23

4. The work area jet range must be absolutely prohibited to

and free from objects that, inadvertently under a pressure

jet, can be damaged and/or create dangerous situations.

5. The water jet must always and only be pointed in the

direction of the work area, including during preliminary

tests or checks.

6. The operator must always pay attention to the trajectory

of debris removed by the water jet. Where necessary,

suitable guards must be provided by the Operator to

protect anything that could become accidentally exposed.

7. The operator should not be distracted for any reason

during work. Workers needing to access the operating area

must wait for the Operator to stop work on his/her own

initiative, after which they should immediately make their

presence known.

8. It is important for safety that all team members are always

fully aware of each other’s intentions in order to avoid

dangerous misunderstandings.

9. The high pressure system must not be started up and run

under pressure without all team members in position and

without the Operator having already directed his/her lance

toward the work area.

3.5 Safety during system maintenance

1. High pressure system maintenance must be carried out

in the time intervals set by the manufacturer who is

responsible for the whole group according to law.

2. Maintenance should always be performed by trained and

authorised personnel.

3. Assembly and disassembly of the pump and the various

components must only be carried out by authorized

personnel, using appropriate equipment in order

to prevent damage to components, in particular to

connections.

4. Always only use original spare parts to ensure total

reliability and safety.

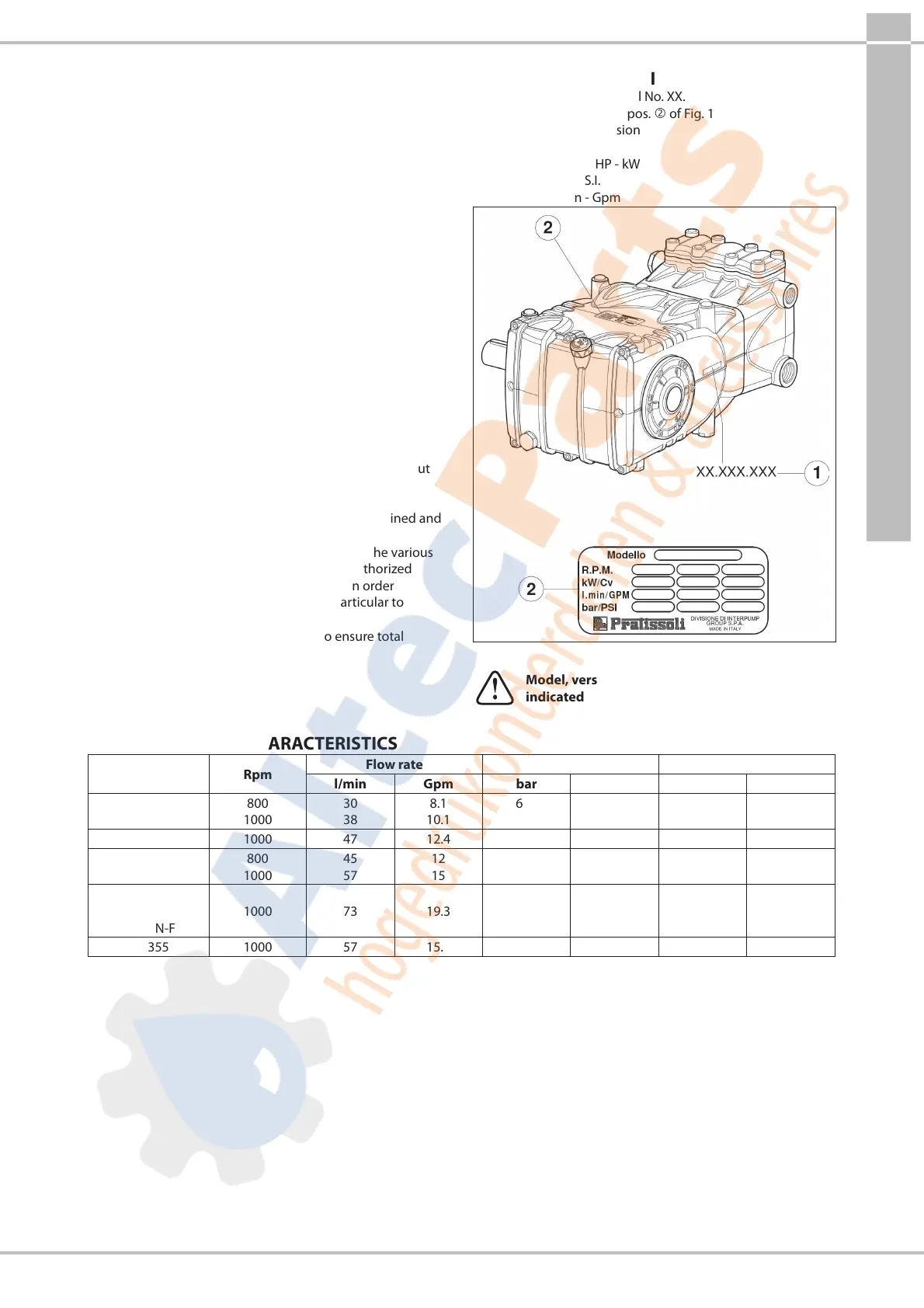

4 PUMP IDENTIFICATION

Each pump has its own Serial No. XX.XXX.XXX see pos.c and

an identication label, see pos.d of Fig.1 which shows:

- Pump model and version

- Max revs

- Absorbed power HP - kW

- Pressure bar - P.S.I.

- Flow rate l/min - Gpm

Fig.1

Model, version and serial number must always be

indicated when ordering spare parts

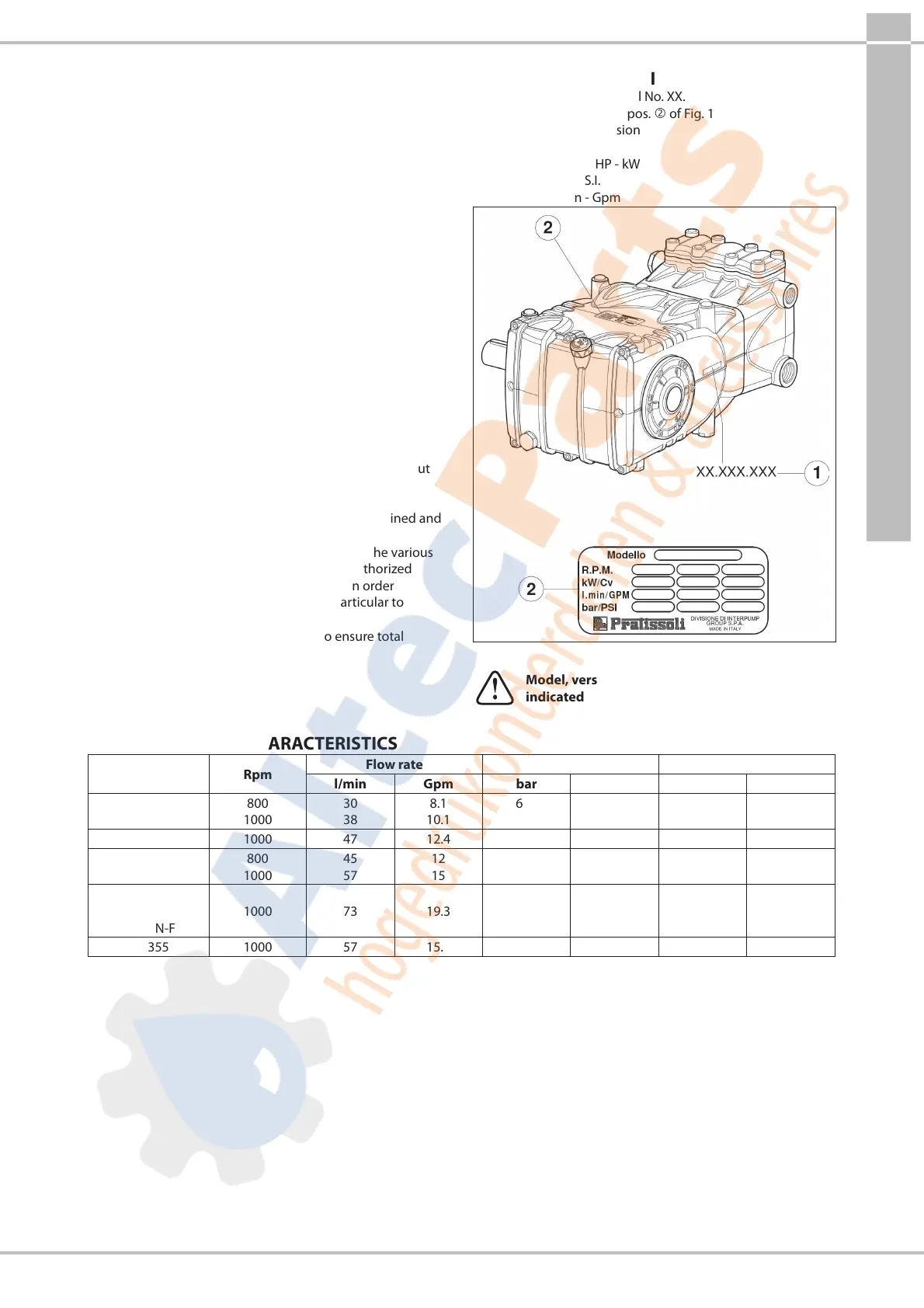

5 TECHNICAL CHARACTERISTICS

Model Rpm

Flow rate Pressure Power

l/min Gpm bar psi kW HP

HF 18

800

1000

30

38

8.1

10.1

600

500

8700

7250

35.5

36.8

48

50

HF 20 1000 47 12.4 400 5800 36.8 50

HF 22

800

1000

45

57

12

15

400

350

5800

5075

35.5

36.8

48

50

HF 25

HF 25N

HF 25N-F

1000 73 19.3 280 4060 36.8 50

WK355 1000 57 15.1 350 5075 38.1 51.8

Loading...

Loading...