18PM-1440BV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

burrs can be a problem, hone if necessary. If there are no

visible problems, the stud in question may need ad-

justment as follows:

• Remove the stop screw from the stud.

• If the cam marker in question can’t get to the rst Vee (3

o’clock), back the stud OUT one full turn, then replace the

stop screw.

• If the cam marker goes beyond the second Vee (6 o’clock),

screw the stud IN one more turn, then replace the stop

screw.

• If the markers are correctly aligned, repeat the tightening

sequence as step 3, light force. Repeat the sequence two

more times, rst with moderate force, then fully tighten.

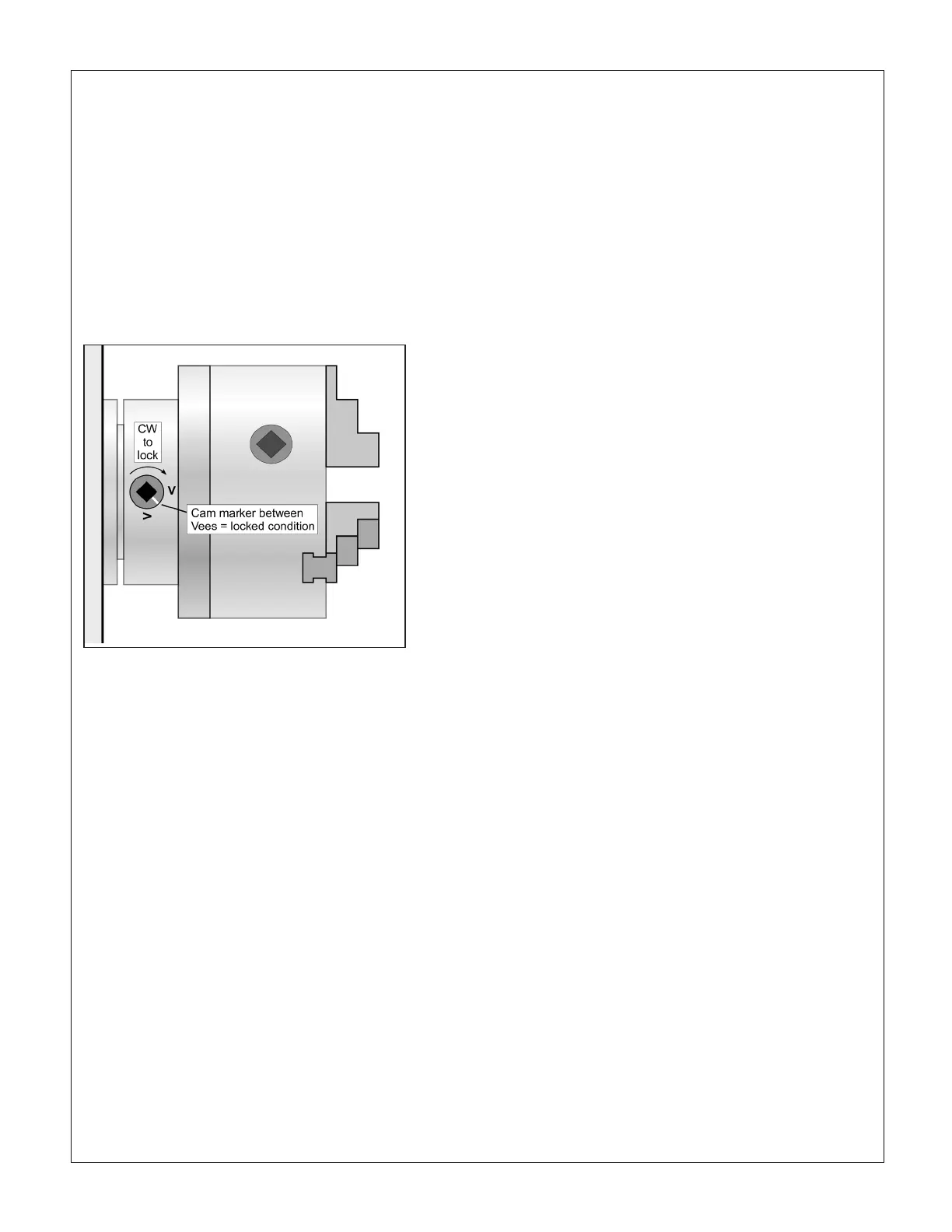

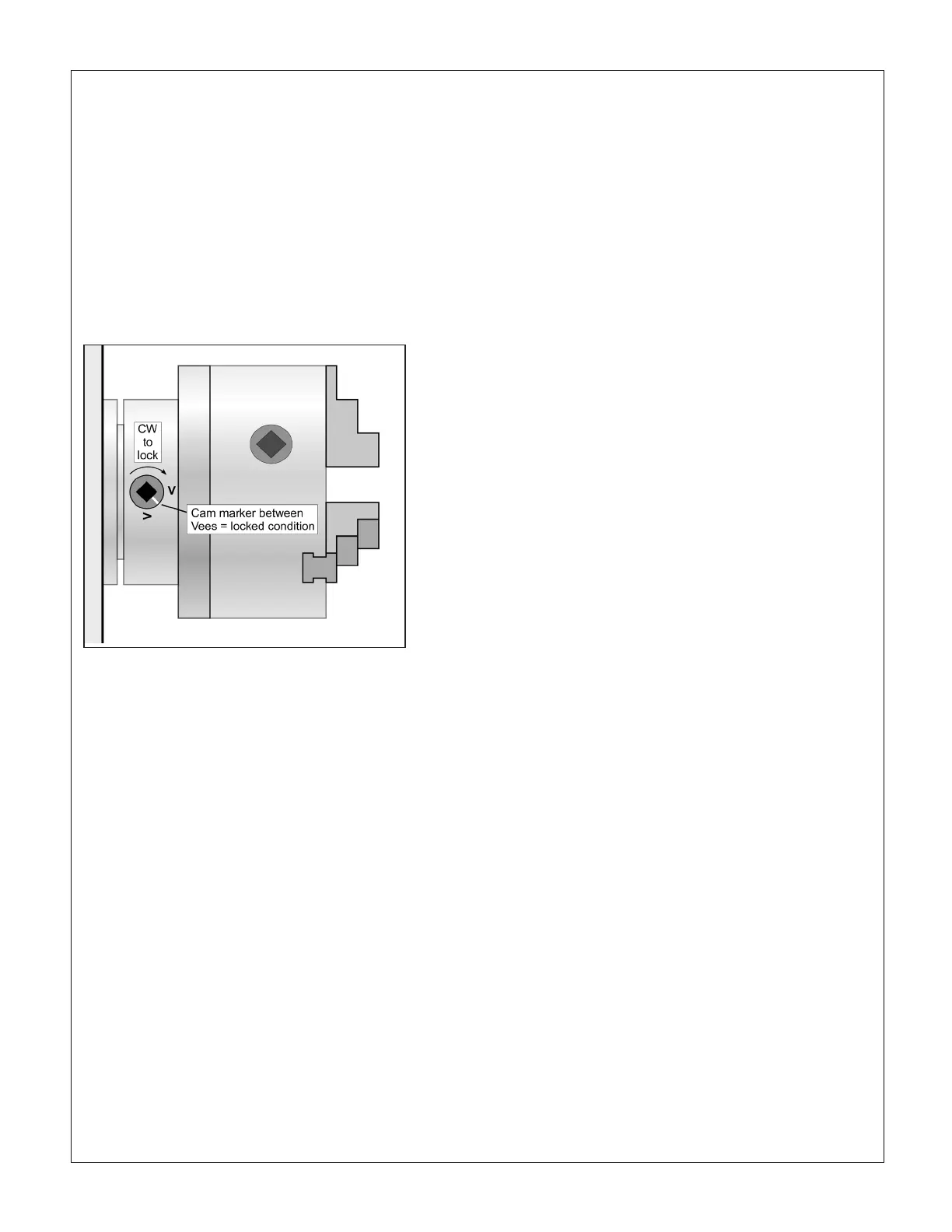

Figure 3-25 Cam in locked condition

TO REMOVE A CHUCK OR FACEPLATE

Disconnect the 220V supply from the lathe!

Protect the lathe bed, as Figure 3-23. While supporting its

weight, turn each of the cams to 12 o’clock, Figure 3-24, then

remove the chuck. If the chuck does not come free, try tapping

the backplate gently with a soft (dead blow) mallet.

Loading...

Loading...