18

3. Repeat this operation with the adjacent crank and continue this way till the crankshaft will operate

more smoothly.

@ After any repair on the crankshaft, the crankshaft nuts should be checked regularly, see 12.0

@ Don’t assemble the cranks at the wrong side of the machine. See the spare part for the right part

numbers

.

15.3 ALIGNMENT OF AN ELEMENT

In the event that an element is no longer in line with the adjacent elements, the alignment can be

corrected as follows (see fig.8.):

- Slacken the four bolts/nuts A, that connect the crankshaft to the element.

- Slacken the two bolts B, that fix the element to the main frame.

- Try to align the element by moving it side wards, till it ligns up with the adjacent ones.

- Start to tighten all bolts/nuts.

@ The element may be pushed out of line due to overload to the machine

@ When a crank is replaced, always realign the element, because if no additional tension is created

in the total element assembly.

@ Any pre-tension in the element assembly will shorten the bearing life and may damage other parts

as well.

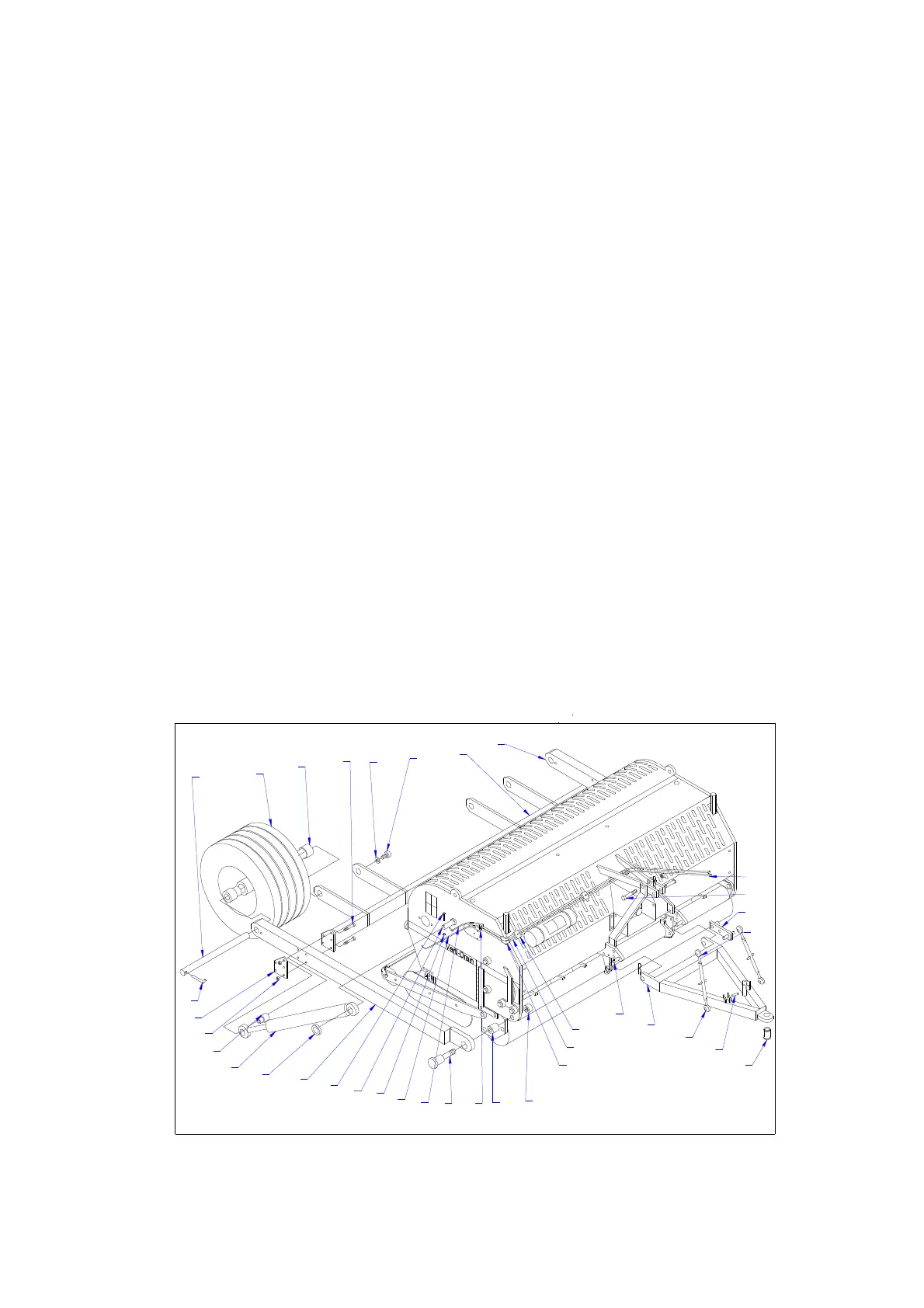

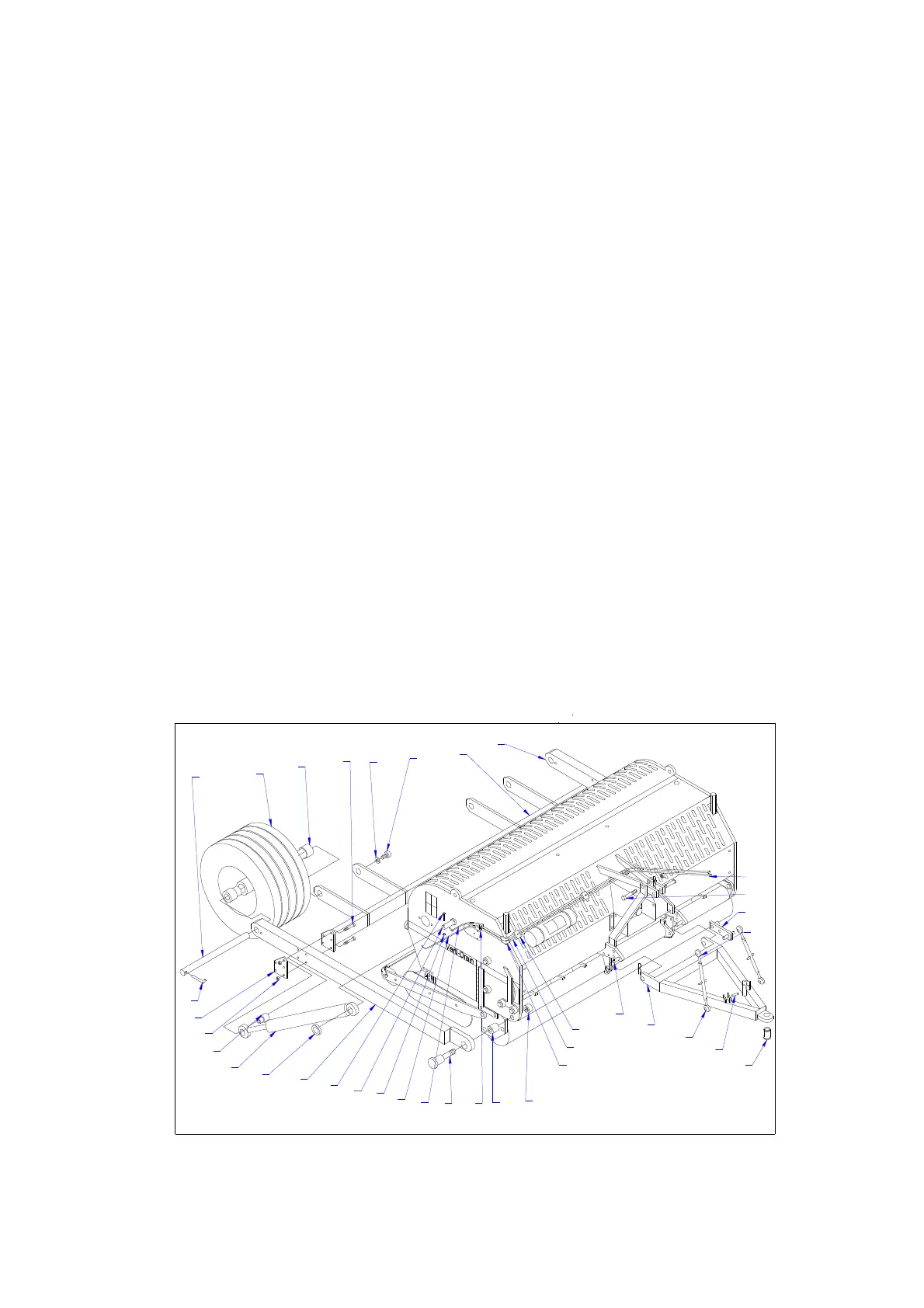

16.0 OPTIONS, WHEEL KIT

The partnumber for a full transport kit for the 7516 is 9500100. This kit will be separately delivered

and can be mounted to a standard 3-point linkage machine. Generally speaking, a machine with

wheel kit will reduce the minimum horsepower required by 10 HP It also can be taken off quickly, so

the machine can be used either way

#

*

+

,

-

)

.

/

0

1

&

2

3

4

5

6

7

3

(

8

#

"

9

"

9

8

(

+

Loading...

Loading...