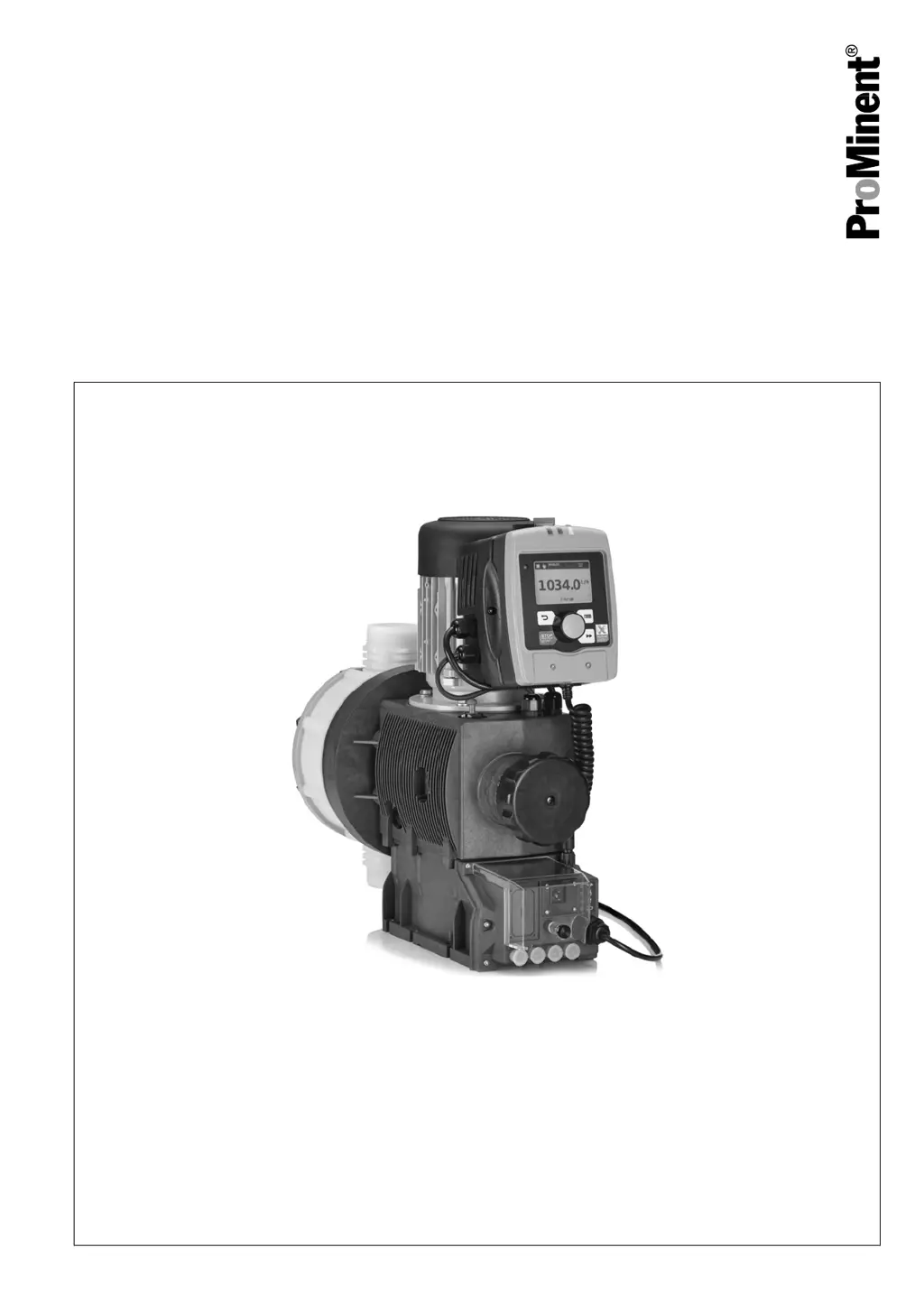

What to do if ProMinent Water Pump does not prime?

- JjohnsonmichaelAug 2, 2025

If your ProMinent Water Pump isn't priming even with a full stroke and after bleeding, it could be due to minor crystalline deposits on the ball seat from the valves drying out. Try taking the suction hose out of the storage tank and thoroughly flushing out the liquid end. If the issue persists, heavy crystalline deposits might be the cause. In that case, dismantle the valves and clean them.