14

PM-30MV v3 2020-10 Copyright © 2020 Quality Machine Tools, LLC

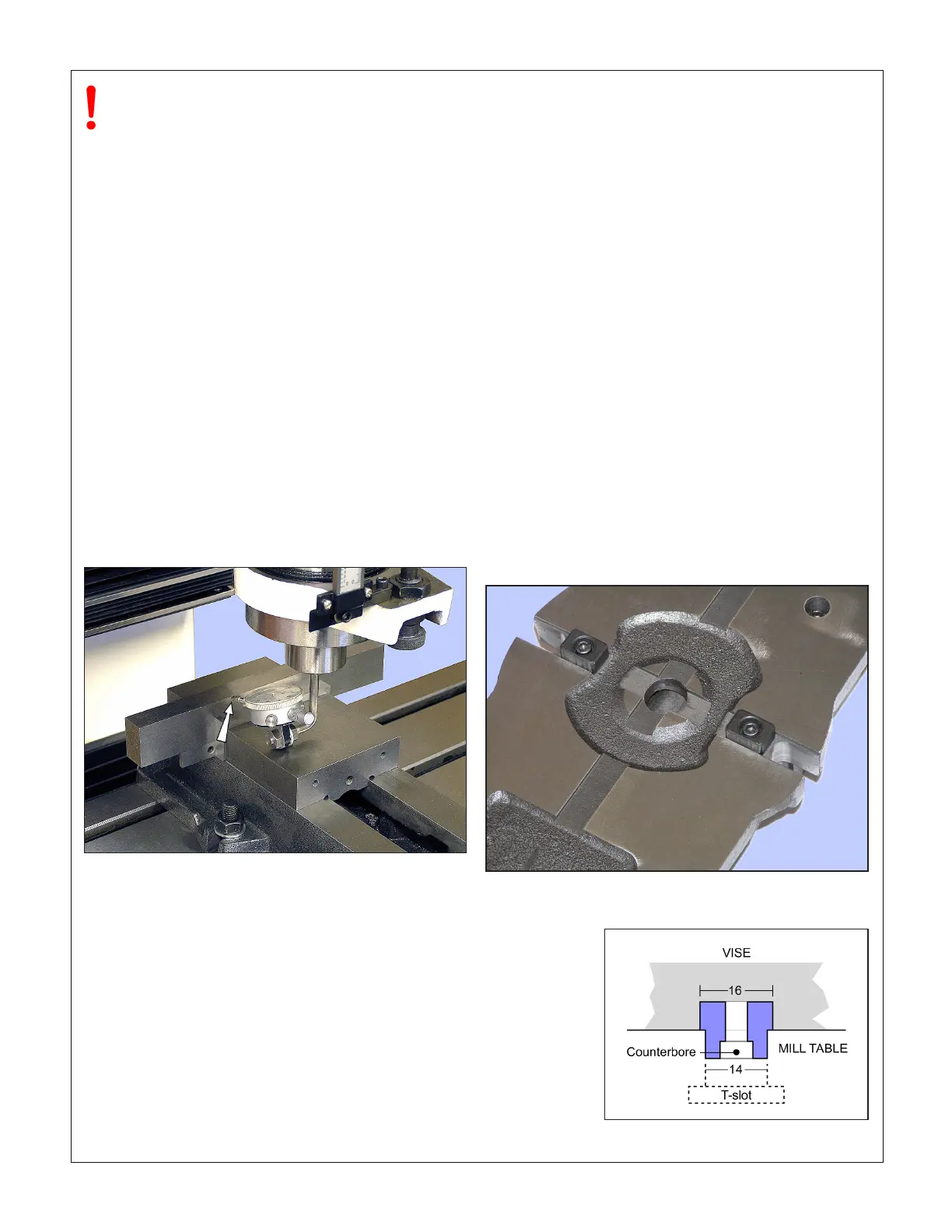

Figure 3-18 Indicating the vise

The tip of a standard dial indicator, arrowed, rides along the side face

of a ground reference bar (or the front face of the back jaw).

INSTALLING & INDICATING A VISE

For routine milling operations the workpiece is held in a preci-

sion vise. For the PM-30MV a 4” vise is most suitable. “Indicat-

ing” means checking the alignment of the xed (back) vise jaw

relative to the axis of table motion.

Tramming calls for patience! Expect to tighten and

re-check at least three times (simply tightening the

bolts can itself aect the tram).

Install the T-bolts and align the vise by eye. With one of the

clamp nuts snug, but not tight, tighten the other one just short

of fully-tight (but tight enough so the vise won’t budge without

a denite tap from a dead-blow mallet).

A typical setup for indicating is shown in Figure 3-18. Although

there is no spindle lock, you need to make sure that the spin-

dle does not rotate throughout the procedure. Set the indica-

tor tip against the upper edge of a precision reference bar or,

if not available, use the front face of the xed jaw of the vise

instead (check for dings, hone if necessary). Adjust the Y-axis

to pre-load the indicator to mid range at the tightly-clamped

side of the vise, then lock the Y-axis.

A procedure similar to the above may be used to check tram

in the Y-axis, front to back. The dierence here is that there

is that Y-axis tram is established in manufacture, and can be

adjusted only by these shop methods:

1. Shimming between the dovetailed Z-axis saddle casting

and the headstock itself. It is more likely that the head-

stock is nodding forward rather than leaning backward,

so start with (say) a 2 mil shim in line with the underside

(central) headstock nut. This is a temporary x that will

need to be checked if the headstock is tilted again.

2. Shimming between the underside of the column and the

main base casting. This is a long-term x. It is a two-per-

son procedure, requiring an engine hoist or some other

means of un-weighting the headstock (see Section 1, In-

stallation). As an alternative to shims, which do not pro-

vide a uniform bearing surface, consider injecting a met-

al-lled two-part polymer.

Note the indicator reading, then watch the indicator as you tra-

verse the table slowly toward the loosely clamped side. (Also

watch for any sign of spindle rotation.) Ideally, there should

be no discrepancy between the indicator readings at the two

ends — unlikely at the rst attempt. Return the table to the

starting point, then repeat the process, tapping the vise in as

you go. Repeat the process as often as necessary for the de-

sired accuracy, progressively tightening the “looser” nut. Now

fully tighten both nuts, and re-check again (tightening a nut

can itself introduce signicant error). An established routine

like this – tight to loose – can save a lot of time.

Most users aim for an end-to-end dierence of not more than

± 0.001” over the width of the vise jaw.

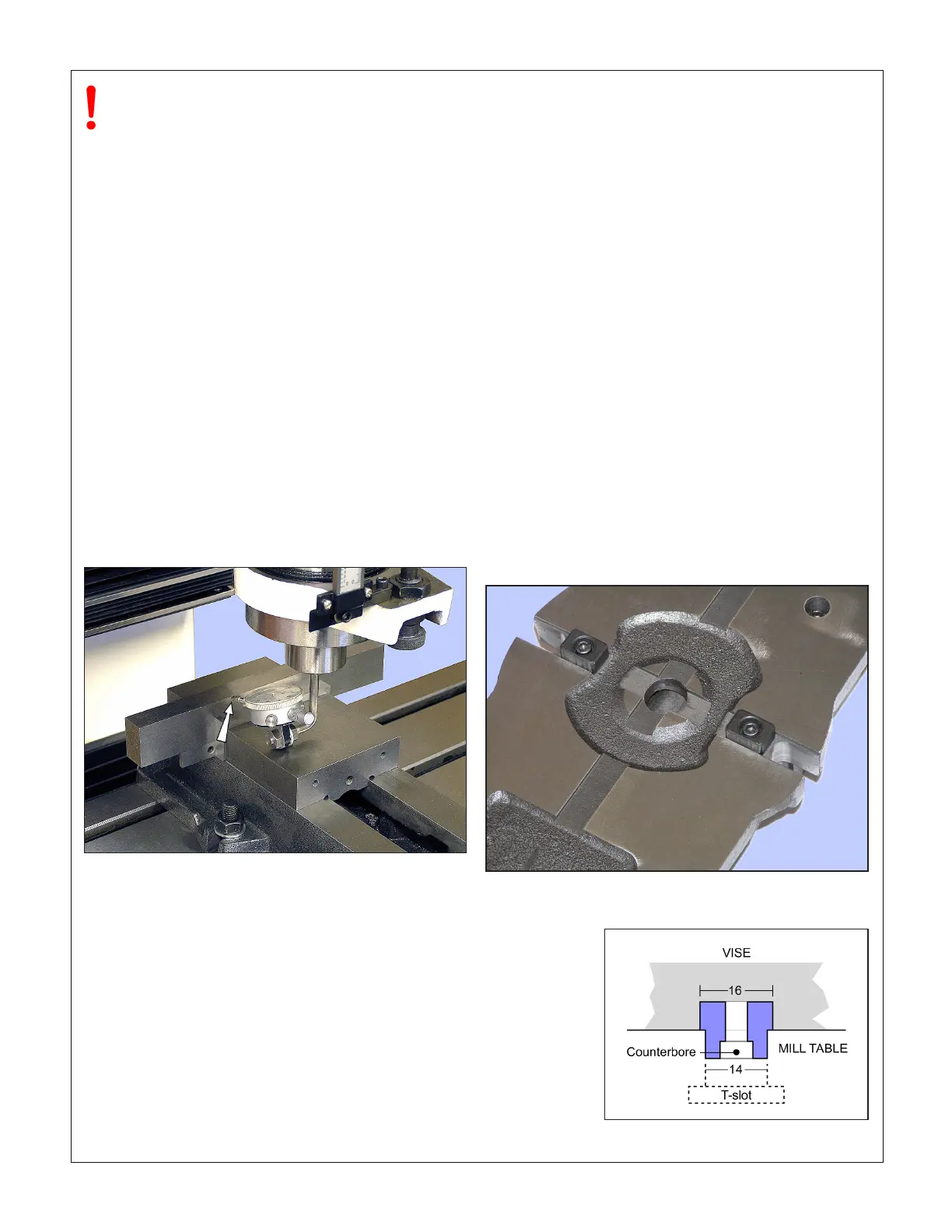

VISE KEYS

Most precision vises come with key slots on the underside ma-

chined exactly parallel to the xed jaw. Keys installed in the

slots can be a great time saver, Figure 3-19. Properly installed

they allow the vise to be removed and replaced routinely, ac-

curately enough for general machining without the need for

indicating every time.

Most 4” vises have either 14 mm or 16 mm slots, calling for

shop-made adapter keys as Figure 3-20. It is well worth the

eort to make these precisely. Aim for a snug t in both vise

and table, but not so tight that it takes more than reasonable

eort to lift the vise clear. Case hardening is recommended,

with nal tting using a ne stone or diamond stone.

Figure 3-20 Shop-made vise key

Dimensions in millimeters

Figure 3-19 Vise keys installed on X-axis

On most vises the keys can also be installed on the long axis.

This vise came with 14 mm slots,

so the keys have parallel sides

Loading...

Loading...