Edition from 23.11.2017

7

PLD880. Stepper motor driver

www.purelogic.ru8 (800) 555 63 74

05. Driver functional capabilities

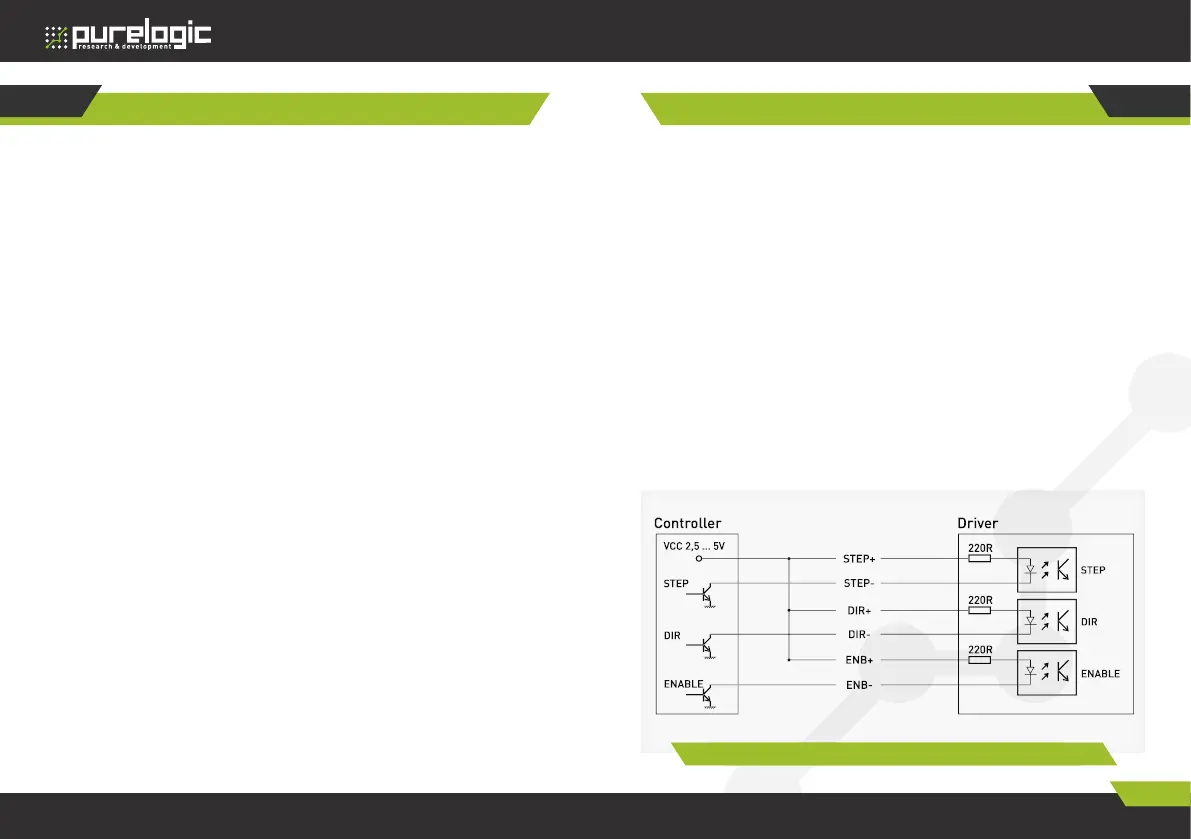

The driver operates with standard signals STEP/DIR/ENABLE.

The signals are transmitted to differential optoisolated inputs.

The scheme of differential input device and connection method to the

controller with outputs ‘open collector’ type is shown in fig.2.

STEP signal characteristics — working voltage 2.5V, 3.3V , 5V (you may

need extra current-limiting resistor connection), current consumption

up to 20mА, min signal duration is 2ms. The step is carried out on the

signal front edge.

DIR signal characteristics — working voltage 2.5V, 3.3V, 5V (you may

need extra current-limiting resistor connection), current consumption

up to 20мА, action time is 200 nsec before/after front edge STEP.

ENABLE signal characteristics — working voltage 2.5V, 3.3V, 5V

(you may need extra current-limiting resistor connection), current

consumption up to 20mА, action time is 100 ms. Logic unit (voltage is

applied to the input) – stepper motor driver is off and coils are cut off

the current, zero – stepper motor driver is on and stepper motor coils

are supplied.

Fig. 2. Differential input device

Control Signal Connections

06

05

Driver functional capabilities

• Optoisolation of module control signals STEP/DIR/ENABLE.

• Expanded discrete adjustment of working current in stepper motor

coils.

• Stepper motor softstarter. After turning on the power or ENABLE

signal, current is increasing gradually in stepper motor coils. This

allows to exclude typical bump when turning stepper motor on.

• AUTO-SLEEP mode, driver after 1 sec standstill (lack of STEP signal)

automatically enters rotor hold mode (full/half operating current) for

heating reduction.

• Coil short-circuit module protection, wrong stepper motor connection

protection.

• Over-voltage protection (back EMF effect protection).

• Polarity reversal supply voltage protection (the driver will not be

switched ON).

• Inbuilt automatic compensator of midfrequency stepper motor

resonance.

• Phase current adjustment for vibrations exclusion at low revs.

• Modifications scheme of phase current form with frequency increase

(morphing, transfer from microstep to step mode with with frequency

increase).

• Inbuilt dumper (back EMF compensation device from stepper motor).

• Inbuilt STEP generator frequency (test driver start can be performed

without PC or external generator connection).

• Optoisolated output of driver alarm signal.

• Convenient dismountable clip connectors to step motor, power source

and control signals.

• Alarm indication supplied by STEP/ENABLE frequency, inbuilt dumper

operation.

• STEP/DIR/ENABLE/ALARM signals are duplicated in DB-9M type

connector for convenient connection to PLC4x-G2.

Loading...

Loading...