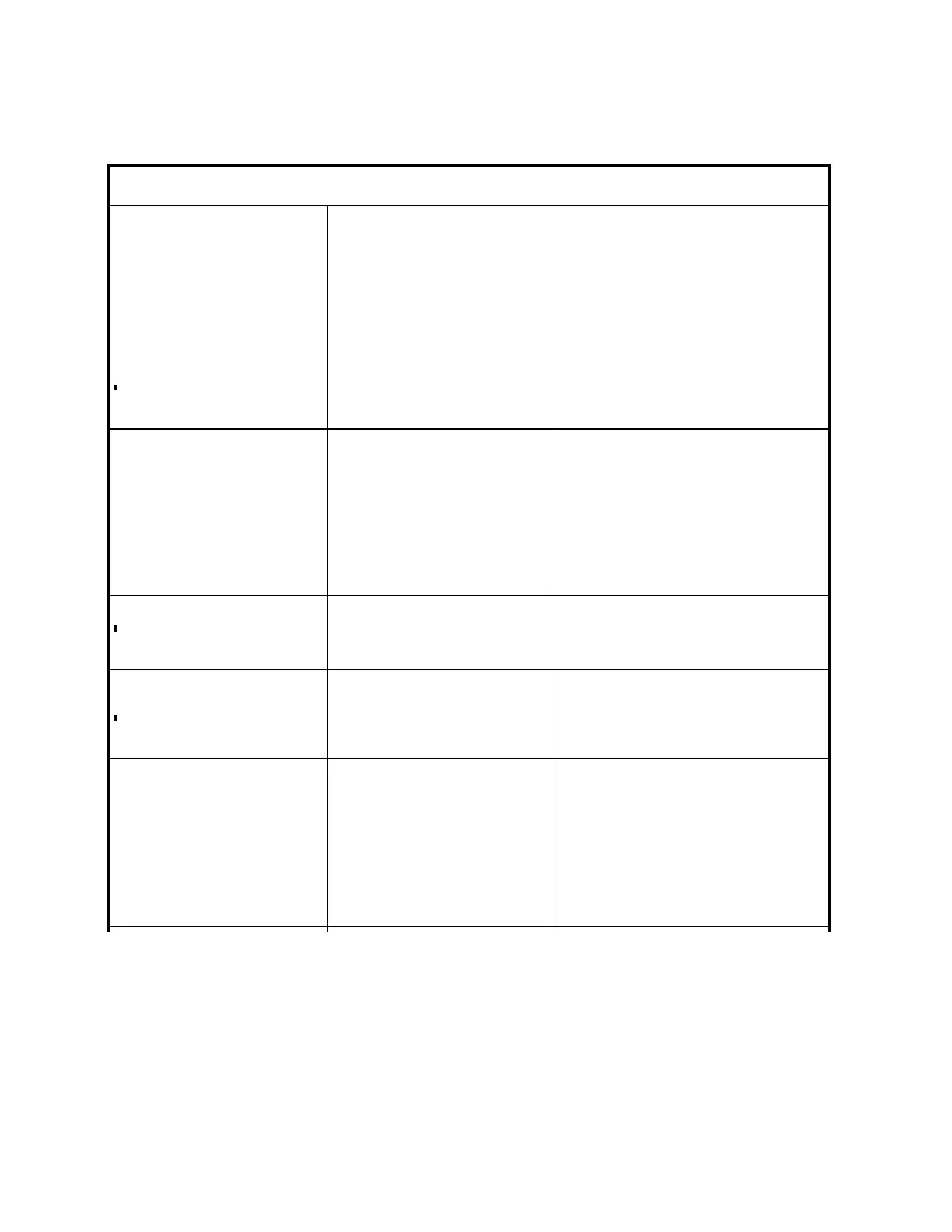

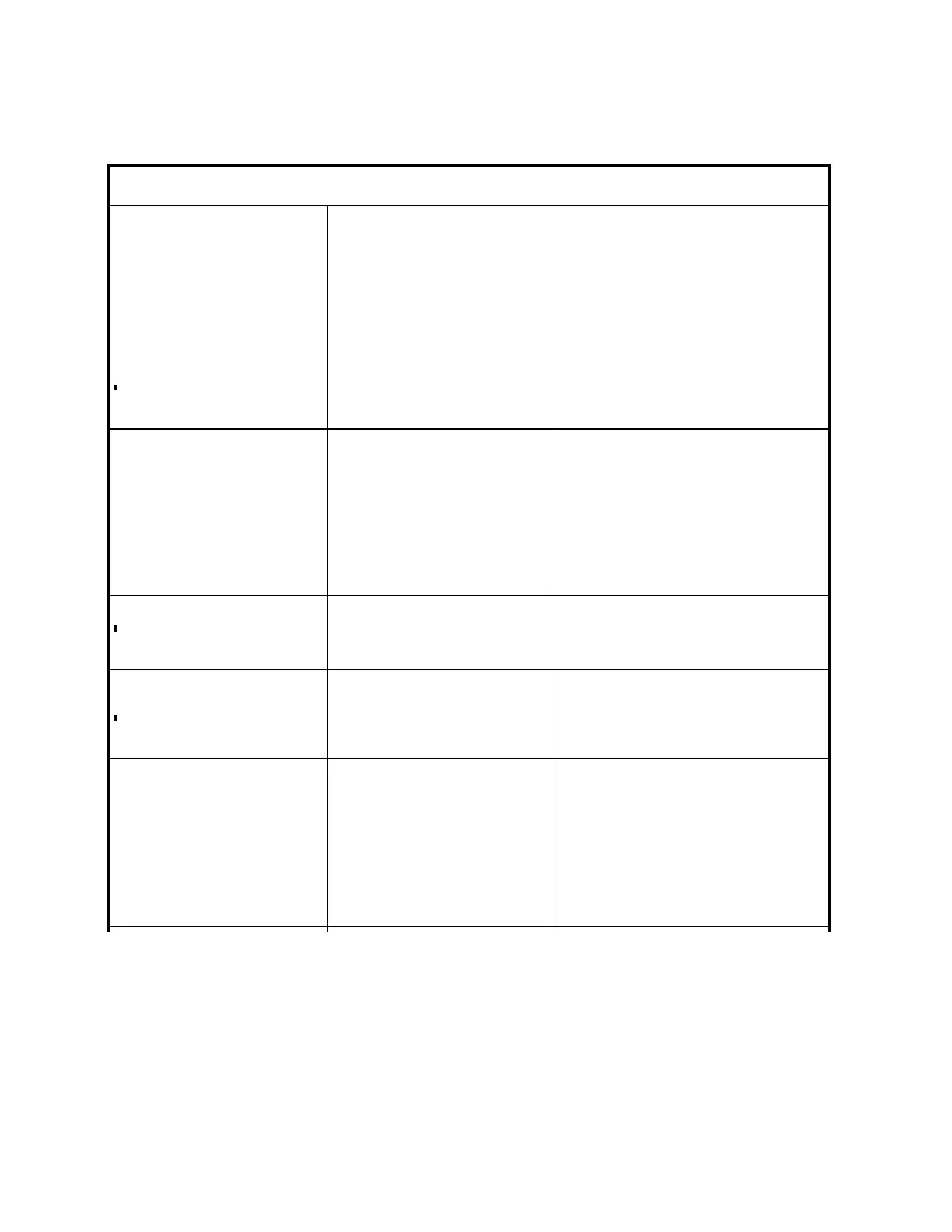

14

I

DIFFICULTY

I

PROBABLE CAUSE

I

REMEDY

1. Pump not primed.

2. Suction and/or discharge valve

closed.

3. Wrong direction or rotation.

4. Suction plugged.

5. Air leak in suction.

6. Suction lift too high.

7. Motor incorrectly wired.

8.

Magnetic coupling decoupled.

1. Prime pump.

2. Open valves.

3. Reverse rotation

4. Eliminate plug.

5. Locate and repair leak.

6. Do not exceed vapor pressure of

liquid.

7. Check wiring diagram.

8. Stop motor, eliminate discharge

blockage or foreign matter jamming

gears and restart. If no blockage

exists verify motor supply voltage is

correct and restart.

1. Discharge pressure higher than

expected.

2. Air leak in suction.

3.

Rotational speed incorrect.

4. Inlet obstructed or clogged.

5.

Liquid viscosity higher than

expected.

6. Leaky relief valve.

7. Insufficient suction pressure.

8.

Worn or damaged internal parts.

1. Reduce pressure.

2. Locate and repair leak.

3.

Check speed and wiring

4. Remove restriction

5. Thin liquid or accept lower flow.

6. Correctly set or repair relief valve.

7. Increase suction pressure.

8.

Inspect and repair as required.

PUMP GRADUALLY

LOSES PRIME

1. Air leak in suction

2. Suction lift too high.

3.

Air or gas in liquid.

4.

Pump worn or damaged.

1. Locate and repair leak.

2. Increase suction pressure.

3. Eliminate air or gas.

4.

Inspect and repair as required.

1. Pump cavitating.

2.

Pump worn or damaged.

3.

Air or gas in liquid.

4.

Foreign particles in liquid.

1. Increase suction pressure to provide

sufficient NPSH

2. Inspect and repair as required.

3.

Eliminate air or gas.

4.

Install (or clean) strainer in inlet pipe.

MOTOR RUNS HOT OR

OVERLOADS

1. It is normal for motors to feel hot

even when not overloading.

2.

Discharge pressure too high.

3. Liquid viscosity higher than

expected.

4. Rotational speed too high.

5.

Binding internal pump parts.

6. Motor wired incorrectly.

1. Check motor amp draw to be sure.

2. Lower pressure. Check pressure relief

valve setting and for defective

discharge pressure gauge.

3. Thin liquid or install larger motor.

4. Reduce speed.

5. Inspect and correct condition.

6. Check wiring diagram.

TROUBLESHOOTING

I

Loading...

Loading...