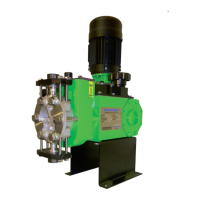

What to do if Pulsafeeder PulsaPro PP680 Water Pump has no delivery?

- KKenneth BowersAug 18, 2025

If your Pulsafeeder Water Pump isn't delivering, first check the power source and wiring diagram to ensure the motor is running. Make sure the supply tank isn't empty and that lines and strainers aren't clogged. Open any closed line valves and clean/inspect ball check valves. Increase suction pressure to address vapor lock or cavitation. Re-prime the pump, checking for leaks, and re-prime the pump if the hydraulic system is under-primed.