SETUP & OPERATON HeatNet Control V3

Page 18

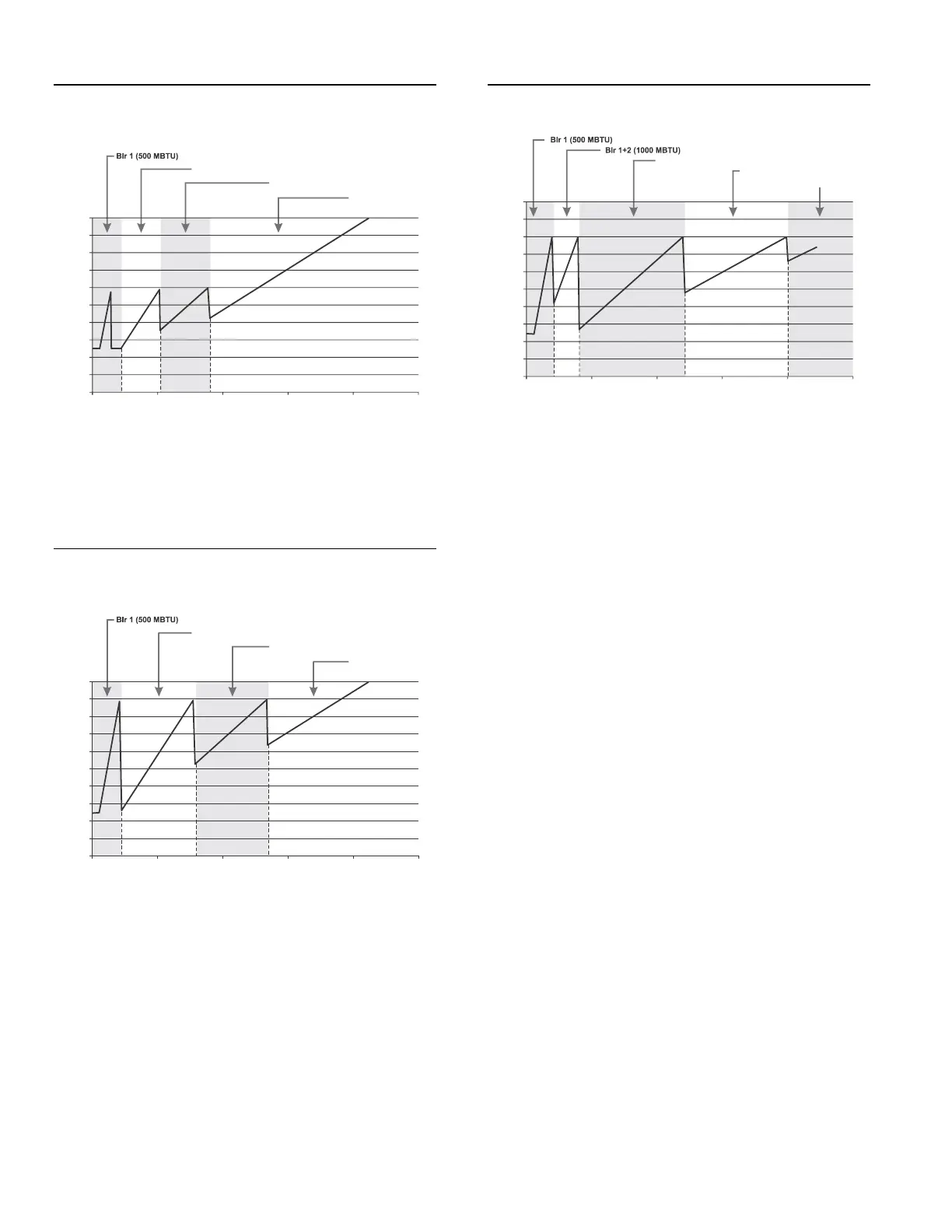

Figure 10 Boiler System Response 2

(1) MB/MW 500, (3) MB/MW 1250, 60% Mod-

Max

To correct this would require the MB/MW 500 to set the

MOD-MAX to roughly 90% (Boiler System Response 3: not

as efficient as it could be when using CB/CW Fusion

boilers) in order to have a linear BTU transfer when the

MB/MW 1250 is added (fired).

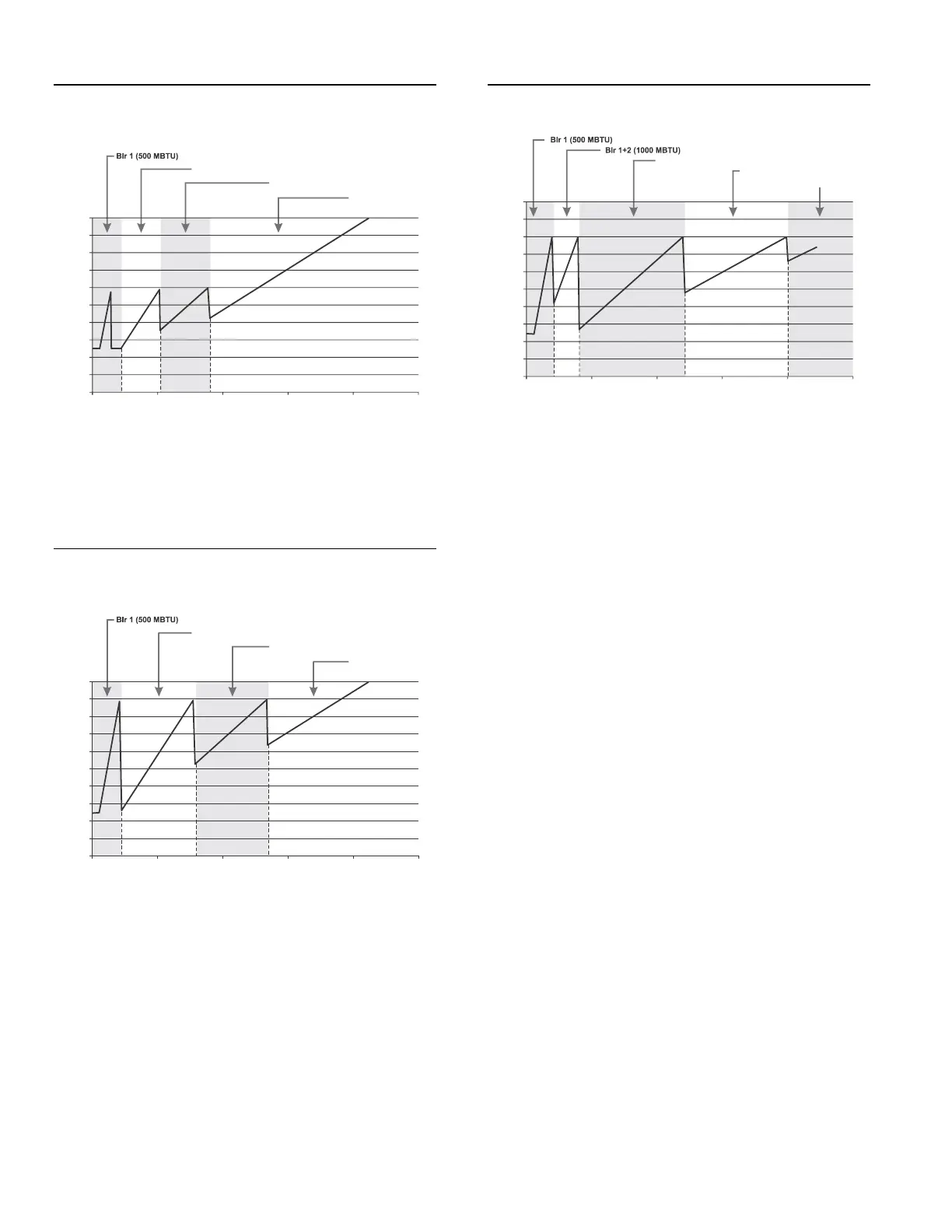

Figure 11 Boiler System Response 3

(1) MB/MW 500, (3) MB/MW 1250, 90% Mod-

Max

An MB/MW 500 running with a MB/MW 1250 may not be

an optimal choice unless (2) MB/MW 500s are used in the

Priority 1 set or (3) MB/MW 500s and one is allowed to be

taken offline.

A system employing this redundancy where (1) is allowed

to be taken offline is listed in the MIXED BOILER SYSTEM

chart. This system uses (3) MB/MW 500s and (3) MB/MW

1500s. Two of the MB/MW 500s are treated as one when

adding the min inputs of the Priority 1 set.

Figure 12 Boiler System Response 4

(2) MB/MW 500s, (3) MB/MW 2000s

The Boiler System Response 4 graph illustrates another

system where 80% is used as the MOD-MAX clamp. With

this example, when using all non-condensing boilers, the

system can maximize the use of the smaller boilers before

calling the larger ones.

In summary, the system should be tuned using the boiler

selection charts and the MOD-MAX value. Since selecting

the Priority 1 boiler is integral to the fault tolerance of the

system, it is important to note any discontinuities in BTUs if

a Priority 1 boiler fails when multiple Priority 1 boilers are

used.

Mixed System Type 2:

Condensing / Non-Condensing

This mixed system may also have mixed boilers with

differing sizes as outlined in the Mixed System Type 1:

High System Turndown section. In the following examples

condensing high mass boilers will be used with non-

condensing low mass boilers. The reason for creating a

mixed system is primarily to control the system cost.

Loading...

Loading...