18

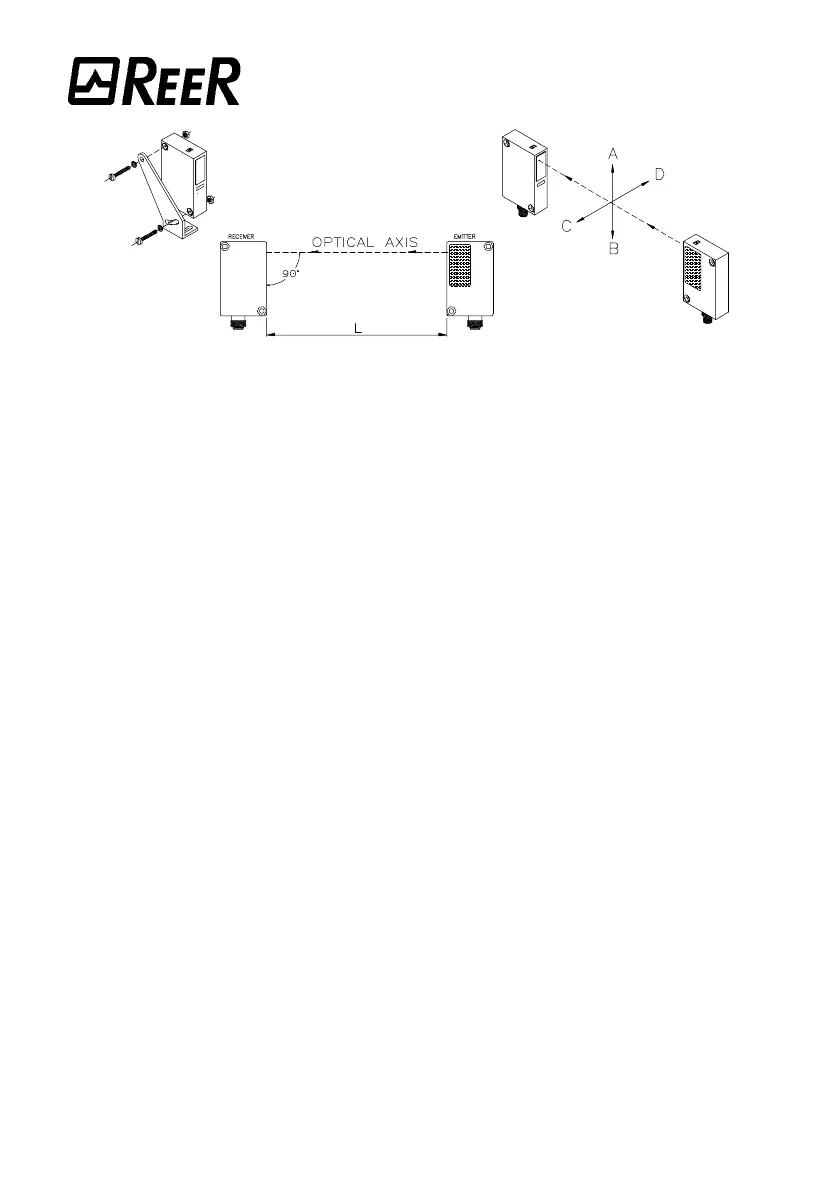

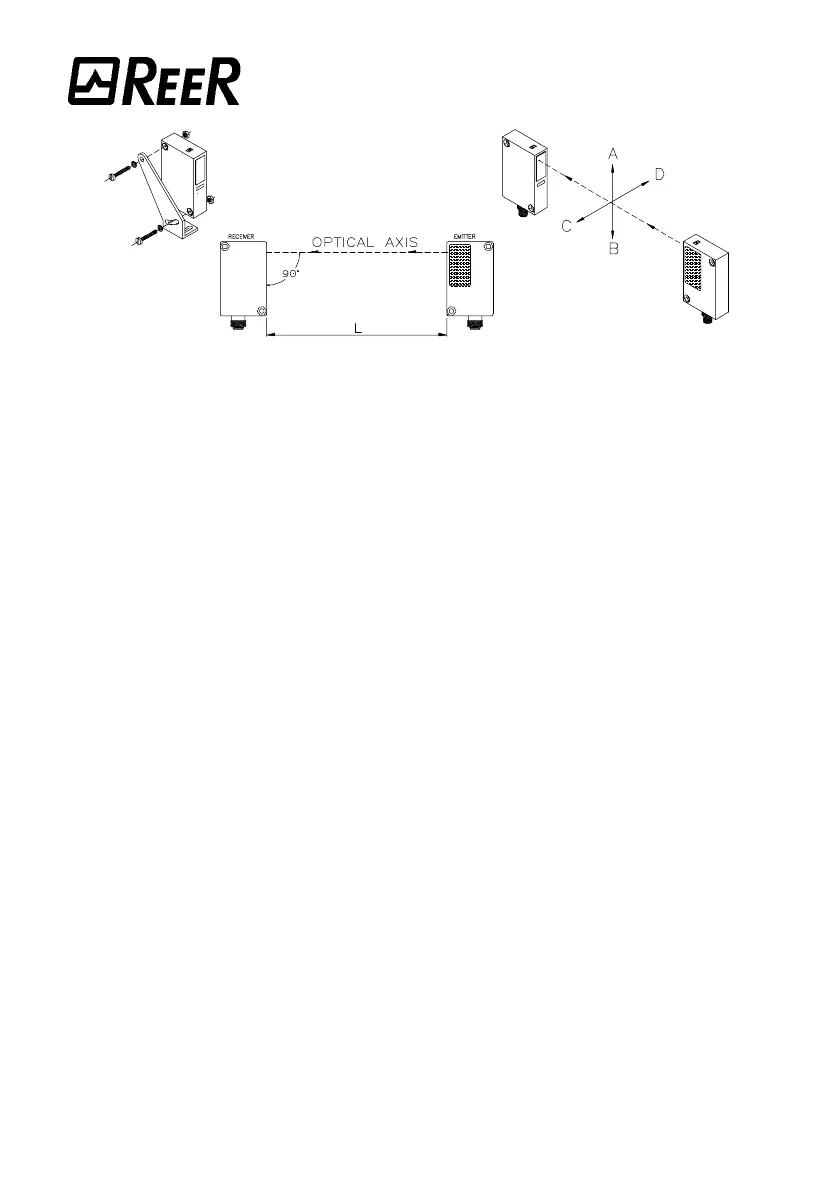

Figure 9

CHECKING and MAINTENANCE

The MINERVA photocell must be used within the operating temperature parameters

given in the technical data. Before each work shift or power-up, verify the correct

operation of the photocell through the following procedure:

intercept the beam by means of a non-transparent cylinder shaped object with 12 mm

diameter, to be placed first in the centre of the area between the emitter and the receiver,

and then close to both components. During each stage make sure that the area occupied

red led lights up, the free area green led goes out, and the control unit output is switched

accordingly.

The MINERVA photocell does not require any special maintenance. However, we

recommend cleaning the lenses of the emitter and the receiver at regular intervals, so as

to prevent dust from accumulating as this would undermine the optical beam

transmission and reception functions, and might result in failure of the equipment and

the machine linked up to it. At all events, do not use abrasive or corrosive products,

solvents or alcohol which might harm the surfaces to be cleaned.

FAULTS

In general, if any fault is observed and is seen to persist even after turning the equipment

on and off, first of all check the conditions of the electrical connections.

Furthermore, make sure that the emitter and the receiver are correctly aligned and the

lenses are perfectly clean. If the above checks are not sufficient to restore trouble-free

system operation, send the equipment to our laboratories, complete with all parts, stating

clearly:

• part number;

• date of installation;

• operating period;

• type of installation;

• fault observed.

Loading...

Loading...