8

PREMIER E SERIES DUAL CAPACITY INSTALLATION AND MAINTENANCE MANUAL

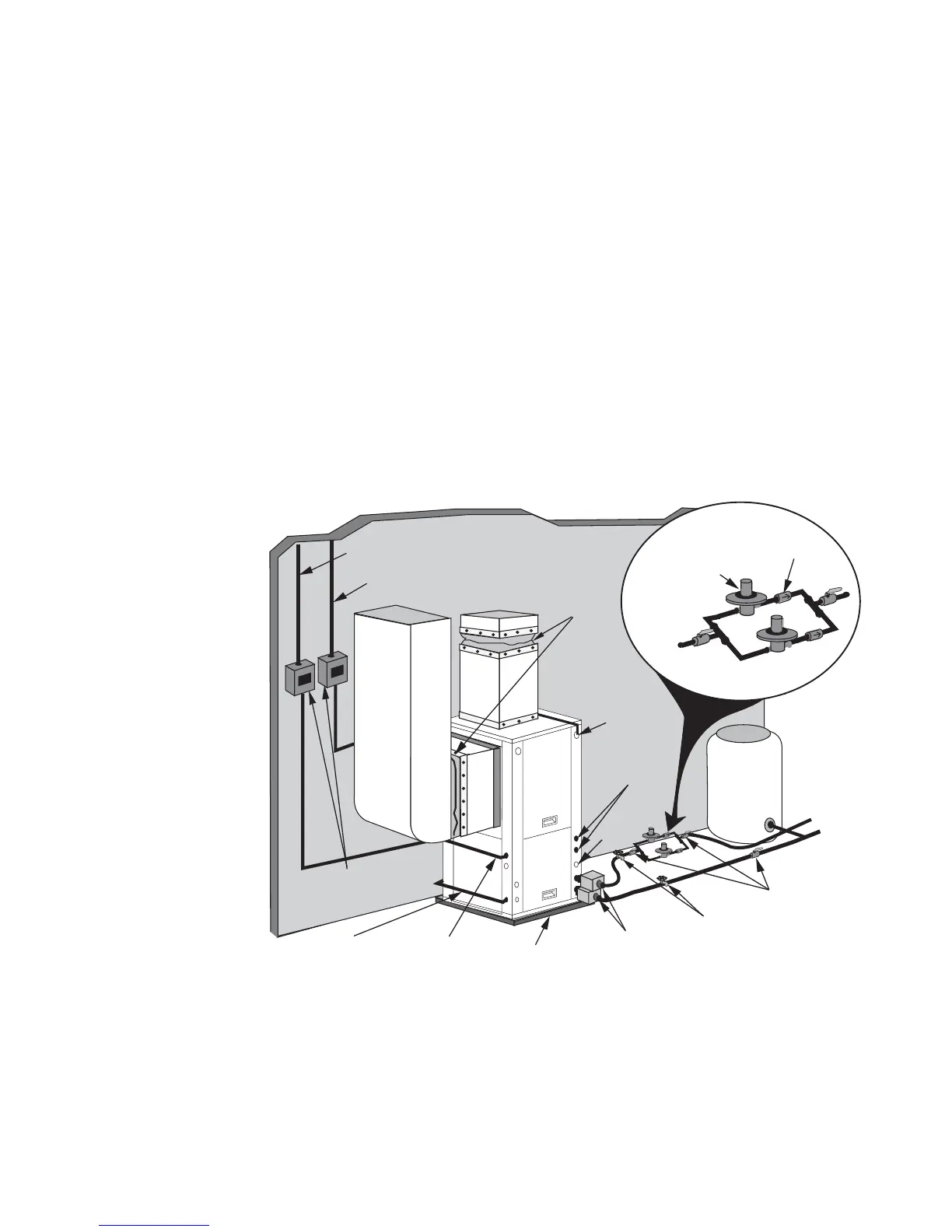

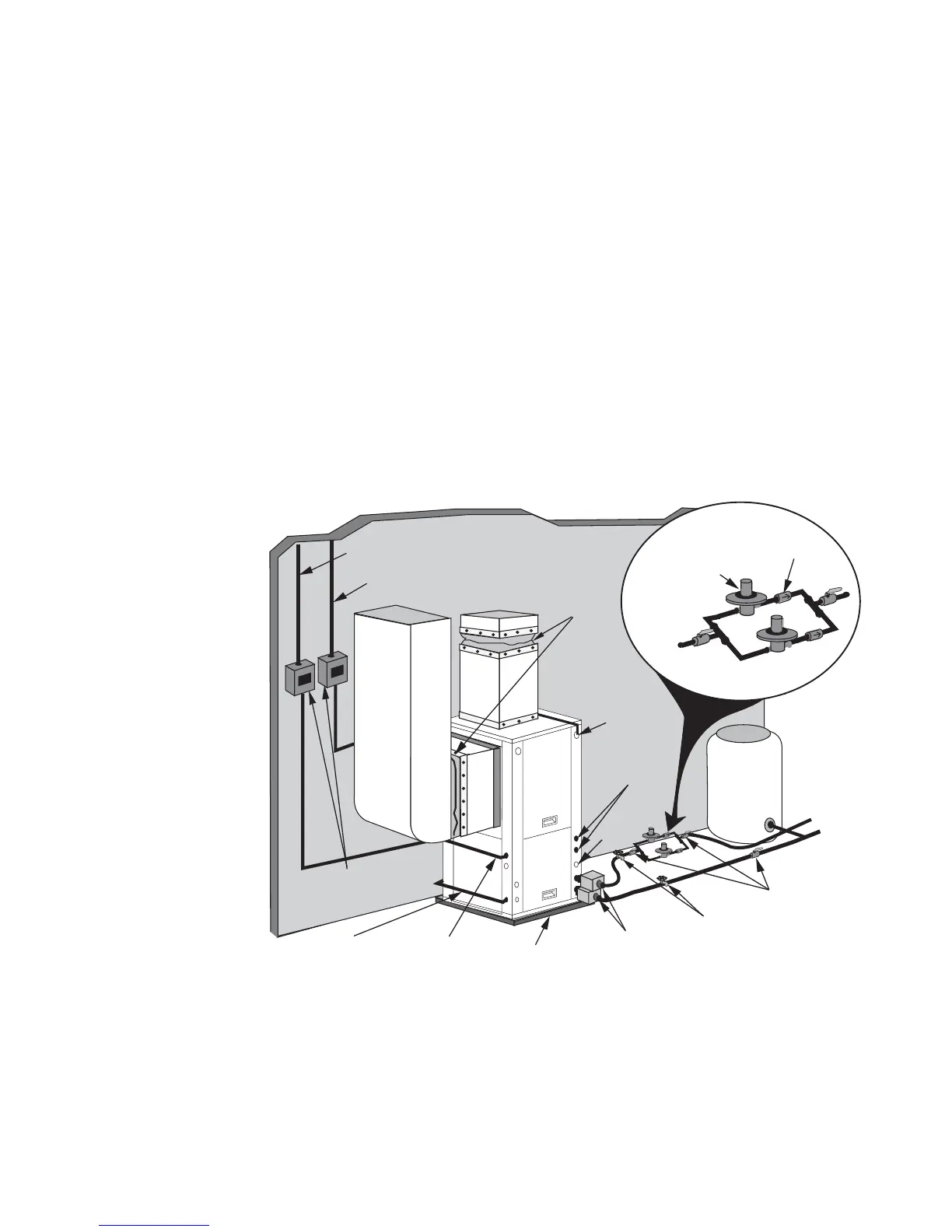

OPEN LOOP SYSTEMS

NOTE:

For open loop/groundwater systems or systems that do not contain an antifreeze solution,

set SW2-Switch #2 to the “WELL” position,

(See schematic on pages 14 and 15).

Typical open loop piping is shown in Figure 8. Always maintain water pressure in the heat

exchanger by placing water control valves at the outlet of the unit to prevent mineral precipitation.

Use a closed, bladder-type expansion tank to minimize mineral formation due to air exposure. Insure

proper water flow through the unit by checking pressure drop across the heat exchanger and

comparing it to the figures in Table 2 on page 21. Usually 1.5-2 gpm of flow per ton of cooling

capacity is recommended in open loop applications. In dual capacity units, stage 1 is half of the total

tonnage. Therefore, on a E048, the stage 1 solenoid should flow 3-6 gpm and stage 1 & 2 together

should flow 6-9 gpm.

Discharge water from the unit is not contaminated in any manner and can be disposed of in

various ways, depending on local building codes, i.e. recharge well, storm sewer, drain field, adjacent

stream or pond, etc. Most local codes forbid the use of sanitary sewer for disposal. Consult your

local building and zoning department to assure compliance in your area.

Open Loop

Groundwater

Systems

Figure 8 - Open System: Groundwater Application

Flexible

Duct Collar

Vibration

Absorbing Pad

P/T Plugs

Drain

Desuperheater

Connections

Auxiliary

Heater

Knockout

Low Voltage

to Thermostat

and Valve

Unit Supply

Auxiliary Heat Supply

Water Out

Water In

Shut Off

Valves

Boiler Drains

For HX Flushing

Solenoid Valve

(two should be used

in parallel.)

Flow

Regulator

Disconnects

(If Applicable)

Unit

Power

Loading...

Loading...