13

PM-30MV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

Tramming is done by ne-tuning the headstock tilt angle. Tram

is typically checked by attaching a dial indicator to some form

of “sweepable” holder installed in the spindle, the aim being to

adjust tilt for the same reading on either side of the X axis. The

longer the radius arm, the greater the sensitivity.

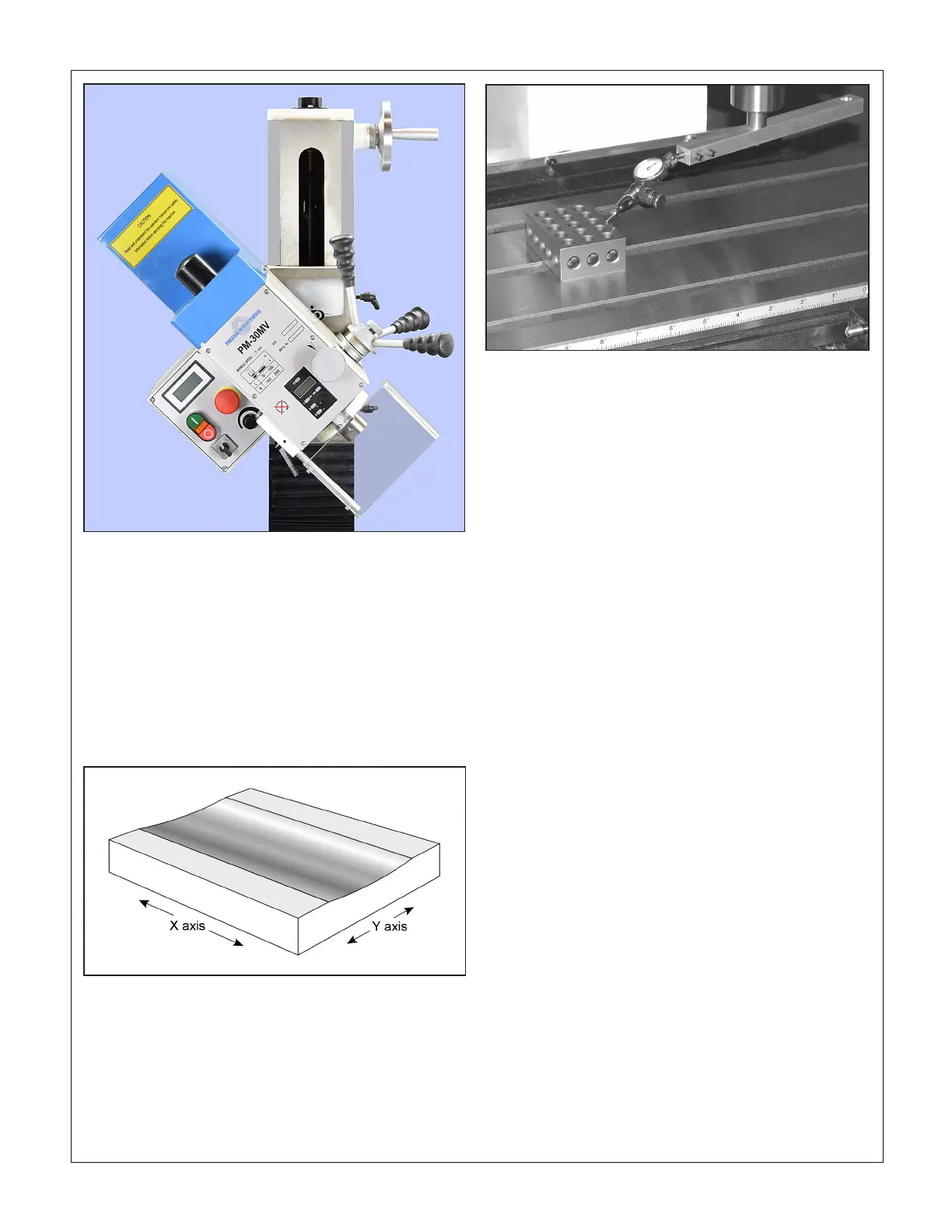

Figure 3-17 shows a typical shop-made holder; it has a thread-

ed arbor allowing the choice of two radius arms, 6 and 10 inch-

es measured from spindle centerline to indicator tip. A collet

is used to hold the arbor, in this example 5/8” diameter. The

dimensions are arbitrary, but note that the indicator must be

rmly attached, and the arm rock-solid relative to the indica-

tor spring force (which can be considerable on plunger-type

indicators).

A suggested procedure for establishing tram:

1. Disconnect power.

2. Install the dial indicator.

3. If the headstock has been tilted, reset it to the approximate

zero degree position on the tilt scale, then tighten the three

nuts enough to avoid unexpected headstock movement.

4. Remove the vise, if installed, and clean the table surface.

If there are noticeable grooves or dings, atten the surface

with a diamond lap or ne-grit stone.

5. Set a 1-2-3 block (or other precision-ground block) on the

table under the indicator probe.

6. Switch on the quill DRO.

7. Using the ne downfeed lower the spindle to give an indi-

cator reading of about half-scale.

8. Note the dial indicator and DRO readings, then back o

the ne downfeed at least a couple of turns to avoid colli-

sion when sweeping.

9. Reposition the 1-2-3 block to the opposite location on the

table.

10. Swing the indicator holder to the new location, then lower

the spindle – ne downfeed again – to give the same dial

indicator reading as in step (8).

If the headstock is perfectly trammed – highly unlikely at the

rst shot – the DRO reading should be as in step (8). If not,

loosen the nuts just enough to allow the headstock to be

tapped a fraction of a degree in the direction called for, then

re-tighten the nuts. The “tap” can be anything from a gentle

slap of the hand to a rap with a dead-blow mallet.

Repeat steps (7) through (10) until satised with the tram,

tightening the nuts as you go. This will likely call for several

iterations. There is no “right” tram; the acceptable dierence in

side-to-side readings depends on project specs. As a starting

point, aim for ± 0.001” with a sweep radius of 5 or 6 inches.

Figure 3-17 Shop-made indicator holder

Figure 3-16 Head tilt can aect surface atness

Figure 3-15 Headstock tilted 45 degrees counter-clockwise

TRAMMING THE HEADSTOCK

As shipped, the mill is set to zero tilt, squared accurately

enough for initial out of the box test drillings, etc. For more

demanding project work thereafter, the spindle needs to be

set at precisely 90 degrees relative to the table, in other words

trammed. “Out of tram” may show up as an oset of a few

thousandths between entry and exit of a deep hole, or as a

scalloped eect when surfacing a workpiece with a large-radi-

us y cutter, greatly exaggerated in Figure 3-16.

Loading...

Loading...