The inverter module is damaged

1.Clean up the air duct

2.Replace the fan

3.Decrease the ambient temperature

4.Replace the thermistor

5.Replace the inverter module

Input external fault signal through the

multi-function terminal DI

1.The communication cable is not

normal

2.The settings for communication

expansion card F9.07 are incorrect

3.The settings for communication

parameters F9 group are incorrect

4.The host computer is not working

properly

1.Check the communication cable

2.Correctly set the communications

expansion card type

3.Correctly set the communication

parameters

4.Check the wiring of host computer

1.Input phase loss

2.The drive plate and the contact are

not normal

1.Check and eliminate the existing

problems in the peripheral line

2.Replace the drive, the power

board or contactor

1.Check Hall device

2.The drive panel is abnormal.

1.Replace the drive panel

2.Replace hall device

Motor

parameter auto

tuning fault

1.The motor parameters was not set

according to the nameplate

2.The identification process of

parameter is timeout

1.correctly set motor parameter

according to the nameplate

2.check the lead wire from the

inverter to the motor

1.The encoder is damaged

2.PG card is abnormal

3.The encoder model does not match

4.The encoder connection has error

1.Replace the encoder

2.Replace the PG card

3.Correctly set the encoder model

according to the Actual conditions

4.Eliminate the line fault

EEPROM read

and write fault

Replace the main control panel

1.Overvoltage

2.Overcurrent

1.Eliminate overvoltage fault

2.Eliminate overcurrent fault

Short-circuit to

ground fault

Replace the cable or motor

Cumulative

running time

arrival fault

Cumulative running time arrival fault

Clear history information by using

initialization function parameters

Input custom fault 1 signal through the

multi-function terminal DI

Input custom fault 2 signal through the

multi-function terminal DI

Total power-on

time arrival

fault

Total power-on time reaches the set

value

Clear history information by using

initialization function parameters

The inverter running current is less

than F8.31

Confirm whether the load is

removed or not or the settings for

parameter(F8.31, F8.32) accord

with the Actual operating

conditions

PID feedback

loss when

running fault

PID feedback is less than the set value

of E2.11

Check PID feedback signal or set

E2.11 to an appropriate value

Quick current

limiting fault

1.Whether the load is too large or the

motor stall occurs

2.The type selection of inverter is

small

1.Reduce the load and check the

motor and its mechanical

conditions

2.Choose the inverter with large

power level

Switch motor

when running

fault

Change current motor through the

terminal when the inverter is running

Switch motor after the inverter

stops

Loading...

Loading...