34

LUBRICATION AND MAINTENANCE

Barrels of lubricant should be kept under cover,

preferably in a clean, dry place, and should be

clearly marked to indicate the lubricant which they

contain.

When a barrel is kept in an exposed location, it

should be tilted to allow any moisture to run away

from the filler cap. Always use a clean container

when transferring oil from a barrel to the tractor and

make sure that any cap or plug, which has been

removed, is installed as soon as possible.

FUEL AND LUBRICANT SERVICE

PROCEDURES

ENGINE

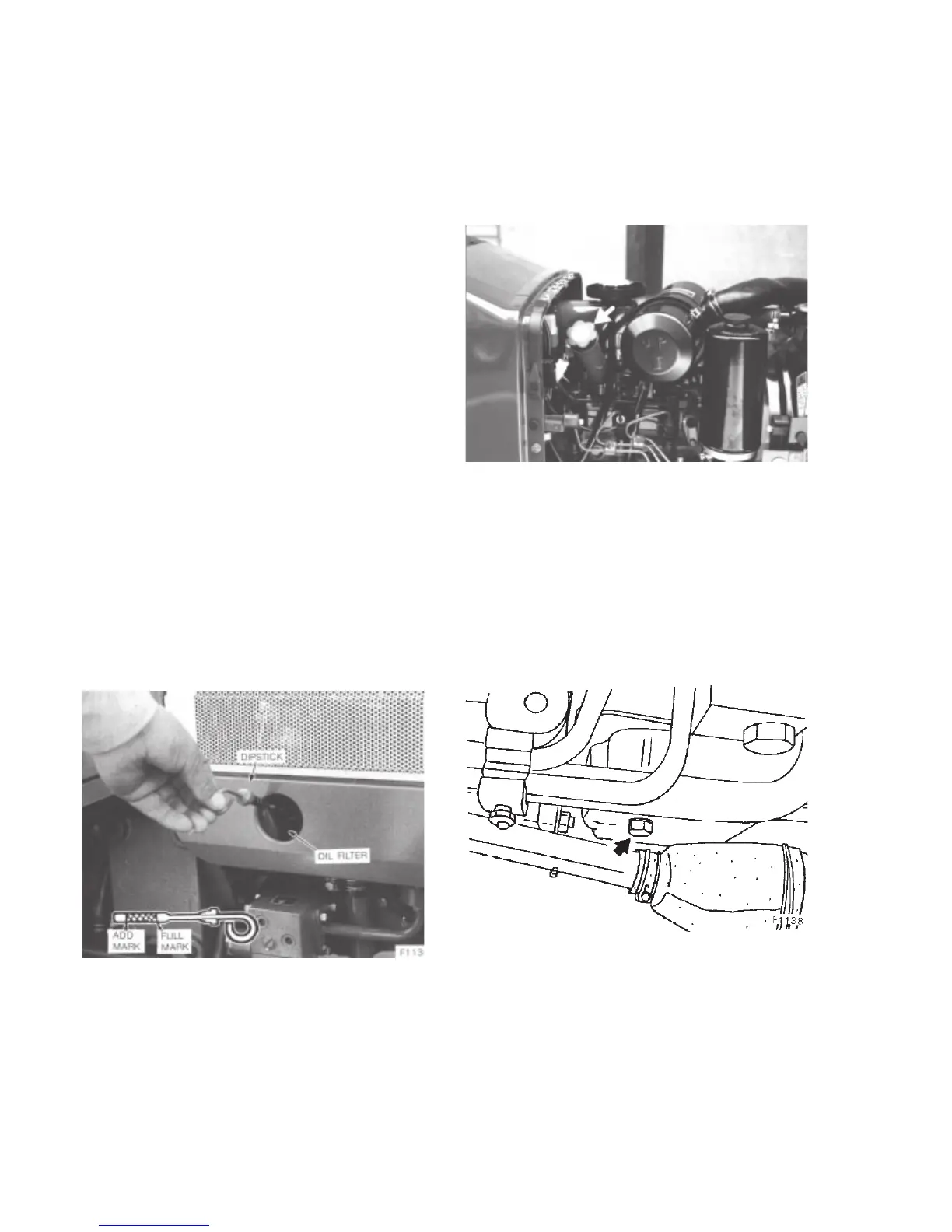

Checking Oil Level: Check the engine oil level

daily or every 10 hours.

1 .With the tractor standing level, and after the

engine has been stopped for a period of time, check

the oil level with the dipstick, Figure 40.

Figure 40 - Engine Oil Level Dipstick and Filter

2.lf the oil level is low, remove the filler cap, Figure

41 and add oil to the engine through the filler hole to

bring the oil level between the marks on the dipstick.

Be careful not to overfill.

3. Install the oil filler cap.

Figure 41 - Engine Oil Filler Cap

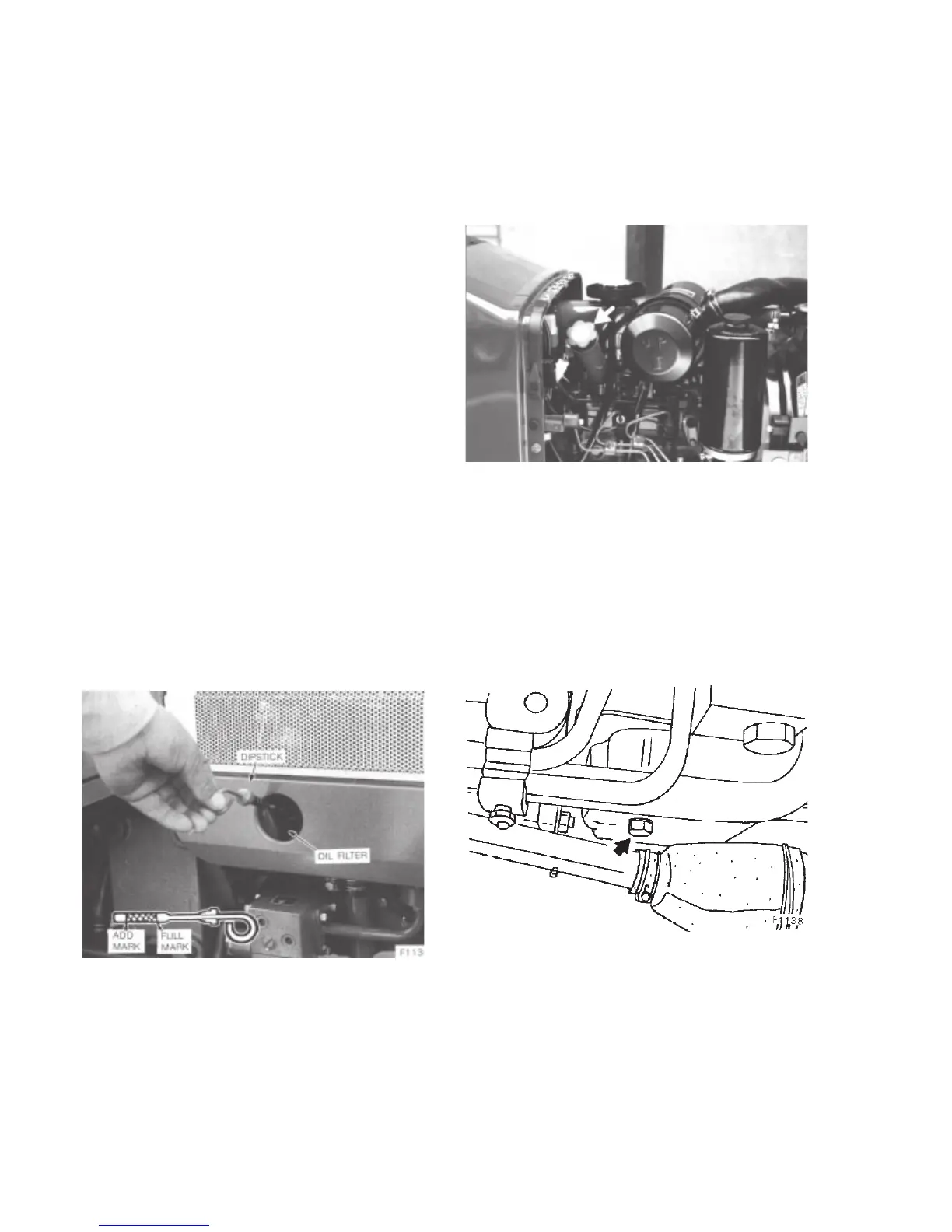

Changing Oil and Filter: Change the engine oil

every 100 hours and the engine oil filter every 200

hours.

Figure 42 - Engine Oil Drain Plug

NOTE: Oil intervals should be adjusted according to

sulphur-content of diesel fuel. The use of fuel with a

sulphur content over 1.3% is not recommended.

Sulphur Content, % Oil Change Interval

BelowO.5 Normal

0.5 - 1.0 1/2 Normal

Over 1.0 1/4 Normal

Loading...

Loading...