5

SAFETY

How a plasma cutter works

Basic plasma cutters use electricity to superheat air into plasma (the 4th state of

matter), which is then blown through the metal to be cut. Plasma cutters require

a compressed air supply and AC power to operate.

Operation

1. When the trigger is squeezed, DC current ows through the torch lead into the

nozzle.

2. Next, compressed air ows through the torch head, through the air diuser that

spirals the air ow around the electrode and through the hole of the cutting

nozzle.

3. A xed gap is established between the electrode and the nozzle. (The power

supply increases voltage in order to maintain a constant current through the

joint.) Electrons arc across the gap, ionizing and super heating the air creating a

plasma stream.

4. Finally, the regulated DC current is switched so that it no longer ows to the

nozzle but instead ows from the electrode to the work piece. Current and airow

continue until cutting is stopped.

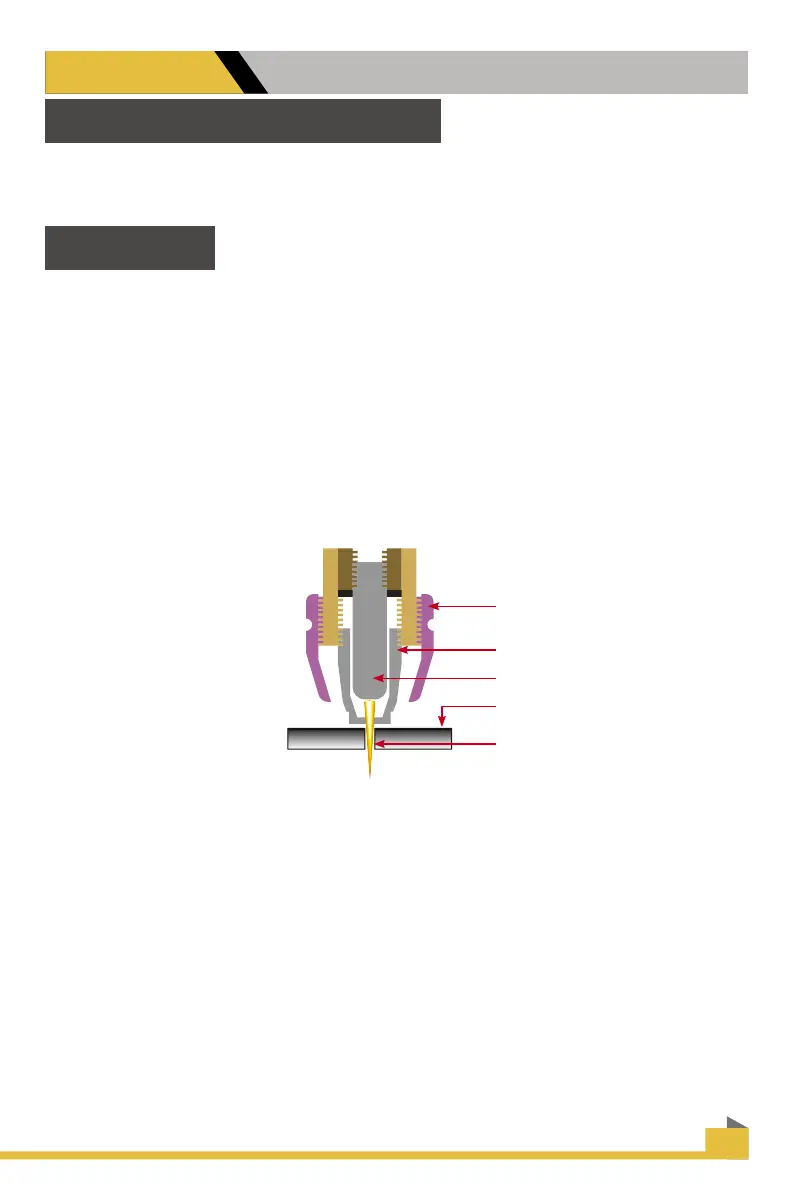

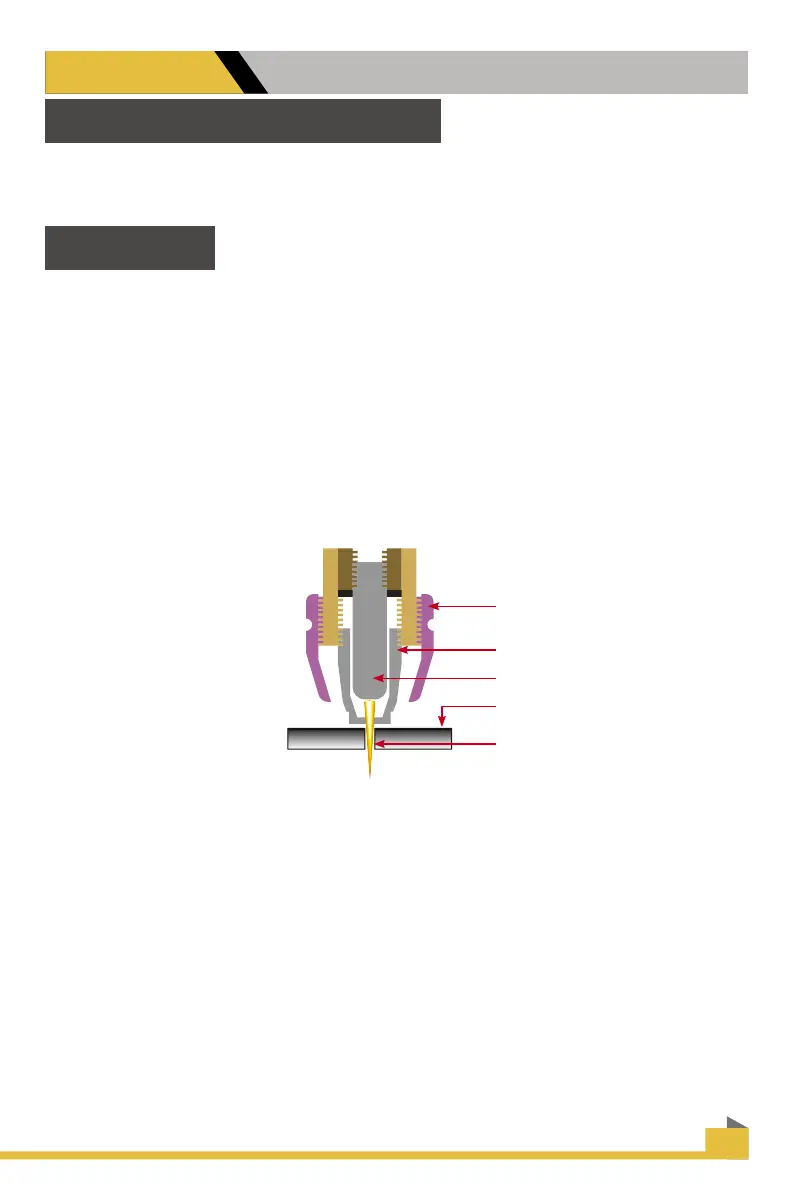

Shield Cup

Nozzle

Electrode

Plasma Stream

Steel

Notes:

The nozzle and electrode require periodic replacement. The electrode has an insert

of tough high conductive material such as hafnium and cerium. This insert erodes

with use, also the nozzle orice will erode with use.

Quality of the air used is paramount to longer life of electrodes and nozzles, in

short clean dry air gives longer parts life, the cleaner and dryer the better. We

recommend use of a Plasma Air Filter.

Loading...

Loading...