7

Technical Principle

Principle of LCD photocuring 3D printing technology

The core mechanism of light curing 3D printing technology is the light-curing chemical reaction that

photosensitive resin will undergo light-curing reaction and instantly change from liquid to solid when it

encounters 405 nm blue light.

RAYSHAPE Edge E1 3D printer uses the mature monochrome LCD technology to make the reaction process

controllable.

Step 1: ShapeWare 3D printing software will process the STL file you need to print into a slicing file.

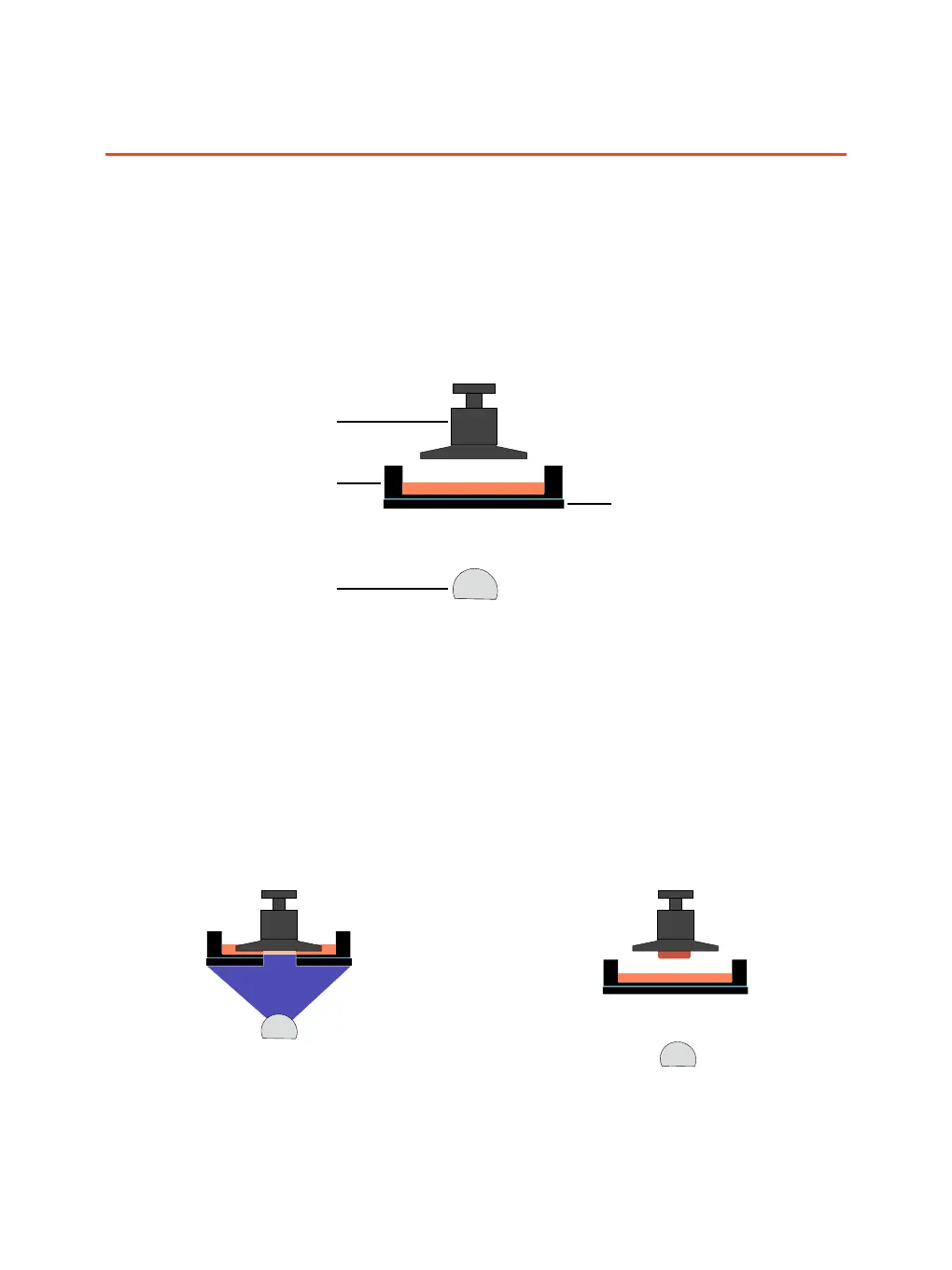

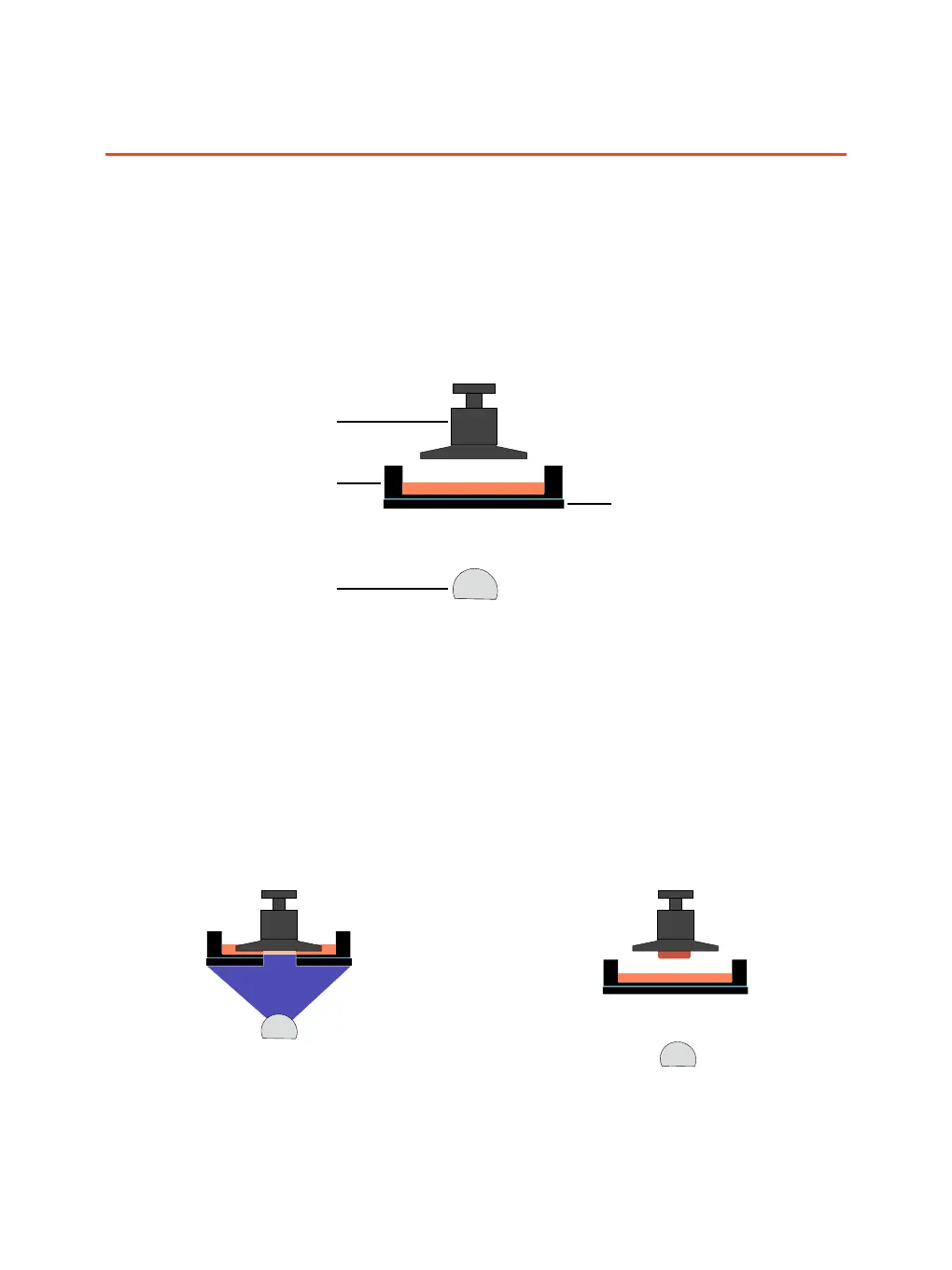

Step 2: Additive manufacturing: the above figure is the structural schematic diagram of E1 3D printer. The resin

tank contains photosensitive resin. In the first stage of printing, the printing platform that can move up and down

on the Z axis is close to the bottom of the resin tank. The LCD screen projects a slice image of the model to be

printed. The image is imaged at the bottom of the resin tank and bonded to the printing platform. After one layer

is cured, the printing platform in the second stage is lifted up to a certain height, Separate the printed first layer

from the bottom. In this cycle, press it down to a certain distance from the bottom, and then the LCD screen

projection solidifies the next layer until all the slices are printed.

Stage 1: Printing platform descend and LED on Stage 2: Printing platform rise and

separate from the bottomon

Printing platform

Resin tank

LCD screen

LED light source

Loading...

Loading...