16

LAYOUTOPERATION

1.place and hold the torch vertical At the

edge of the plate.

2. Pull the trigger to energise the pilot arc.

The cutting arc will start when the nozzle

is moved closer to the edge of the work

piece. When the cutting arc has cut

through the edge of the plate start moving

evenly in the direction you wish to cut.

3. Correct amperage and travel speed arc

importand and relevant to material

thickness and are correct when sparks

are exiting from the work piece. if sparks

are spraying up from the work piece there

is insucient amps selected or the travel

speed is too fast.

4. To nish the cutting release the torch

switch. The air ow will continue for 20

seconds to cool the torch head.

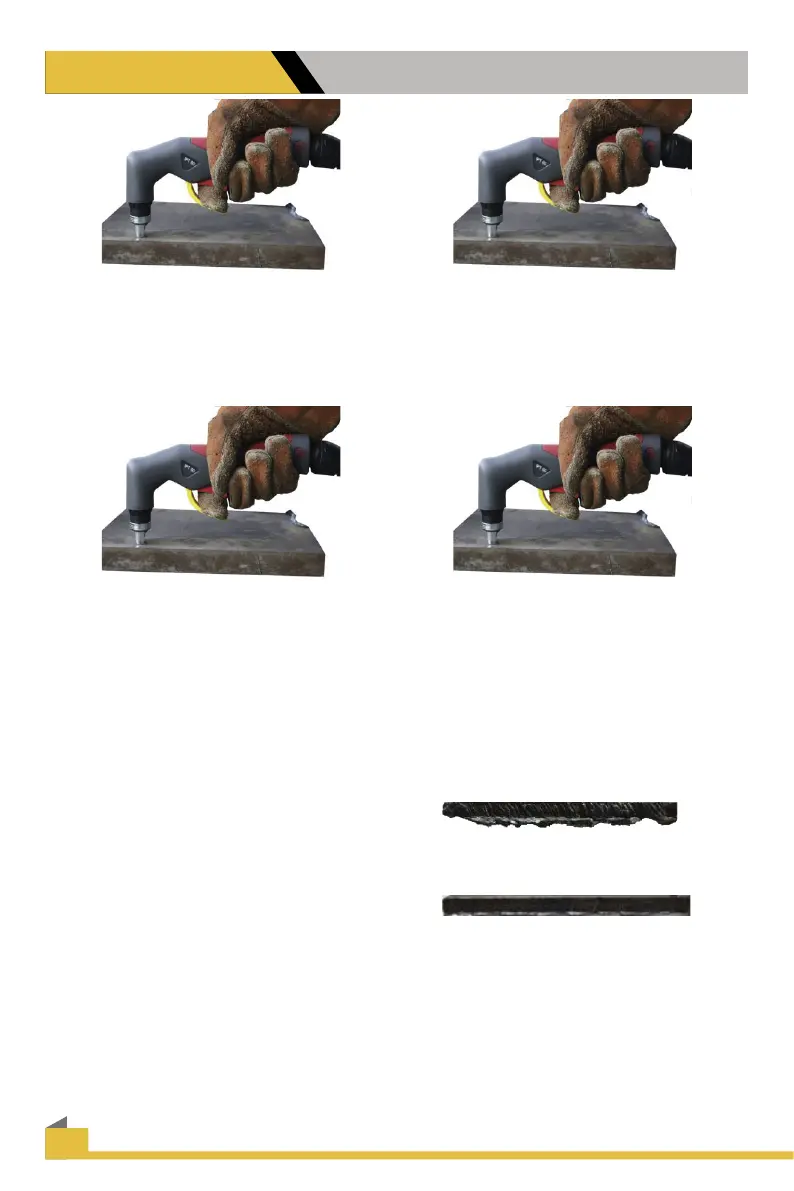

Cut Quality

A clean cut depend on several factors: Poor quality cut

● amperage

● travel speed

● tip height & position

● tip and electrode quality Good quality cut

● air pressure and quality

● technique

The best quality cut will be produced when all these variables are set correctly

for the material thickness and type of material being cut.

Loading...

Loading...