Edition from 23.11.2017

11

PLD880. Stepper motor driver

www.purelogic.ru8 (800) 555 63 74

07. Current and power option

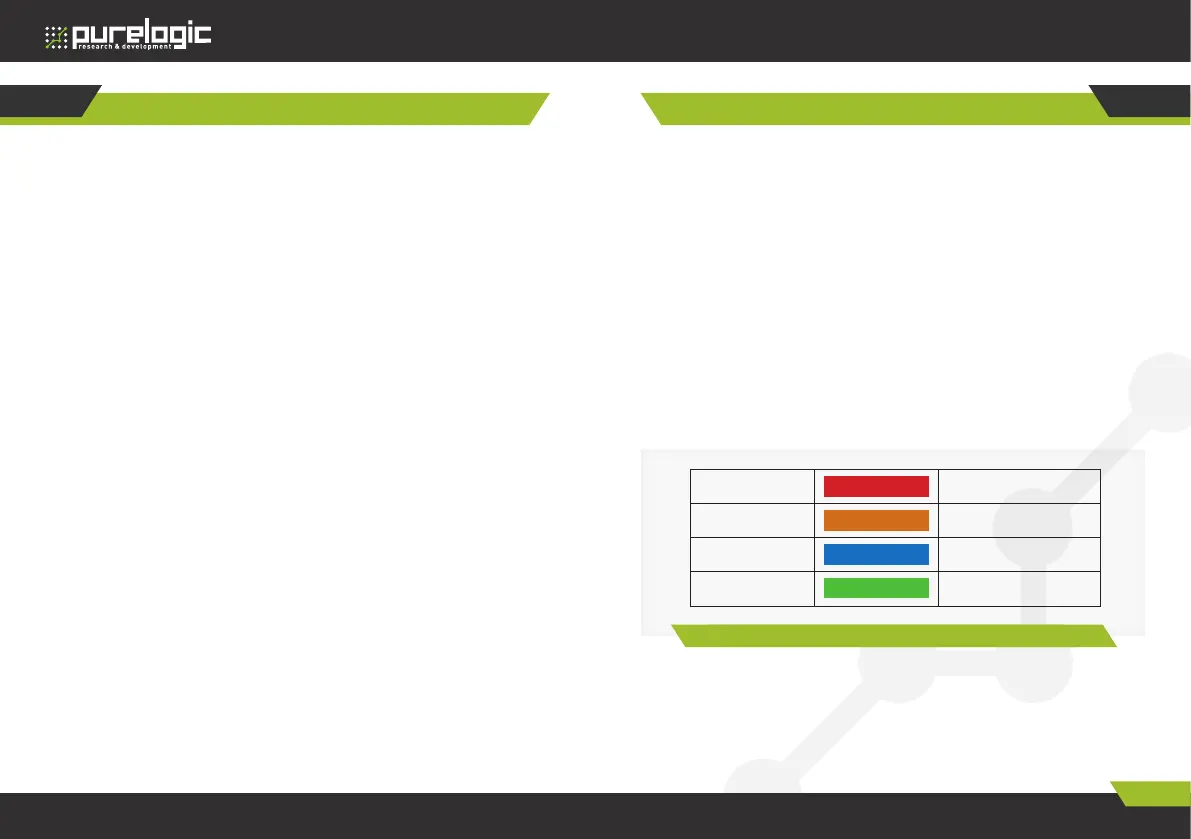

Fig. 4. Purelogic R&D stepper motor connection to the driver

PLD880 driver is optimal for control of bipolar and unipolar stepper

motors Purelogic R&D series PL86.

Stepper motor connection to the driver is performed as it is shown in

fig.2 (clips PH1.1[+A], PH1.2[-A] и PH2.1[+B], PH2.2[-B]).

The driver has protection against wrong stepper motor coil connection

and coils linked together / ‘+’ power supply.

Purelogic R&D stepper motor connection to the driver is performed

according to fig. 4.

Please note in case of changing phases PH1.x<>PH2.x, the motor

will start rotating in the opposite direction (inversion analogue of DIR

signal).

The length of wires leading to the stepper motor from the driver must

not exceed 10 meters. Longer wires can lead to driver’s work failures.

It is strongly recommended to interlace the stepper motor wires per

phase, then put this braid to the screened metal sheath. Sheathes and

stepper motor frame must be grounded.

PH1.1 [+А] Red (RED)

PH1.2 [-А] Orange (ORG)

PH2.1 [+B] Blue (BLU)

PH2.2 [-B] Green (GRN)

Stepper motor connection to the driver

08

Max supply voltage driver option depends on the applied stepper motor

and desired max rotation speed. Optimal supply voltage calculation

for the stepper motor is carried out according to the formula U=32*v

(stepper motor phase inductance mH), but not more than 80V.

Supply current must be chosen 50...70% from the claimed stepper

motor coil current.

Working current setting is performed by DIP-switches (current value is

set up by SW1, SW2, SW3 and multiplier factor SW4).

Phase current adaptation (stepper motor smooth running) is carried

out by PHASE TRIM potentiometer when vibrations and uneven stepping

at low revs is found.

Adaption strategy is as follows:

1) A potentiometer is set to the extreme left position (minimum value).

2) Stepper motor is connected, voltage is supplied, vibration frequency

is set up by STEP frequency generator.

3) PHASE TRIM potentiometer moves to ¼ while rotating PH2(A) TRIM ,

the vibration reduces.

If there are still vibrations, PH1(A) TRIM potentiometer moves to ¼

again, rotating PH2(A) TRIM, the vibration reduces, etc. You may fail to

reduce vibrations totally because of stepper motor specifics.

When there is no STEP signal for more than 1 sec, the driver goes to

AUTO-SLEEP mode and reduces the coil current to the value identified

by DIP-switch SW5.

POWER OFF DEVICE BEFORE MAKING ANY SWITCH-OVERS.

07

Current and power option

Loading...

Loading...