Page 35 of 52

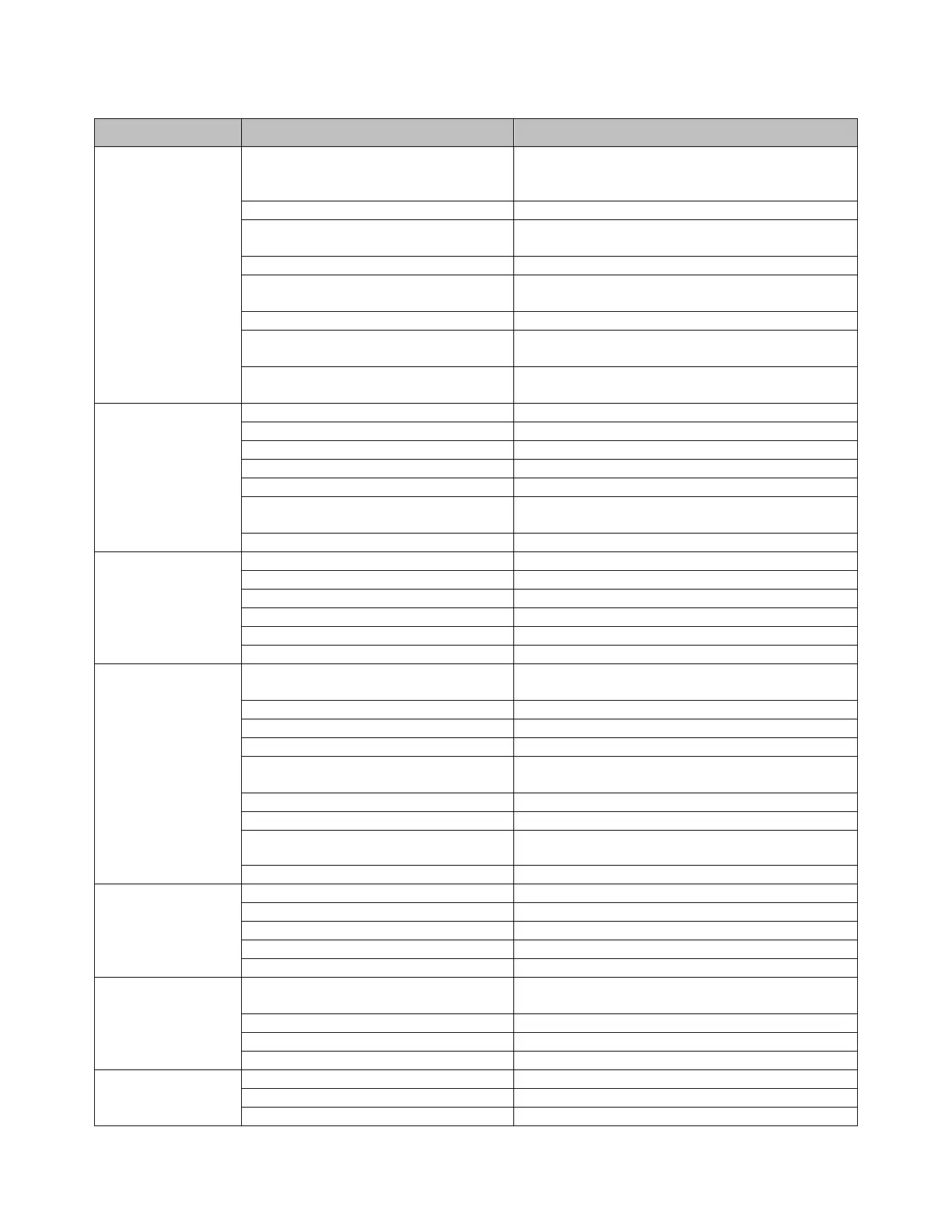

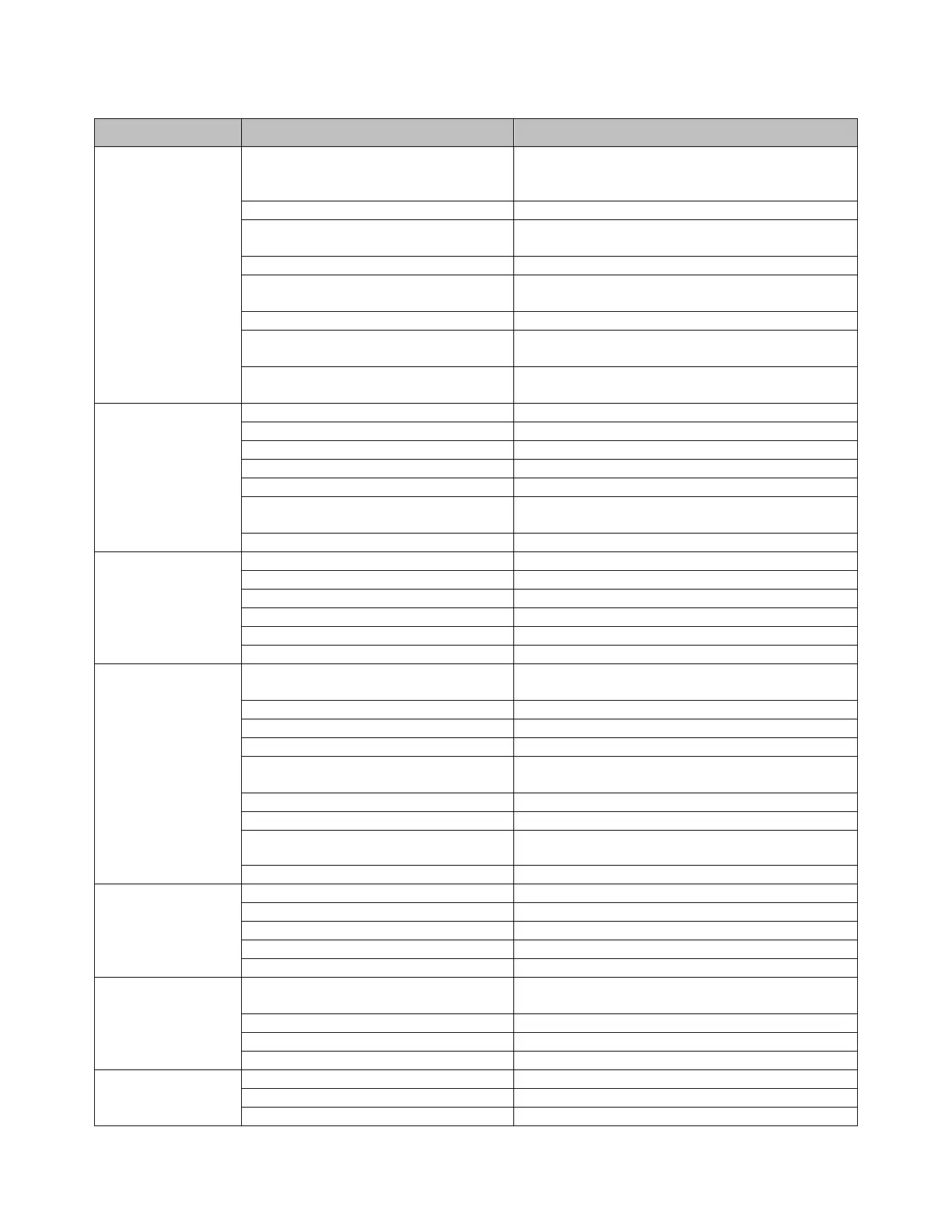

9. Troubleshooting Chart

Flow Rate Lower

than Expected

Motor Speed too low

Check voltages, frequency, wiring, and terminal

connections. Check nameplates vs.

Check Valves worn or dirty

Clean, replace if damaged

Hydraulic bypass valve operating

each stroke

Refer to Hydraulic Bypass Valve

Product Viscosity too high

Lower viscosity. Increase pump and/or piping

size

Increase suction pressure

Piston seal worn or damaged by

contamination

Inspect and replace if necessary, refer to

Piston Seal (Section 8 Maintenance)

Process pressure relief valve leaking

or relieving

Repair, adjust or replace

Delivery

gradually drops

Clean, replace if damaged

Correct for bypass valve leakage

Piston seal worn or damaged by

contamination

Inspect and replace if necessary, refer to

Piston seal

Pump does not

start

Blown fuse, and circuit breaker

Replace – eliminate overload

Check wiring diagram and correct

No Delivery

Check power source. Check wiring diagram

Ball check valves held open with

solids

Increase suction pressure

Re-prime, and check for leak

Remove and clean, replace screen if necessary

Hydraulic system under-primed

Delivery Erratic

Increase suction pressure

Entrapped air or gas in product

Ensure proper venting of system

Check voltage and frequency

Clean, replace if necessary

Delivery higher

than rated

Suction pressure higher than

discharge pressure

Install backpressure valve or consult factory for

piping recommendations

Back pressure valve set too low

Back pressure valve leaks

Repair, clean, or replace

Pump loses

Loading...

Loading...