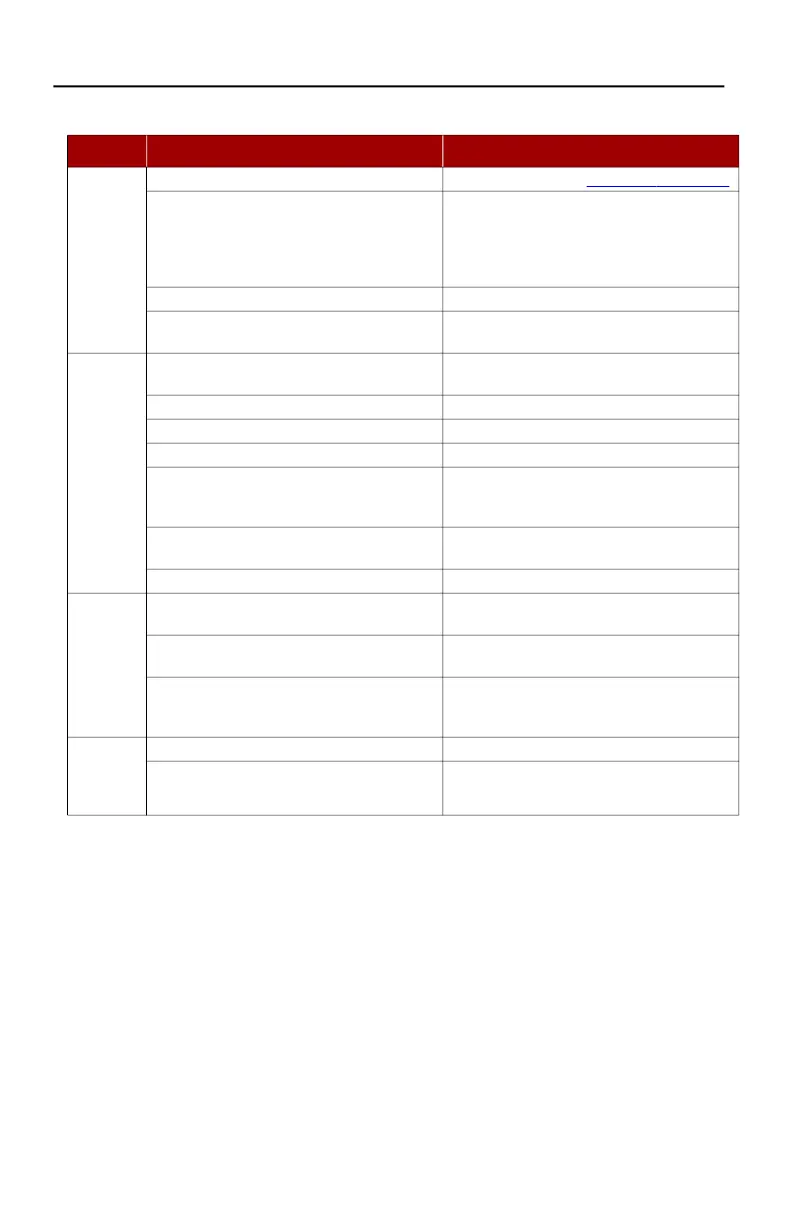

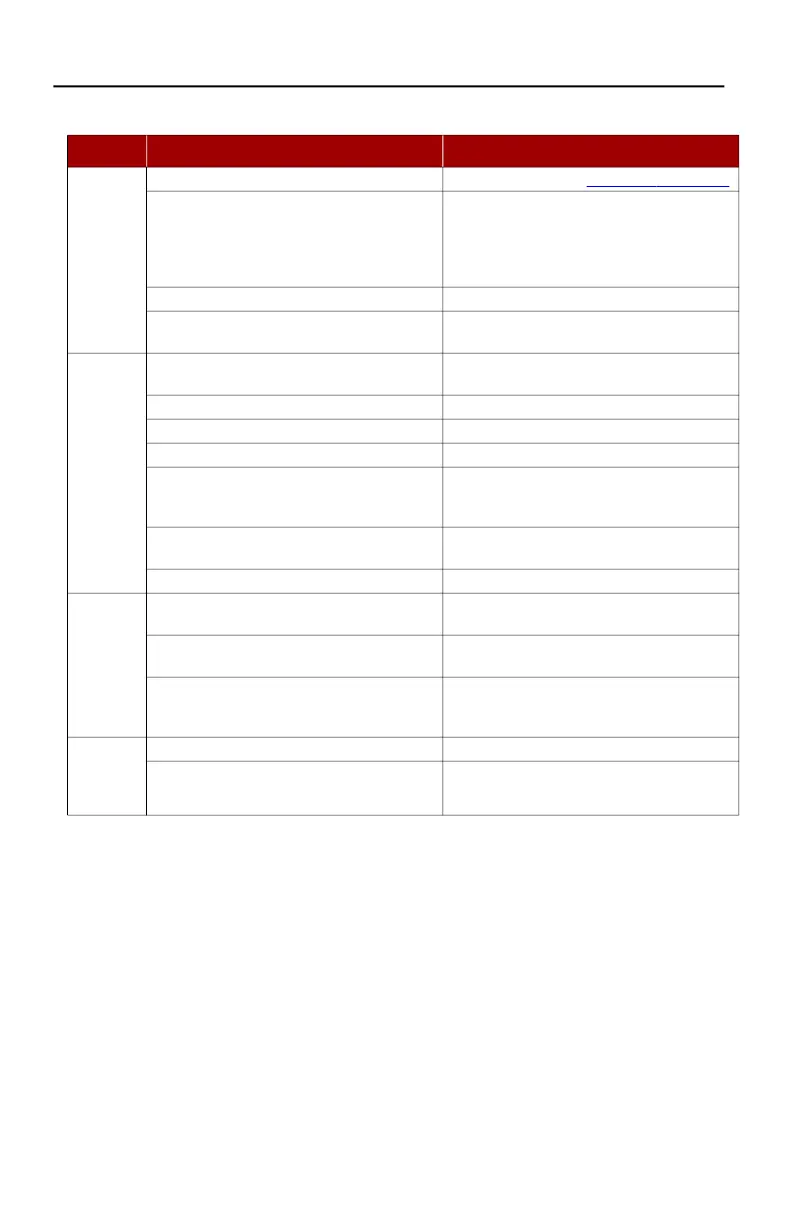

MAINTENANCE

Troubleshooting

8

Troubleshooting

Problem Probable Causes Corrective Action

Pump fails

to deliver

water

Pump not completely primed Prime pump. Refer to “

Operation” on page 6.

Speed too low

Employ a certified electrician to check volt-

age at motor terminals and at meter when

pump is operating. If low, refer to wiring

instructions or check with your power com-

pany. Check loose connections.

Total head exceeds pump rating Reduce total head or use a high head pump.

Suction lift is greater than recommended

Relocate the pump closer to the water

source.

Pump

delivers

water, but

not at

rated

capacity

Air pockets or leaks in suction or discharge

line.

Inspect the suction and discharge lines.

Clean or replace as needed.

Clogged impeller. Remove impeller and clean.

Excessively worn impeller. Replace impeller.

Strainer is too small or clogged. Use larger strainer or clean.

Insufficient submergence of suction line.

Adjust installation so that the end of the suc-

tion line remains well below the water sur-

face.

Suction lift is greater than recommended

Relocate the pump closer to the water

source.

Total head exceeds pump rating Reduce total head or use a high head pump.

Pump

loses

prime

Air leaks in suction line

Inspect suction line. Repair or replace as

needed.

Excessive lift and operating too near shut-off

point

Relocate the pump closer to the water

source.

Water level drops while pumping, uncover-

ing suction piping

Check water supply. Add length of pipe to

suction to keep submerged end under water,

or move the pump closer to source of liquid.

Mechani-

cal trou-

bles and

noise

Bent shaft and/or damaged bearings Take motor to authorized motor repair shop.

Suction and/or discharge piping not properly

supported and anchored

See that all piping is supported to relieve

strain on pump assembly.

Loading...

Loading...