SETUP & OPERATON HeatNet Control V3

Page 20

available” state, it can still be fired locally and failsafe is

still available.

SETUP: AUX FUNCTIONS: HEAT EXCHANGER:

SEND RETURN:

OFF The Master sends its return

temperature to all boilers

RETURN The Master sends its return

temperature to all boilers

SYS RET The Master sends the system

return temperature to all boilers

SETUP: AUX FUNCTIONS: HEAT EXCHANGER:

LOW TEMP:

OFF No check is made to the return

temperature – boiler remains

online

RETURN Uses the boilers own return

sensor (No pump /valve present)

SYS RETURN Uses the System Return temp

received from the Master Boiler

(its Local or System Return).

SETUP: AUX FUNCTIONS: HEAT EXCHANGER:

TEMP < 140F

Adjustable threshold temperature below which the

boiler will take itself offline.

1 degree F of hysteresis is provided so as to not

toggle offline<-to->online at the threshold temp.

Since the FIII boiler is non-condensing, the efficiency vs.

input is relatively flat. The MOD MAX value will not have

the same impact if the FIII non-condensing boilers were

placed in the Priority 1 set.

Futera III/ Fusion Boiler BTU Chart

In the Mixed Boiler System table (Figure 15) line 2

example, (2) CB/CW 500s are set as Priority 1 and (3)

MB/MW 1250s set as Priority 2. With a MOD MAX of

60%, each 500 can run to 300M (600M total) before a 1250

is called ON (Add Delay timer). Once both 500s are running

and the 1250 is called on and running, all (3) boilers will

drop to a total of the 600M BTUs: The sum of the 500, 500,

and 1250 would equal about 27% modulation: (.27 * 500M)

+ (.27 * 500M) + (.27 * 1.25MM) or: 135M +135M + 337M

= 607M and operate at higher combustion efficiencies: 27%

is roughly between the top two lines on the Typical

Efficiency of Condensing Boilers chart.

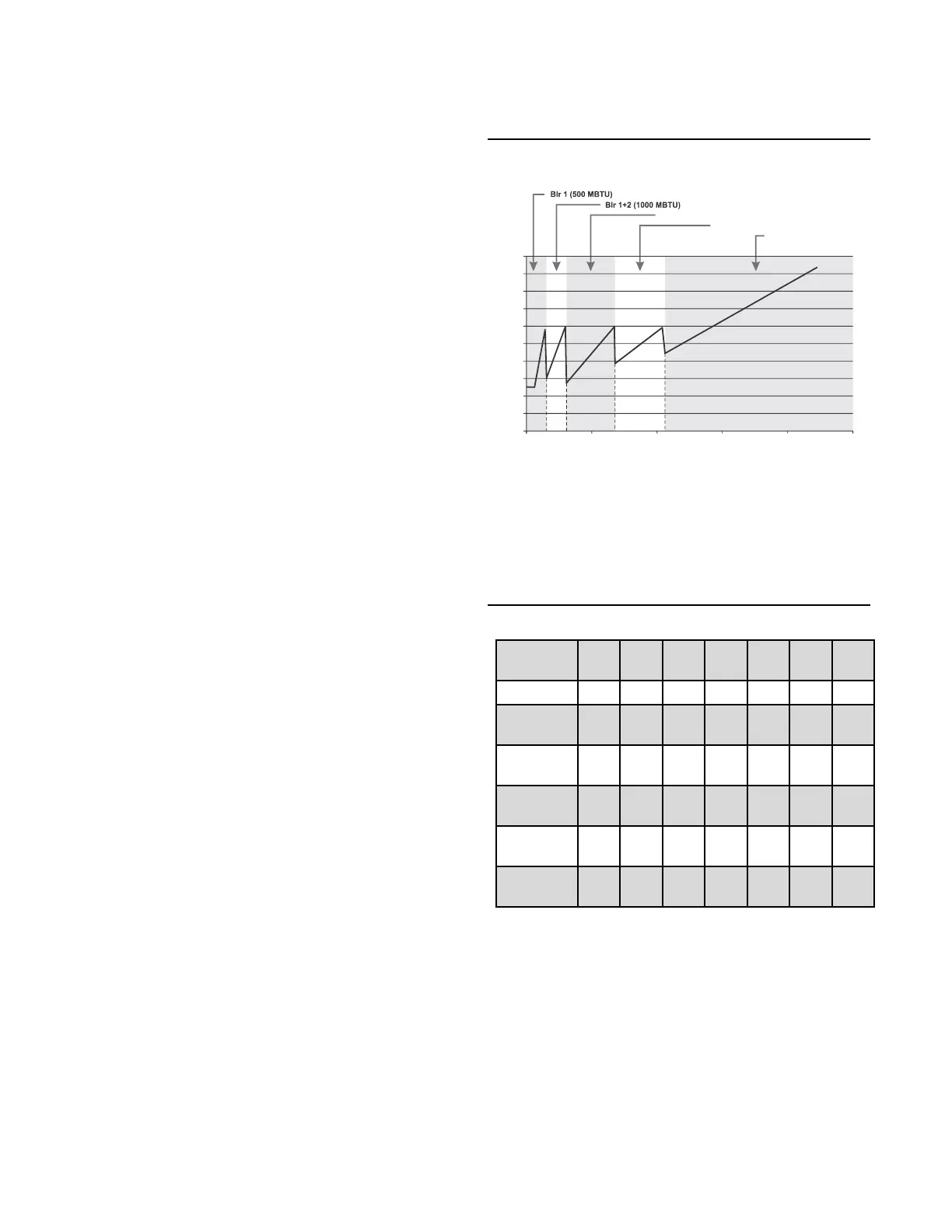

The Boiler System Response 5 chart illustrates how each

boiler (in the example) is brought on and fires to 60%, drops

to a lower fire rate and then adds the next boiler (vertical

dashed lines). Once all boilers are firing, the modulation is

released allowing all boilers to fire to 100%.

Figure 15 Boiler System Response 5

(2) CB/CW 500s, (3) MB/MW 1250s

So, for the first 600 MBTH of load, the combustion

efficiency is maximized by running the (2) fusion boilers

from low to middle input rates. Running the (2) fusion

boilers first also has the added effect of minimizing the

return water temperatures of <140F from reaching the

noncondensing boilers.

Figure 16 Futera III/Fusion Boiler Btu Chart (MBH)

Loading...

Loading...