RM-216 C.10 Easy Line Documentation

RDN 10000029 16 13.05.2014

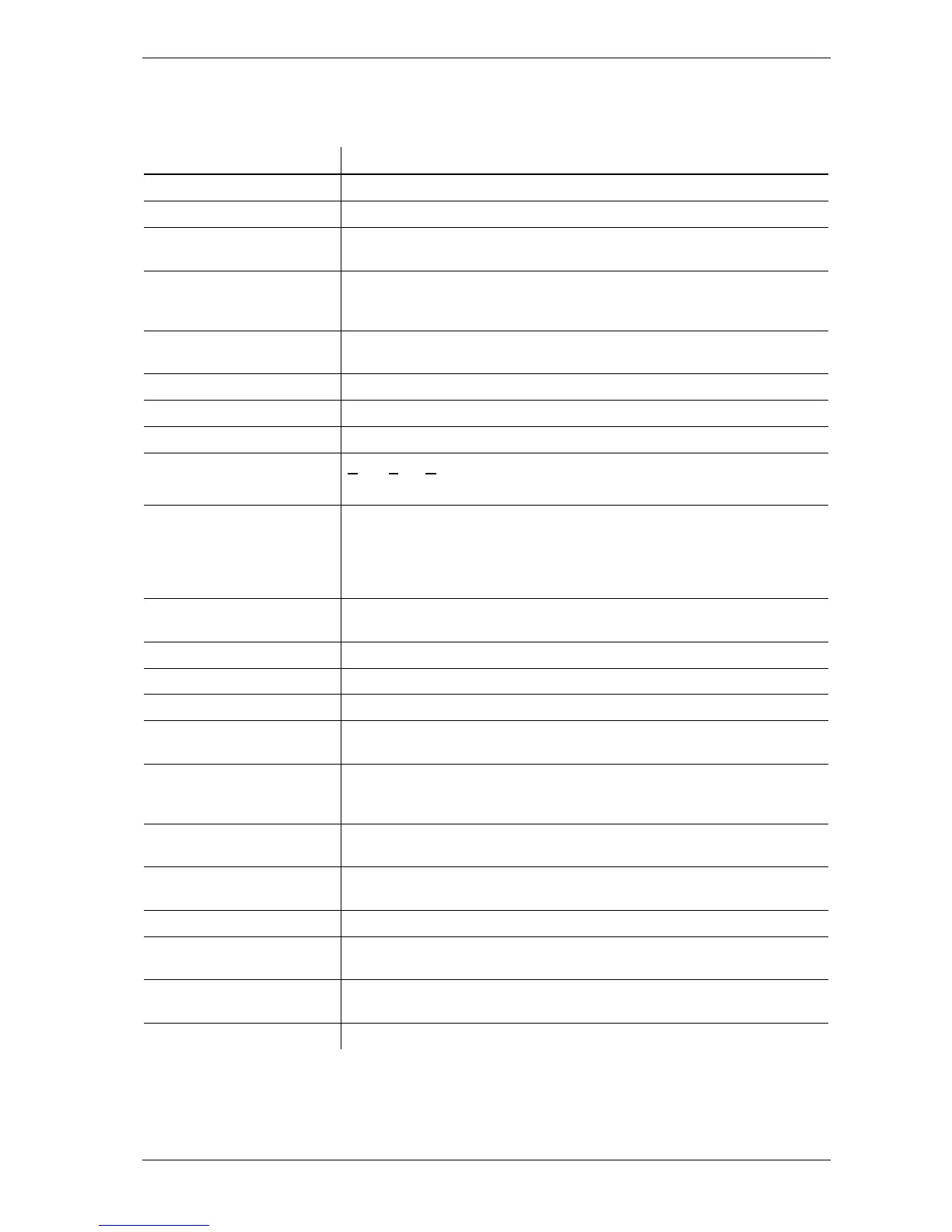

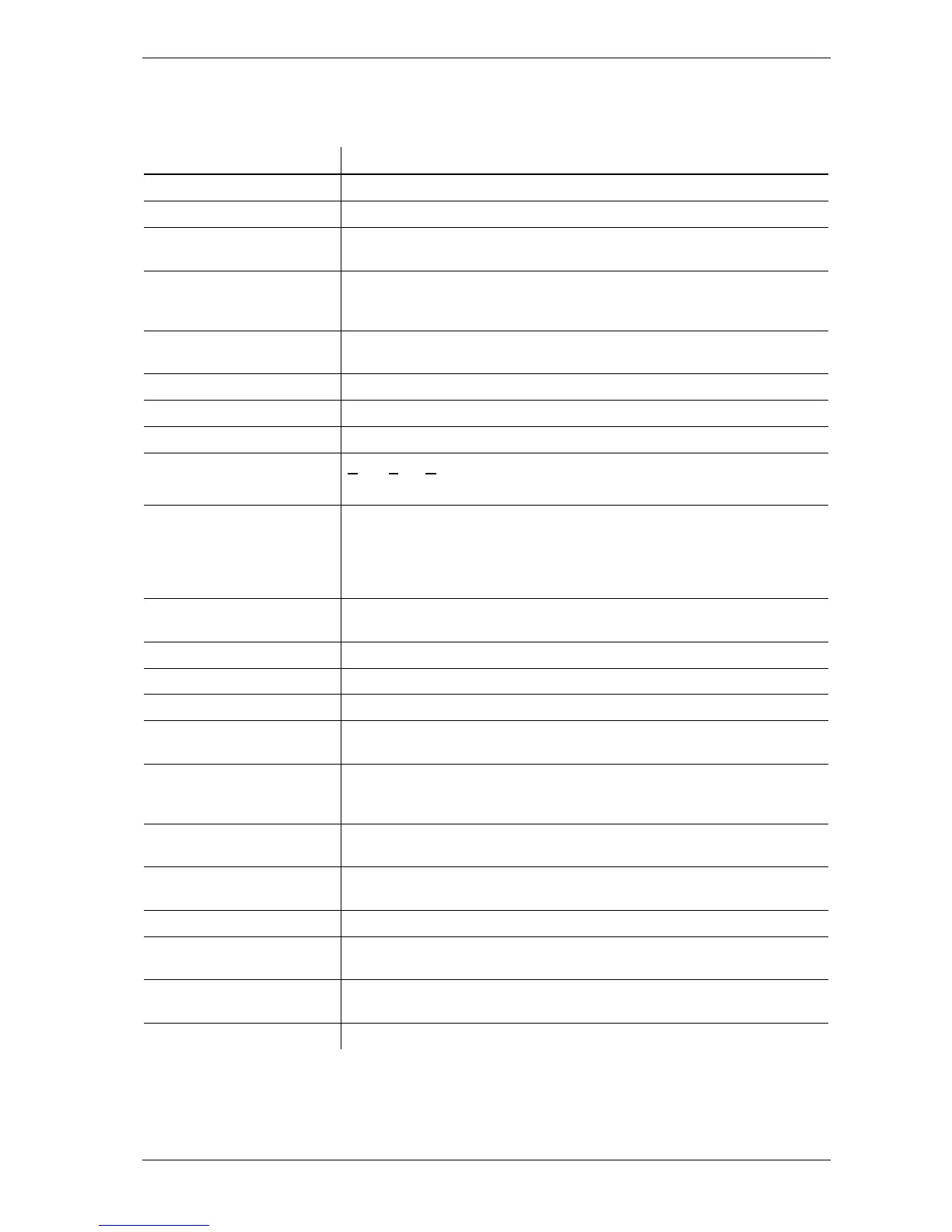

10 Glossary

Term Explanation

Bulkhead connector Connections for fitting the differential pressure measurement hoses.

Cleaning Cleaning the filter elements using compressed air pulses.

Compressed air pulse

cleaning

Cleaning of the filter elements using compressed air pulses.

Differential pressure Difference between the air pressures ∆p on the pure gas side (behind

the filter element) and the crude gas side (in front of the filter element) of

the filter.

Down time cleaning Cleaning the filter elements after the system is shut down for a set

duration or number of cycles.

Down time cleaning cycles The number of cleaning cycles performed in the down time cleaning.

Down time cleaning input Input on the RM-216 C for starting the down time cleaning.

Down time interval time Pause time during the down time cleaning.

DTC mode Down Time Cleaning mode

The way in which the down time cleaning is started.

Expansion module If the filter has more than 16 valves, expansion modules of type RM-LV8

(for 8 valves) or RM-LV16 (for 16 valves) are required. A maximum of 7

type RM-LV16 expansion modules can be connected to the main

RM-216 C equipment. With the outputs on the main equipment, this

makes a maximum of 128 valve outputs available.

Extractor element Device for extracting the filter casing from the dust deposited. E.g.

cellular wheel sluice, through conveyor worm.

Extractor element contactor Contactor which switches an extractor element drive unit on and off.

I/O module Input/output module (module for the input and output of control signals)

Operation mode Status of the RM-216 C in which the equipment is ready for operation.

Parameter selection mode Status of the RM-216 C in which the equipment operator can select a

parameter.

Parameter setting lock The parameters P03, P06, P07, P08, P09, P13 and P18 are protected

by a setting lock at the factory. If the values need to be changed, the

parameter P20 “Setting lock" Must be set to the value “Off”.

Parameter setting mode Status of the RM-216 C in which the equipment operator can set a

parameter.

Pause time

(also Interval time)

Time period between two consecutive control pulses from the valve

outputs when the cleaning is running.

Pulse time Duration of a control pulse on the valve outputs.

Service operating hours

alarm

Alarm issued when the operating hours set for the maintenance interval

has elapsed.

Service operating hours

code

Code which needs to be entered to change the set value for the service

operating hours.

Setting lock See Parameter setting lock

Loading...

Loading...