9

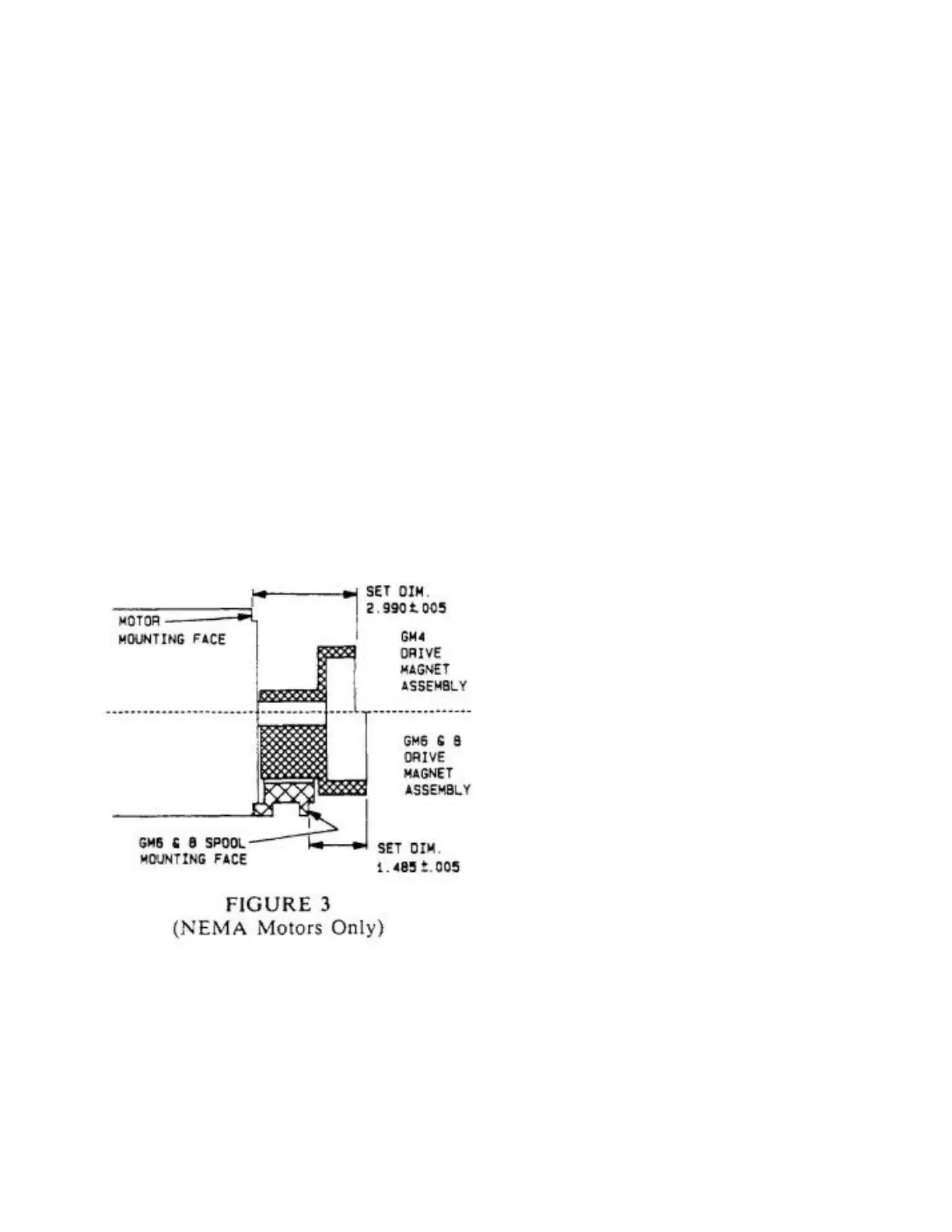

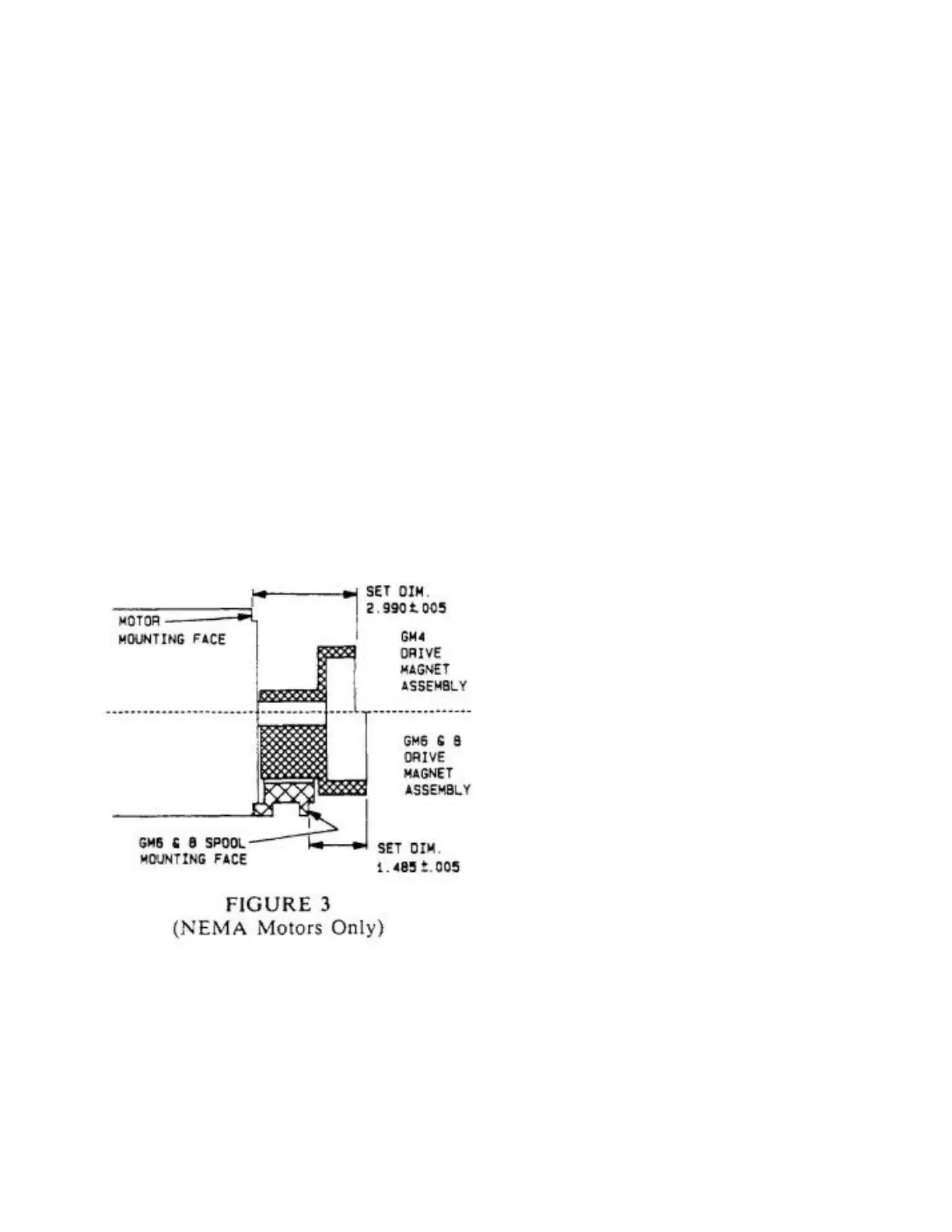

7. Install the drive magnet assembly (Item 21)

onto the motor shaft to the dimension shown in

Figure 4. If the motor is metric install the motor

adaptor (Item 29) using motor bolts (Item 25) to

the motor at this time. Also install the drive

magnet assembly onto the motor shaft until it

butts up against the shoulder on the motor

shaft. Tighten the drive magnet setscrews (Item

24) to 35 inch lbs. (395 Ncm). These setscrews

have a special nylon patch applied to the

threads to prevent loosening.

8. Carefully assemble the motor/drive magnet

assembly to the pump casing. Be careful not

to chip the drive magnets when slipping them

over the can or to pinch your fingers when the

two assemblies snap together. The use of (4)

assembly guide pins (Part #79637) is

suggested. Use guide pin (Part #49639) for

metric motors. See Figure 2. Install motor bolts

(Item 25) or adaptor bolts (Item 30) for metric

motors.

.

9. Reinstall pump in system, open inlet and

discharge valves and start pump. Monitor pump

for 5-10 minutes for signs of binding, excessive

noise and motor amperage draw. Check

performance. If problems are encountered refer

to the Troubleshooting Section.

GMC6 & GMC8 SERIES REFERENCE

DRAWINGS: SD2580

DISASSEMBLY

1. Close discharge and suction valves.

2. Disconnect power source to motor.

3. Flush and drain pump then remove pump from

the piping. Do not forget to drain the can area

through the front housing drain plug (Item 27).

4. Remove the four casing bolts (Item 35) which

are orientated vertically and horizontally.

Do not remove the motor bolts (Item 23) or the

recessed front housing bolts (Item 26) which

have protective plugs and are orientated at 45°

to vertical and horizontal, at this time.

5. Separate the spool and casing (Item 20) by

pulling them apart. This will take physical force

because you are pulling against the magnetic

attraction of the drive to the driven magnet. Do

not pry but pull straight apart.

6. Do not remove the drive magnet assembly

(Item 21) from the motor unless it or the motor

are to be replaced. This will make reassembly

easier later. The drive magnet assembly is

removed by loosening the setscrews (Item 24)

and sliding it off the motor shaft. Access to the

setscrews is provided through hole in the

spool. Remove the spool from the motor at this

time if desired.

7. Remove the recessed front housing bolts. You must

first remove the protective plug. This will allow the

casing and can (Item 19) to be separated from the

front housing (Item 3). Note: Any remaining fluid

left in the can will now drain out.

8. Remove the retaining ring (Item 14) on the

Loading...

Loading...