PREMIER E SERIES DUAL CAPACITY INSTALLATION AND MAINTENANCE MANUAL

23

4) If control responds improperly:

• Ensure that component being controlled is functioning (Compressor, Blower, Reversing

valve, etc.).

• Ensure that wiring from control to the component is functioning (use the diagnostic

outputs mode).

• If steps above check properly, replace unit control.

NOTE:

Refer to the wiring schematic on pages 14-15 for additional information.

REFRIGERANT SYSTEM

NOTE:

Verify that air and water flow rates are at proper levels before servicing the

refrigerant circuit.

To maintain sealed circuit integrity, do not install service gauges unless unit operation appears

abnormal (refer to the unit operating pressures and temperatures table below). If superheat and

subcooling are outside recommended ranges, an adjustment to the refrigerant charge may

be necessary.

OBTAINING PARTS

When contacting WFI for service or replacement parts, refer to the model number and serial

number of the unit as stamped on the serial plate attached to the unit. If replacement parts are

required, mention the date of installation of the unit and the date of failure, along with an explanation

of the malfunctions and a description of the replacement parts required.

IN-WARRANTY MATERIAL RETURN

Material may not be returned except by permission of authorized WFI warranty personnel. Contact

your local distributor or the WFI warranty department for warranty return authorization and assistance.

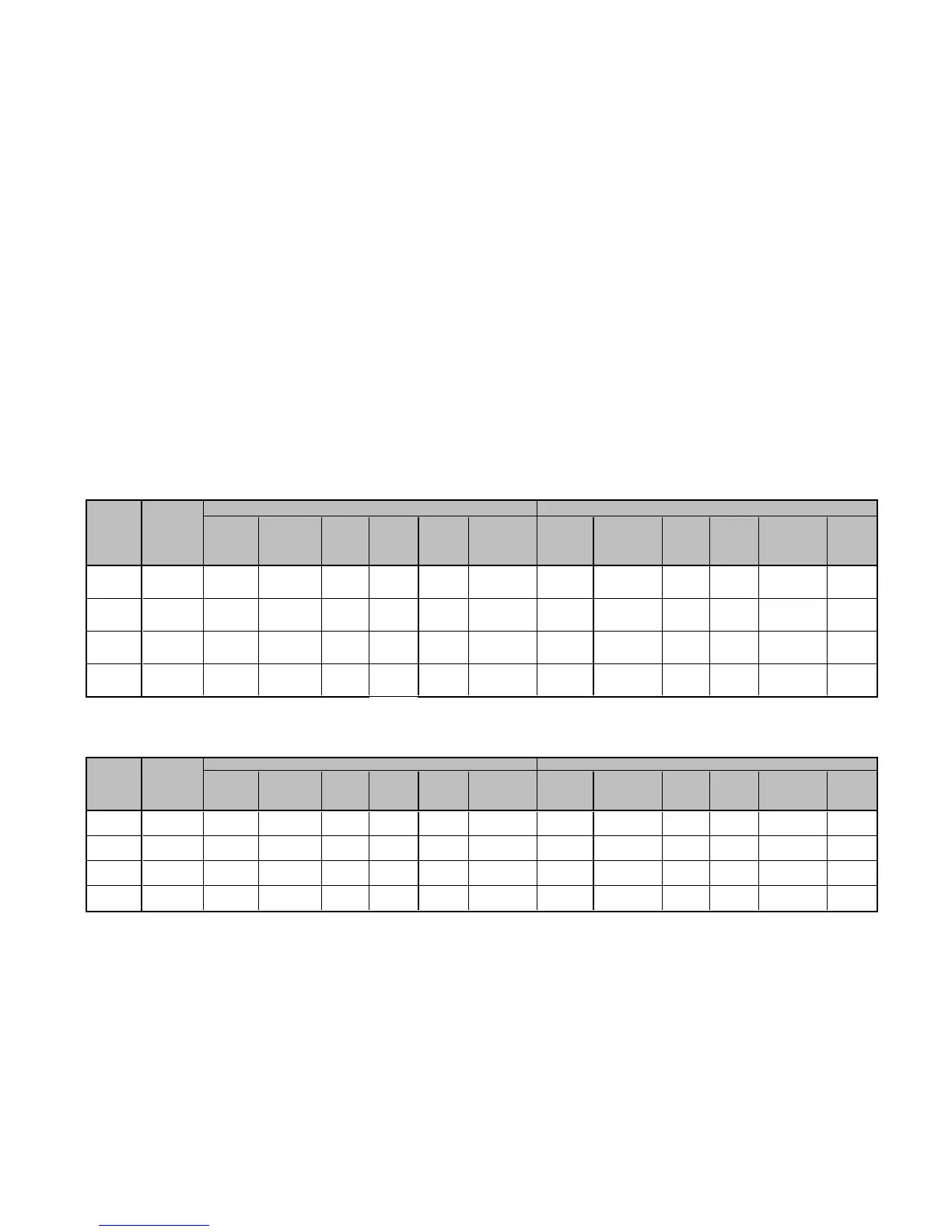

Unit Operating

Pressures*

Two cylinder operation

Cooling - No Desuperheater** Heating - No Desuperheater

Entering Water Suction Discharge Water Air Suction Discharge* Water Air

Water Flow Pressure Pressure Super- Sub- Temp Temp Pressure Pressure Super- Sub- Temp Temp

Temp °F GPM/TON PSIG PSIG heat cooling Rise °F Drop °F DB PSIG PSIG heat cooling Drop °F DB Rise °F

30 1.5 - - - - - - 64-72 285-320 11-16 13-19 5-7 15-21

3.0 - - - - - - 68-76 290-325 11-16 13-19 3-5 17-23

50 1.5 117-123 225-240 14-20 10-16 20-24 21-25 91-104 320-355 9-14 18-24 6-8 22-28

3.0 115-121 195-215 14-20 10-16 10-14 21-25 95-108 325-360 9-14 18-24 4-6 24-30

70 1.5 124-132 290-310 12-16 10-16 19-23 20-24 131-146 365-400 8-13 18-24 9-11 30-36

3.0 122-130 260-280 12-16 10-16 9-13 20-24 135-150 370-405 8-13 18-24 7-9 32-38

90 1.5 132-140 380-410 10-14 10-16 18-22 18-22 - - - - - -

3.0 130-138 350-380 10-14 10-16 8-12 18-22 - - - - - -

*Deduct 10# psig for E036

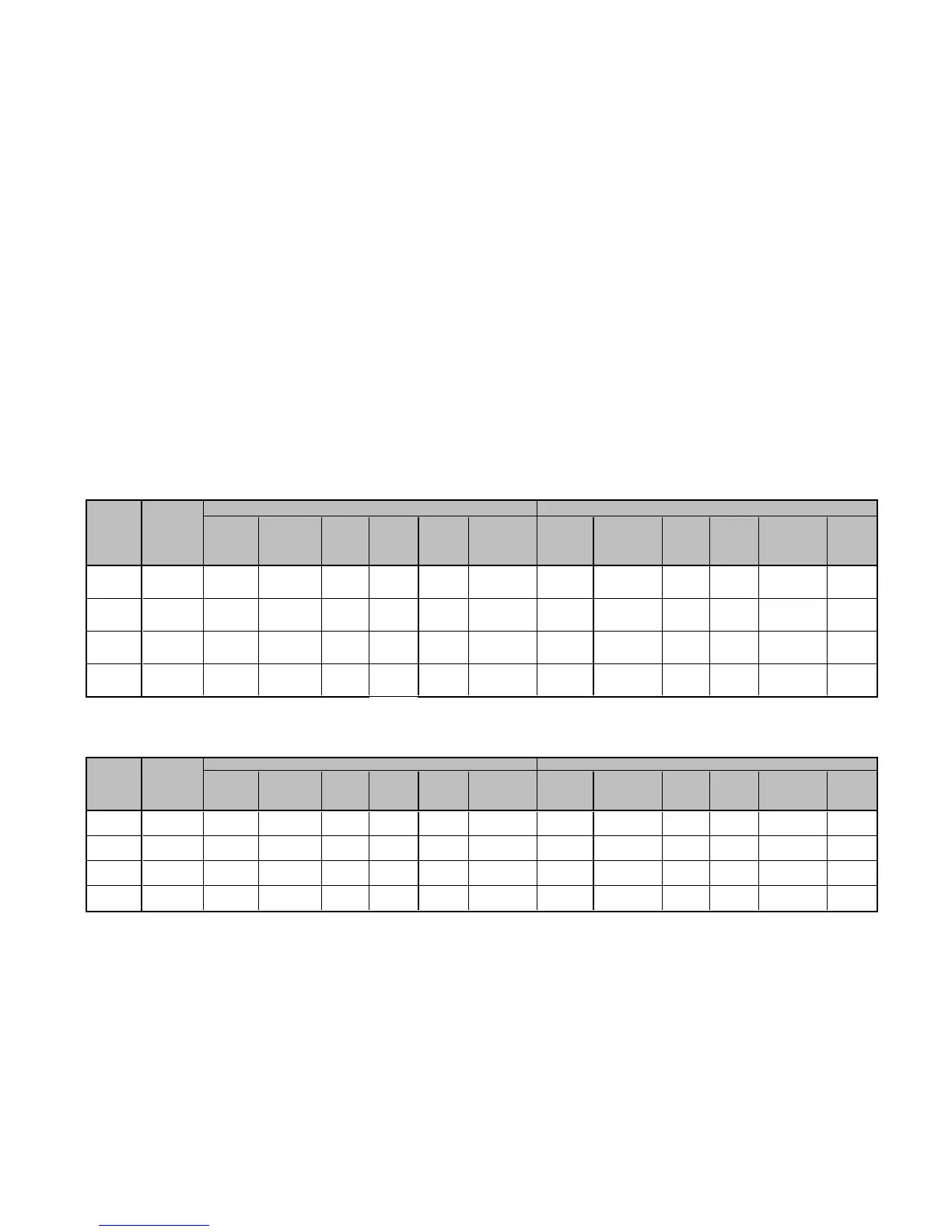

One cylinder operation

Cooling - No Desuperheater** Heating - No Desuperheater

Entering Water Suction Discharge Water Air Suction Discharge* Water Air

Water Flow Pressure Pressure Super- Sub- Temp Temp Pressure Pressure Super- Sub- Temp Temp

Temp °F GPM/TON PSIG PSIG heat cooling Rise °F Drop °F DB PSIG PSIG heat cooling Drop °F DB Rise °F

30 1.5 - - - - - - 76-84 269-282 8-12 2-8 4-6 12-16

3.0 - - - - - - 80-88 274-287 8-12 2-8 2-4 14-18

50 1.5 134-144 195-203 14-20 12-18 21-25 21-25 112-120 295-315 8-12 2-10 6-8 18-22

3.0 132-142 180-186 14-20 12-18 10-15 21-25 116-124 300-320 8-12 2-10 4-6 20-24

70 1.5 142-150 257-264 12-16 12-18 20-24 20-24 156-166 325-350 8-12 4-12 7-9 26-30

3.0 140-148 242-249 12-16 12-18 9-13 20-24 160-170 330-355 8-12 4-12 5-7 28-32

90 1.5 148-155 335-345 10-14 12-18 18-22 18-22 - - - - - -

3.0 146-153 320-330 10-14 12-18 8-12 18-22 - - - - - -

*Deduct 25# psig for E036

Replacement

Procedures

Loading...

Loading...