Page 111061DOC Rev C

Effective date: 6-Mar-14

RAMVAC Bison

®

User GuideMaintenance

RAMVAC preventive maintenance is simple, clean, and inexpensive, however we recommend that all maintenance and service be provided

by a trained dealer service technician.

It can help ensure your RAMVAC provides years of predictable performance.

Key points for trouble-free operation:

• Rinse vacuum lines daily with the recommended quantity of liquid.

• Change oil and check lters on schedule.

Upon request, RAMVAC will provide circuit diagrams, component parts lists, descriptions, calibration instructions,

or other information to assist service personnel to repair parts.

Maintenance Overview

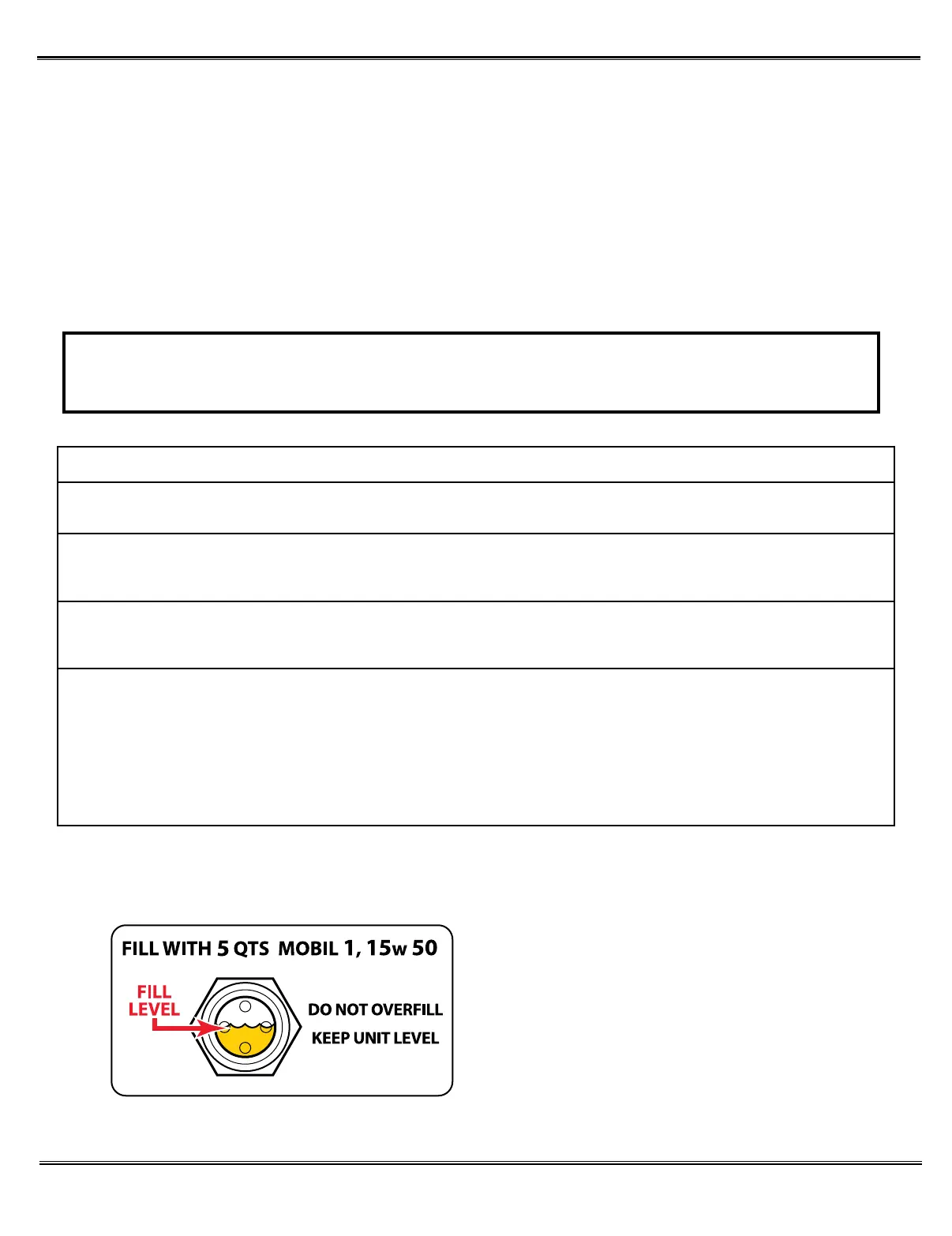

To read correctly, get eye level with sight glass

while unit is sitting level, and check that oil level

is even with the head of the red arrow. Add or

drain oil accordingly.

Oil Fill Level

Preventative Maintenance Schedule

1st Week Check Drip Rate See “Check Oil Drip Rate”

Daily Rinse Vacuum Lines See “Cleaning the Vacuum System”

Every 1,000 hours Check Air Filters See “Air Filters”

Check Drip Rate See “Check Oil Drip Rate”

Every 2,000 hours* Change Oil and check oil lter See “Oil Change”

Check V-Belt See “Check V-Belt”

The S2 will display the number of hours before maintenance is due.

If a Lighted remote switch is installed it will also ash the light indicating that maintenance is due.

If the OWL Touch is installed it will indicate the maintenance is due on the display.

Loading...

Loading...