INSTALLATION

Typical Installation

3

INSTALLATION

Typical Installation

Physical Installation

1. Install the pump in the center of a suitable gas-tight basin that is at least 18-inches diameter and

24-inches deep.

• Provide adequate room for future servicing, protection from freezing temperatures, flooding,

and equipment drainage.

• Never place the pump directly on clay, earth, or gravel surfaces.

• Ensure sump is clean and free of nails, gravel, string, cloth, or other debris before installing.

IMPORTANT: Do not attempt to restrict the intake side of the pump.

2. Connect discharge piping, using pipe joint compound at all connections.

• The discharge pipe should be as short as possible and contain as few elbows as possible.

• Ensure piping is the same diameter as the discharge port.

• If reduced flow rates are required, place a valve on the discharge side of the pump.

3. Install a union in the discharge line just above the basin cover.

4. Install a free flow check valve in the discharge line that will easily pass

11

/

16

-inch solids.

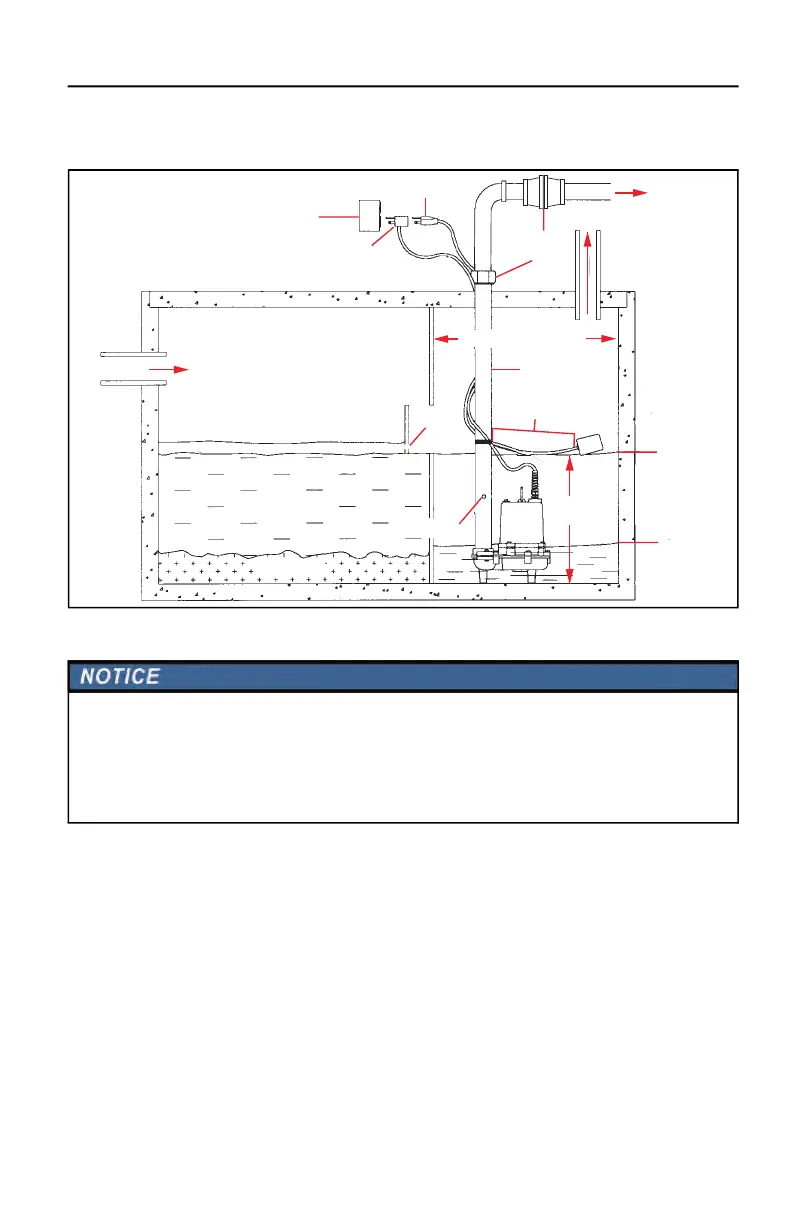

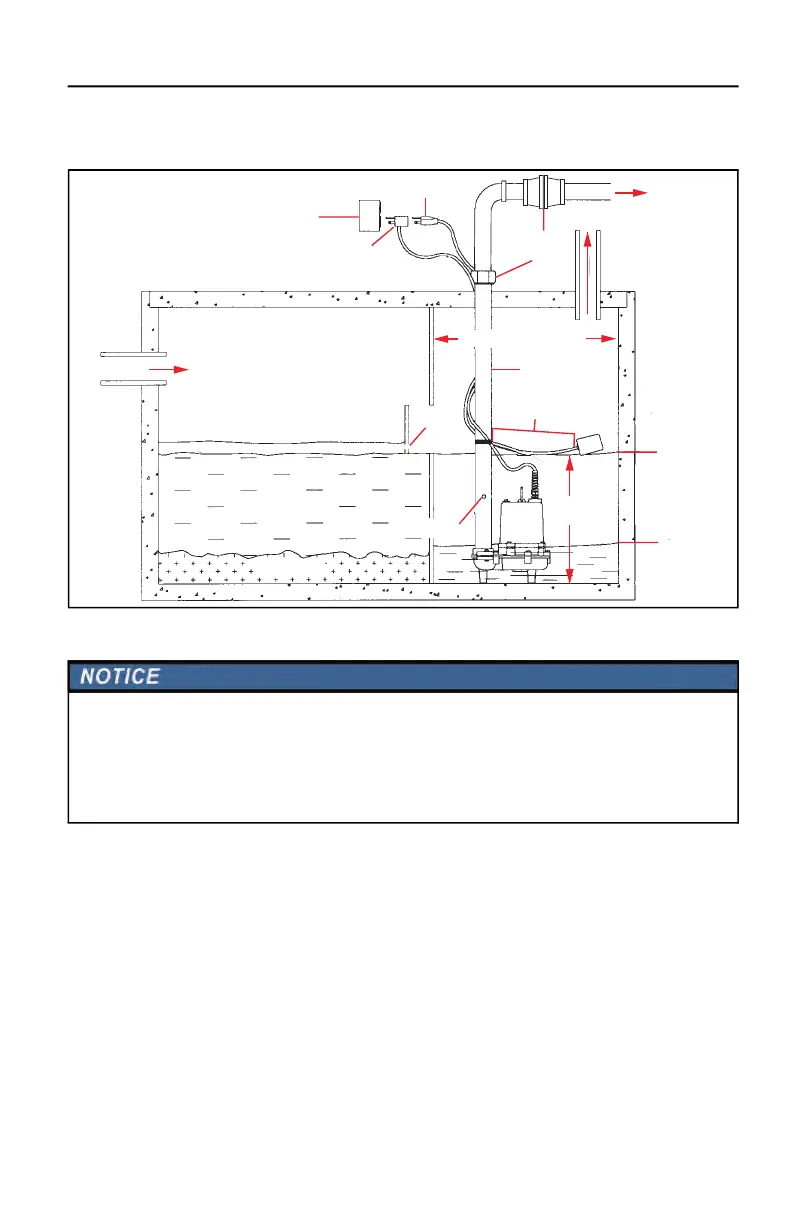

Scum

Septic Tank Chamber

In Flow

Bae

Tank Vent

Tank/basin

minimum size 1.5 ft (.5 m)

Union

DischargePump Power Cord

Check Valve

Float switch piggyback plug

(automatic models only)

Discharge Pipe

Outlet minimum

4 ft (1.2 m) above floor level

STOP

Minimum 4" (10.2 cm)

free length of cable

2 ft

(.6 m)

Air Relief Bleed Hole

Sediments

START

Risk of damage to pump or other equipment.

• Support pump and piping when assembling and when installed. Failure to do so may cause piping to break, pump

to fail, motor bearing failures, etc.

• Do not install the check valve in a vertical position, as solids may settle in the valve and prevent the valve from

opening on start-up. For best performance of the check valve when handling solids, install it in a horizontal posi-

tion or at an angle of no more than 45°.

Loading...

Loading...