14

PM 25MV v9 2021-12 Copyright © 2021 Quality Machine Tools, LLC

3. If the headstock has been tilted, reset it to the ap-

proximate zero degree position on the tilt scale, then

tighten the three nuts enough to avoid unexpected

headstock movement.

4. Remove the vise, if installed, and clean the table sur-

face. If there are noticeable grooves or dings, atten

the surface with a diamond lap or ne-grit stone.

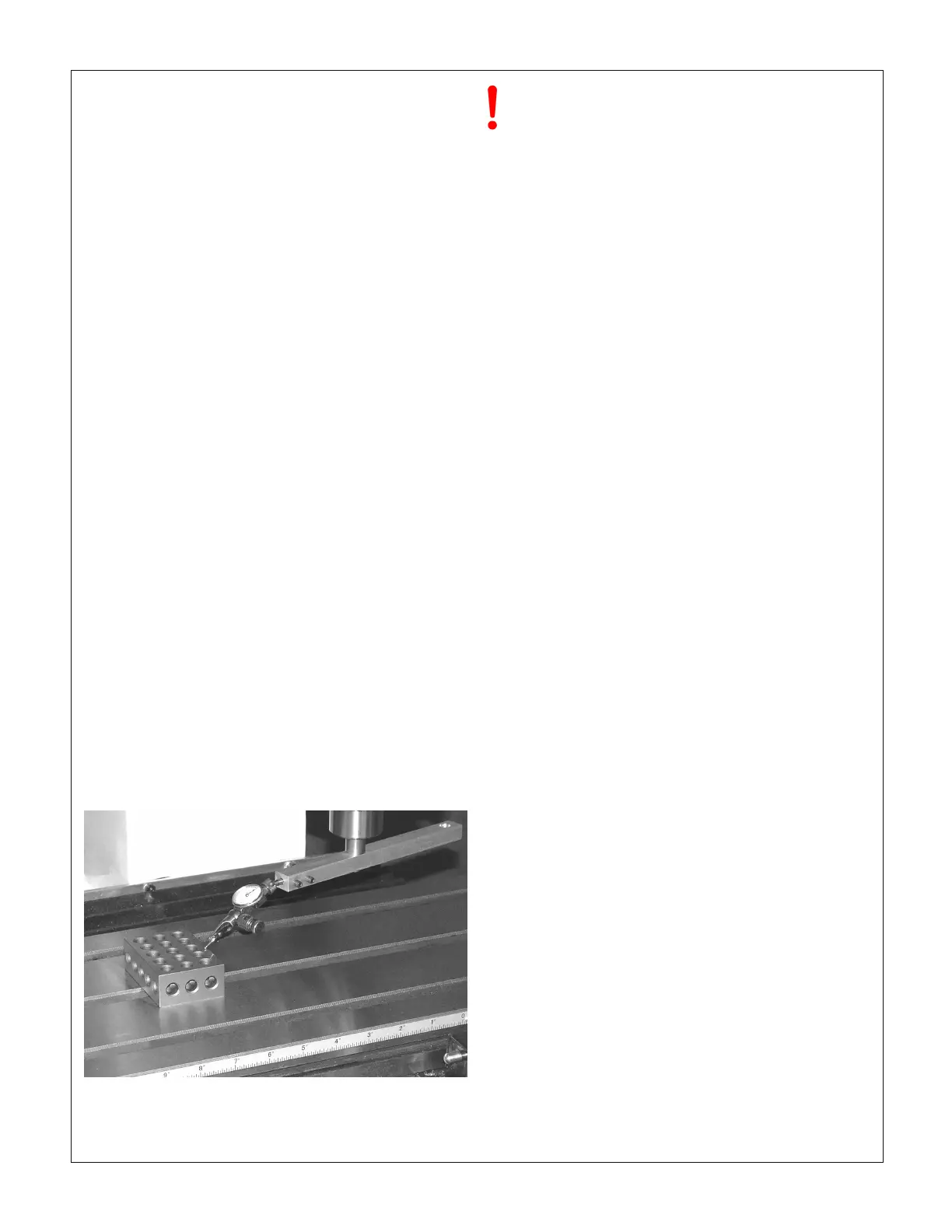

5. Set a 1-2-3 block (or other precision-ground block)

on the table under the indicator probe.

6. Switch on the DRO.

7. Using the ne downfeed lower the spindle to give an

indicator reading of about half-scale.

8. Note the dial indicator and DRO readings, then back

o the ne downfeed at least a couple of turns to

avoid collision when sweeping.

9. Reposition the 1-2-3 block to the opposite location

on the table.

10. Swing the indicator holder to the new location, then

lower the spindle – ne downfeed again – to give the

same dial indicator reading as in step (8).

If the headstock is perfectly trammed – highly unlikely

at the rst shot – the DRO reading should be as in step

(8). If not, loosen the nuts just enough to allow the head-

stock to be tapped a fraction of a degree in the direc-

tion called for, then re-tighten the nuts. The “tap” can be

anything from a gentle slap of the hand to a rap with a

dead-blow mallet.

Repeat steps (7) through (10) until satised with the

tram, tightening the nuts as you go. This will likely call

for several iterations. There is no “right” tram; the ac-

ceptable dierence in side-to-side readings depends on

project specs. As a starting point, aim for ± 0.001” with a

sweep radius of 5 or 6 inches.

Tramming calls for patience! Expect to tighten

and re-check at least three times (simply tight-

ening the bolts can itself aect the tram).

A similar procedure may be used to check tram in the

Y-axis, front to back. The dierence here is that there is

that Y-axis tram is established in manufacture, and can

be adjusted only by these shop methods:

1. Shimming between the dovetailed Z-axis saddle

casting and the headstock itself. It is more likely

that the headstock is nodding forward rather than

leaning backward, so start with (say) a 2 mil shim in

line with the underside (central) headstock nut. This

is a temporary x that will need to be checked if the

headstock is tilted again.

2. Shimming between the underside of the column and

the main base casting. This is a long-term x. It is a

two-person procedure, requiring an engine hoist or

some other means of un-weighting the headstock

(see Section 1, Installation).

Figure 3-12 Shop-made indicator holder

Loading...

Loading...