01

02

03

04

05

06

07

08

09

13

14

12

11

10

15

16

17

18

19

20

21

22

Oil

11

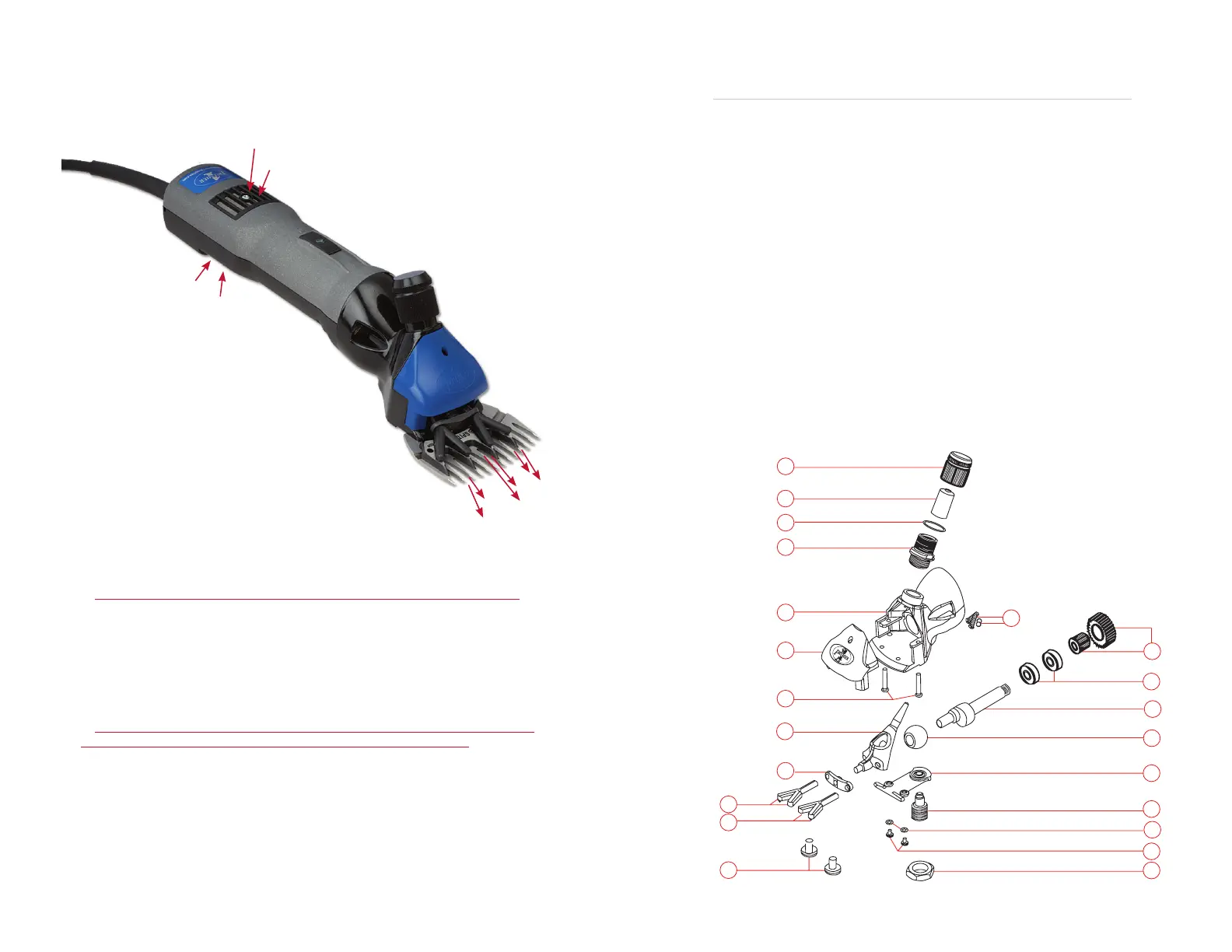

Item No. Part No. Description

01 82900401 1 - Tension nut

02 82900402 1 - Sliding sleeve

03 82900403 1 - Tension lock spring

04 82900404 1 - Lid bushing

05 82900405 1 - Shearing head (without accessories)

06 82900406 1 - Plastic head cover

07 82900407 1 - Head cover screw (2 required)

08 82900408 1 - Fork guide bracket

09 82900409 1 - Fork plate

10 82900410 1 - Fork fi nger (right)

11 82900411 1 - Fork fi nger (left)

12 82900412 1 - Comb screw

13 82900413 1 - Fulcrum lock nut

14 82900414 1 - Countersunk head screw

15 82900415 1 - Toothed washer

16 82900416 1 - Fulcrum post screw

17 82900417 1 - Tension spring plate

18 82900418 1 - Crank roller

19 82900419 1 - Crank spindle shaft

20 82900420 1 - Bearing

21 82900422 1 - Spindle hub with fi bergear

22 89600610 2 - Head screws and 2 washers (sold as a set)

4000s Shearing Head Parts

Premier recommends returning units

back to us for internal motor repairs.

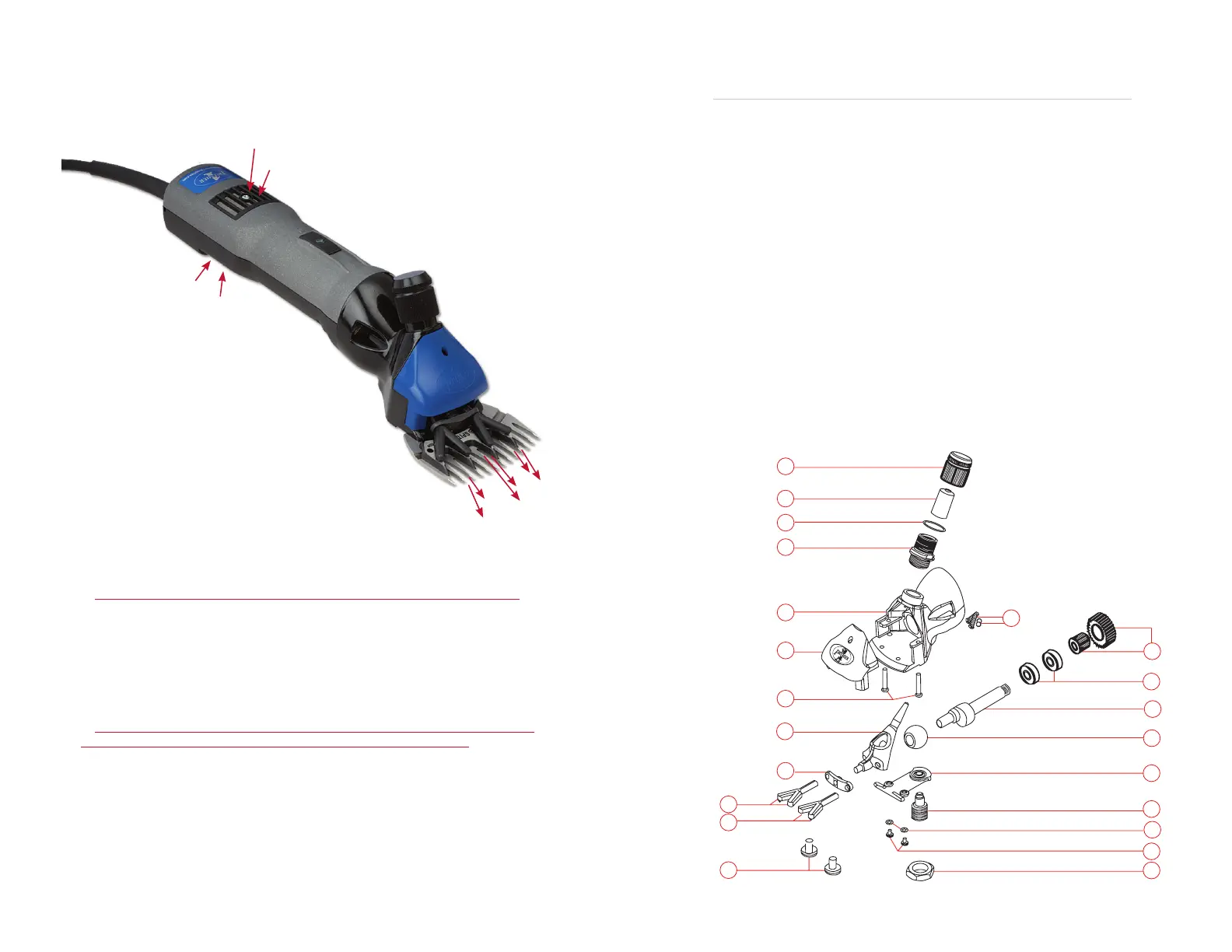

Outgoing Air

10

Important Warnings

Ventilated Motors:

Do not attempt to connect this motor to any Premier shear head or clipper head

acquired by yourself or your dealer before June 20, 2003.

If you do the motor will overheat and destroy the internal windings.

Why? The air from this motor is driven forward and out through the heads. This is a

new feature that results in cooler operating temperatures (up to 20 degrees less) of heads,

blades, combs and cutters. However, for this to occur the shear head or clipper head is

designed to enable the air to exit through the head. Older clipper heads can easily be

changed to allow this by knocking out the 2 black plastic kidney-shaped plugs on either

side of the drive shaft.

Shear heads supplied before June 20, 2003 will need to be sent back to

Premier for retro tting before they can be tted to this motor.

Shearing Machine Warning:

Do not switch this machine on unless the 4 point cutter is properly in place and

tensioned against the comb. As a guide, screw the tension knob down against the cutter

until resistance is felt, making sure that the fork fi ngers are tight against the cutter. Then

screw it another 1/2 turn further before switching the machine on.

Incoming

Air

Air Filter

Air Filter

Incoming Air

Loading...

Loading...