46

Troubleshoooting

| 46 | Version 1.0

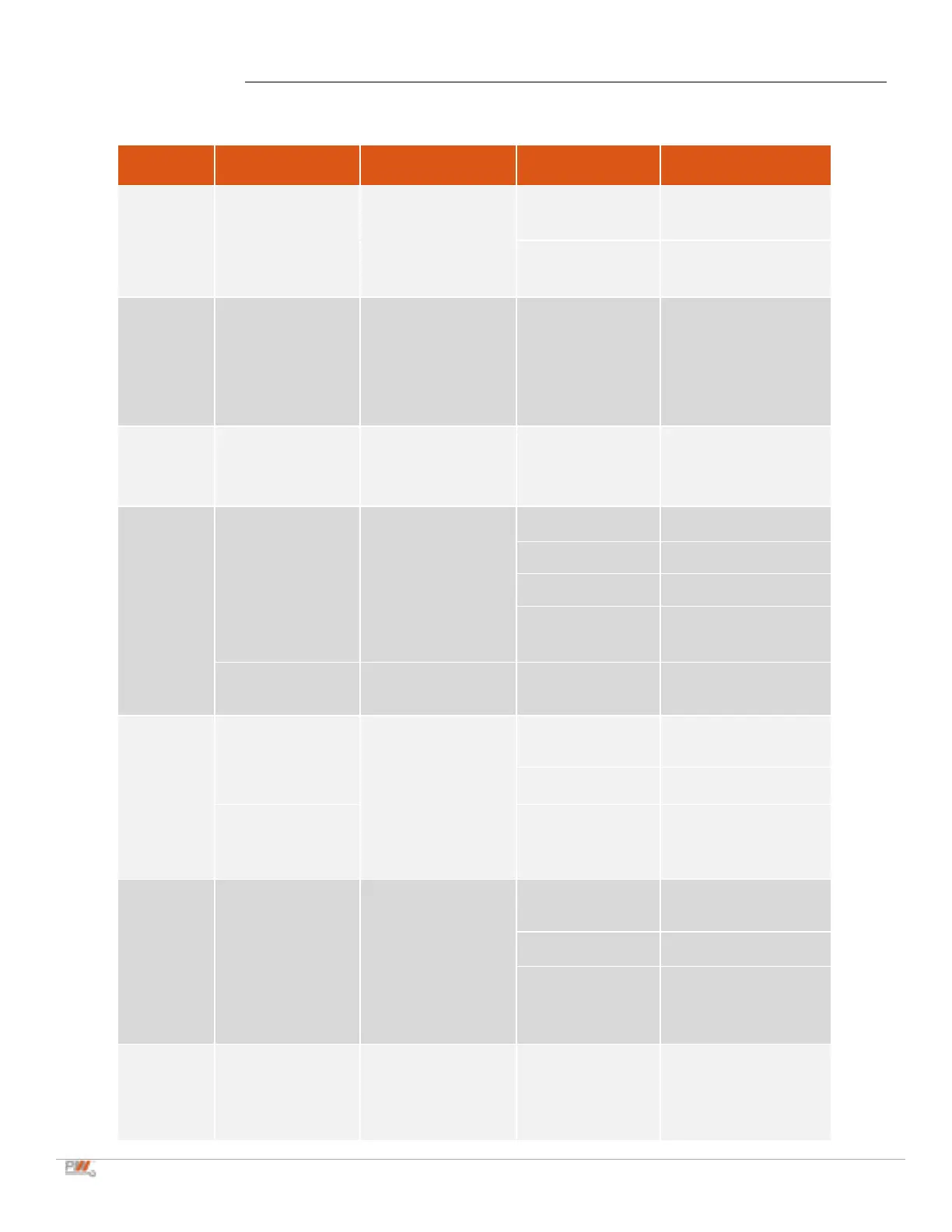

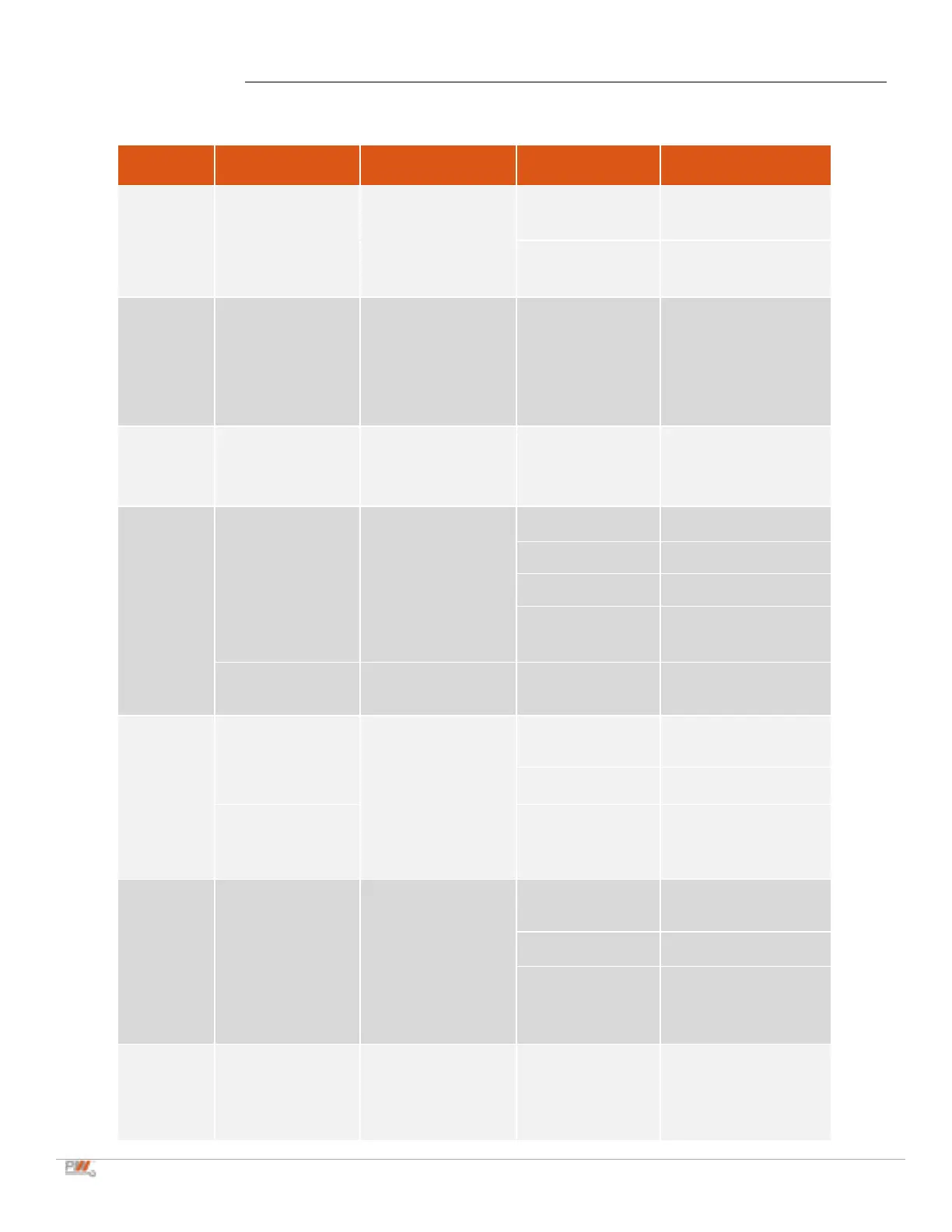

Condition

Reason Action Cause Correction

Chain twist

Bottom hook upturned Reset hook

Bottom hook rotation

during usage

Check hook state before

operation

Chain twist in machinery

body

Reassemble chain guide

and load chain

Improper assembly Ensure proper assembly

Limit switch

suddenly acti-

vated

in decline

Chain twist or knot in

chain bag

Conrm chain bag capac-

ity (chain bag nameplate)

replace with larger one if

capacity insucient

Chain bag inadequate

capacity

Conrm lifting height and

chain bag capacity

Crackling sound Chain damage

Measure wear of chain

link diameter. Replace if

reaching wear limit

Long-term operation

with insucient

lubrication

Apply grease lubricant

regularly

Irregular sound

from springs

(cracking

sound)

Wear of link part

Measure diameter on

wear of chain, and replace

when at wear limit

Excessive operation Avoid excessive operation

Overload Use under rated load

Incline pull Ensure proper pull direction

Wear of load pulley and

empty pulley

Refer to load pulley and

empty pulley

Extension of pitch

Measure pitch and replace

when exceeding limit

Overload Use under rated load

Irregular

sound

Damage or deformation

on chain surface

Replace when obvious

damage and deformation

occur

Use under transition

situation

Use under models with

multiple chain

Chain used improperly Ensure proper assembly

Mark on chain surface

Damaged by other

equipment

Monitor surrounding envi-

ronment throughout usage

to avoid collisions

Discoloration Rust, corrosion

Apply lubricants and

replace when obvious rust

and corrosion occurs

Lubricant exhausted

Apply lubricating oil regu-

larly

Exposure to water Use in dry places

Inuenced by seawater

or chemical agent

Inform us if used in special

circumstances to safeguard

range

Load chain

fractured

Reaching service life

Check chain, replace if

diering from benchmark

specications

Mechanical life

Operate correctly and

manage properly including

inspection before usage and

regular check-ups

Load Chain

Loading...

Loading...