Assembly (Continued)

FOR MODELS KFA50PF AND

KFA75PF ONLY

FOR MODELS KFA125PF, KFA170PF

AND KFA210PF ONLY

TOOLS REQUIRED

5

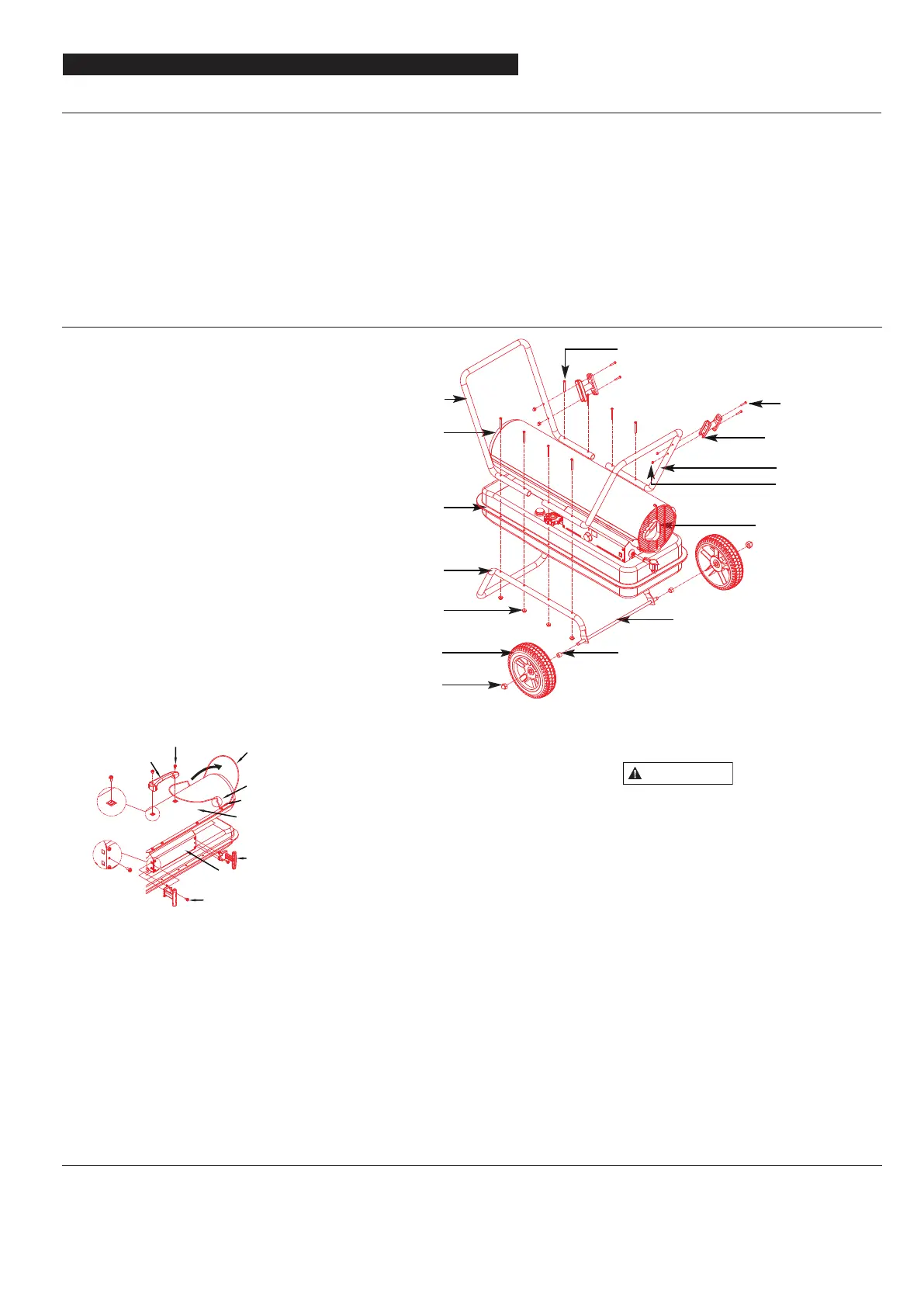

Figure 7 – Handle and Cord Wrap

Installation KFA50PF and

KFA75PF only

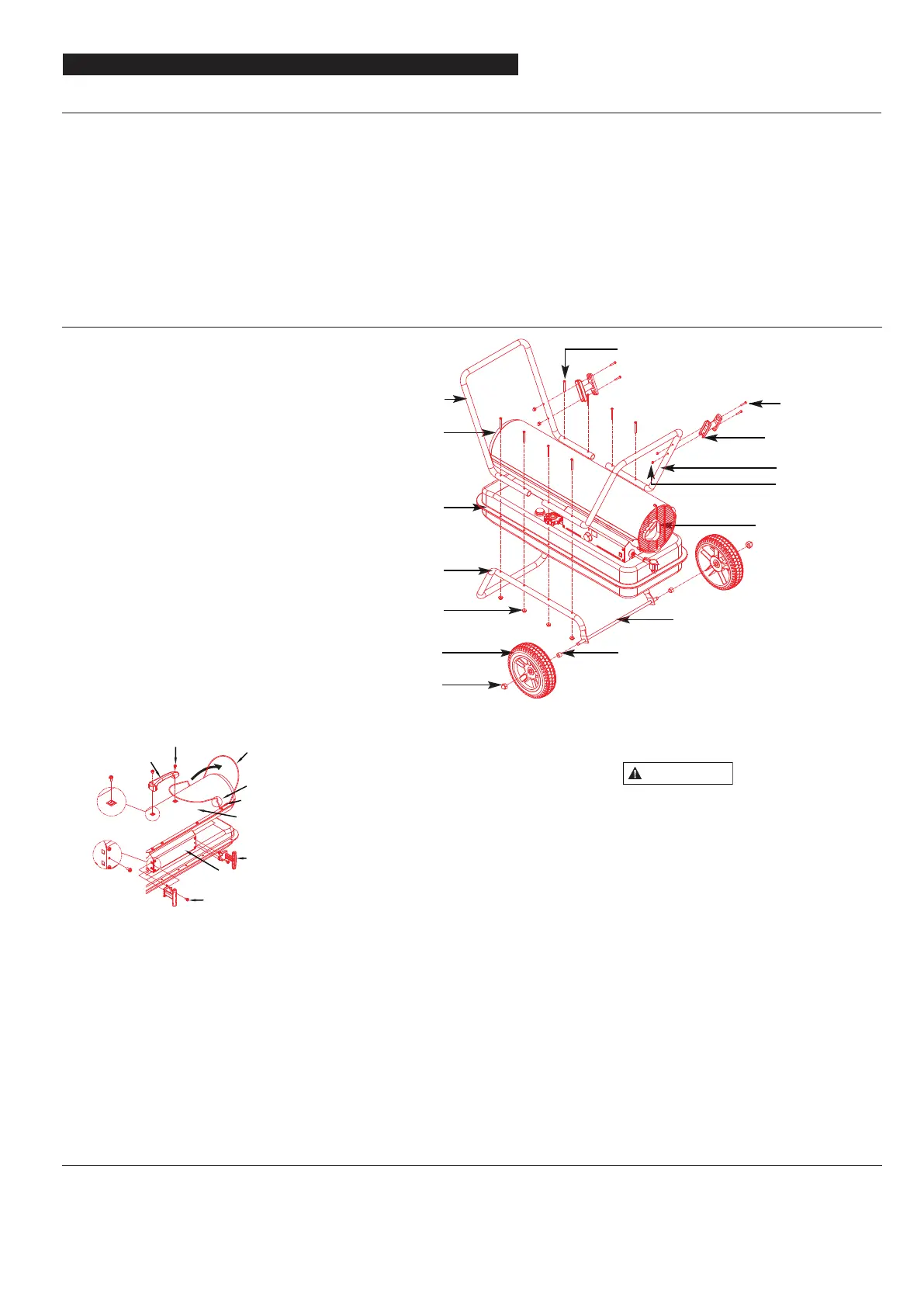

Figure 8 – Models KFA125PF, KFA170PF and KFA210PF Assembly

- Medium Phillips Screwdriver.

- 3/4 inch socket or adjustable wrench

Assembling Handle & Wheel and

Cord Wrap

1. Slide threaded axle through the rear

sectioon of the wheel support frame.

ProFitter

TM

Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

2. Slide one axle bushing on to each side

of the axle. Slide one wheel on to each

side of the axle. Attach one cap nut on

to each side of the threaded axle and

tighten well.

3. Place heater on wheel support frame.

Align the holes on fuel tank flange

with holes on wheel support frame.

4. Position the Handles on top of fuel

tank flange.

Insert screws through handles, fuel

tank flange and wheel support frames

as shown in Figure 8 and attach nut

finger tight after each screw is inserted.

5. Align the hole on the handles with the

mounting hole on the Cord Wrap.

Insert Scre

ws through Cord Wrap,

handles and attach nut finger tight

after each screw is inserted.

6. After all screws are inserted, tighten

nuts firmly.

Do not operate

heater without

support frame fully assembled to tank.

FUELS

For optimal performance of this heater,

it is strongly suggested that 1-K kero -

sene be used. 1-K kerosene has been

refined to virtually eliminate contami -

nants, such as sulfur, which can cause a

rotten egg odor during the operation

of the heater. However, #1/#2 diesel/fuel

oil, JET A or JP-8 fuels may also be used if

1-K kerosene is not available. Be advised

that these fuels do not burn as clean as

1-k kerosene, and care should be taken

to provide more fresh air ventilation to

accommodate any added contaminants

CAUTION

Front Handle

Hot Air Outlet

Wheel

Cap Nut L

Cap Nut S

Fuel Tank Flange

Nut

Wheel Support

Frame

Flange Screw

Cord Wrap

Screw

Rear Handle

Air Inlet

Threaded Axle

Wheel Bushing

TOOLS REQUIRED

- Medium Phillips screwdriver.

1. Lift front guard for arrow direction

and make sure that guard’s wedged

portion fits into the slit hole on the

upper housing.

2. Remove the pre-assembled screws on

the shell upper and side cover.

3. Align the holes in upper housing

withtwo mounting holes on the

handle asshown in Figure 7.

4. Secure handle with the screws

removed.

5. Insert cord wrap into the rectangle

holes on the supporter and align the

hole on the cord wrap with the

mounting hole on the side cover as

shown in Figure 7.

6. Secure cord wrap with the screws

removed.

Handle

Screw

Front Guard

Wedged

Slit Hole

Side Cover

Cord Wrap

Screw

Shell Upper

Remove Screws

Remove Screws

Portion

Loading...

Loading...