6

4.2 PIPING

System piping must be done following industry standards

for good piping practices as well as comply with local codes.

Refer to page 18 for a typical eld piping diagram. After

piping is completed all joints and connections should be leak

tested.

Use top quality copper tubing that is internally free of dirt or

other contaminants.

Equivalent pressure drop from piping should be 15 psi or

lower.

Connect 7/8" OD inlet piping to city water or tank supply.

Connect 5/8" OD outlet piping to unit (7/8" OD for pumping

station with 8 GPM pump).

Connect both 5/8" OD drain outlets.

WATER IN (7/8” OD)

CITY WATER OR TANK

WATER OUT

(5/8” OD - 4 GPM)

(7/8” OD - 8 GPM)

DRAIN (5/8” OD)

DRAIN (5/8” OD)

Figure 2 Piping connections

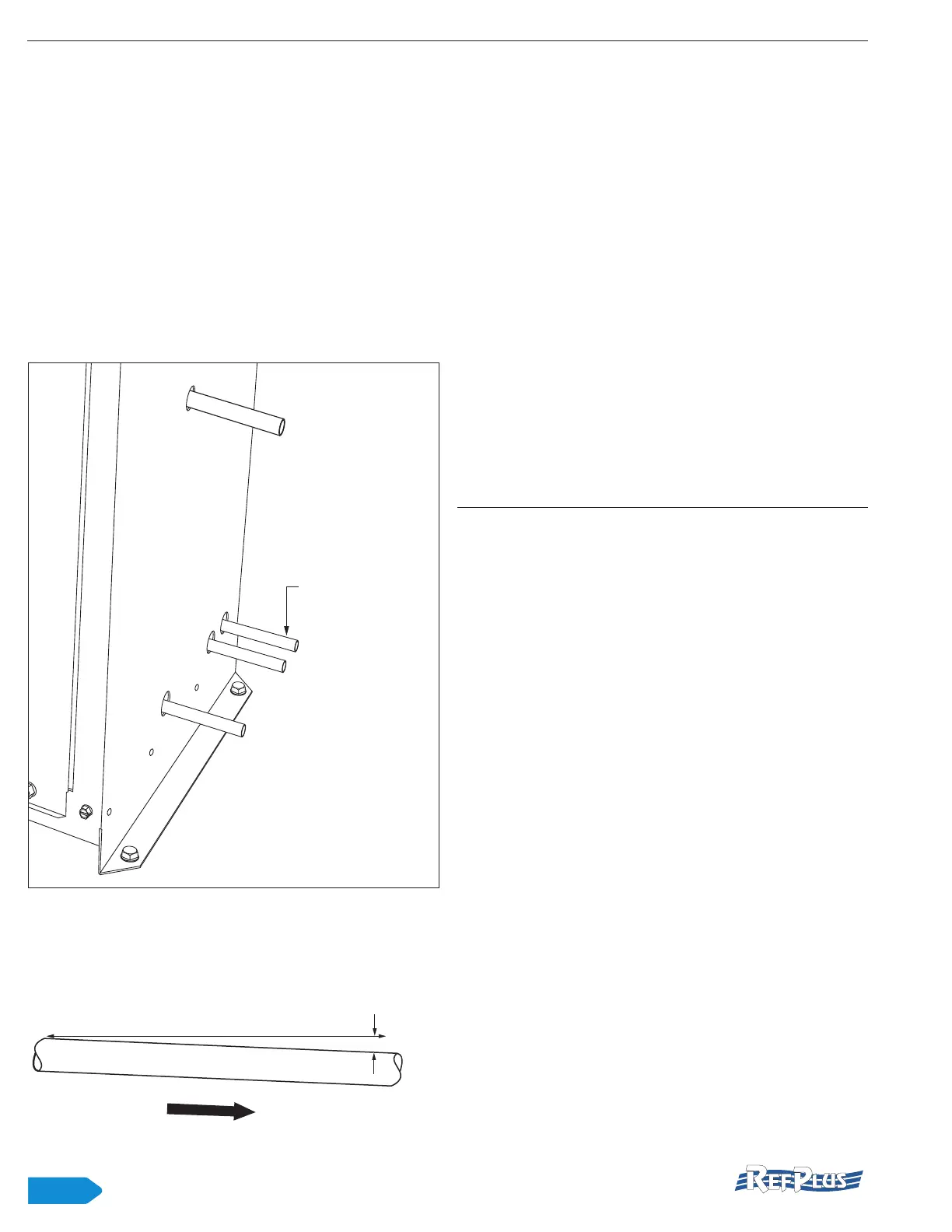

All piping should have a minimum slope of 1/4"/12" away

from the heat rejection unit (fluid/gas cooler or condenser).

12”

1/4”

AWAY FROM COOLING UNIT

Figure 3 Piping slope

4.3 WIRING

IMPORTANT: Wire connections may have come loose

during transit. Check all screws for tightness prior to

starting up the unit.

The pumping station must be grounded.

All system wiring must follow applicable local and

national codes.

Internal wiring of pumping station has been completed at

the factory. Wiring connection ends on terminal blocks in the

control panel and are clearly labeled. Check the nameplate

with the current characteristics to be used for wiring.

Connect the pumping station in accordance with supplied

wiring diagrams.

Systems are available for 120V/1PH/60Hz, 230V/1PH/60Hz

and 208V/3PH/60Hz. Other voltages may be available upon

special request.

IMPORTANT: For a 230V/1PH/60Hz system, 208V/1PH/60Hz

is not acceptable and must be avoided as this could damage

the pump.

5. START-UP

Before starting the adiabatic pre-cooling system for the rst

time, or after system was shut down a long period, always

carry out the following start-up procedure:

• Check water supply

• Check air vent (proper connection)

• Check proper interlock connection

• Check uid and outside temperature sensors (proper

connection)

• Check pulsing valve for proper operation

• Check water particle lter (properly in place)

• Check pump current (consumed)

• Check water pressures (see section 6 below).

• Check unit voltage and compare to wiring diagram

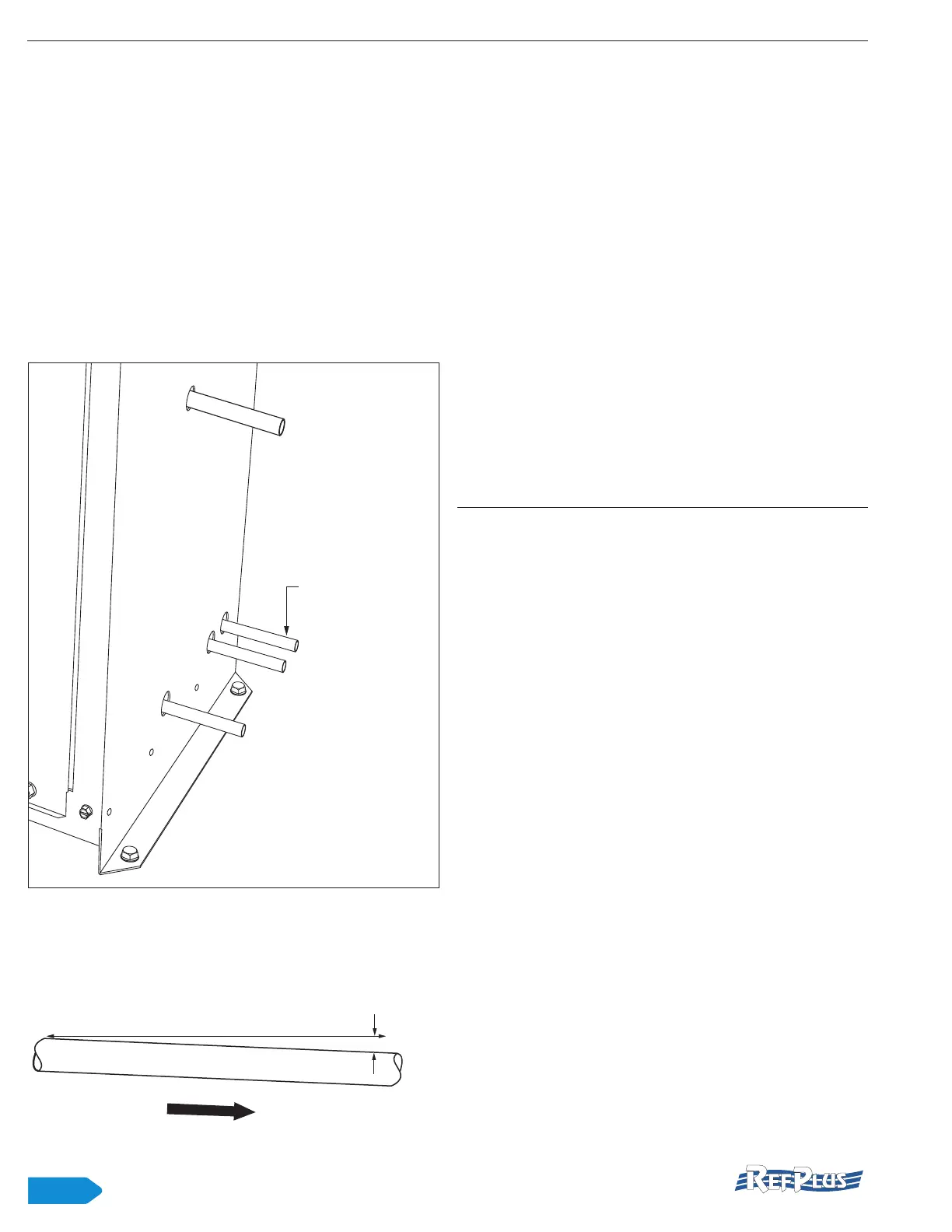

• Check atomizing nozzles for leaks (properly tightened).

Also, make sure nozzles are aiming away from the coil,

at 180

o

, as shown in gure 4. Pipes may have shifted

during transportation.

IMPORTANT: Each adiabatic pre-cooling system comes

with a start-up report form that must be completed during

installation and sent back to RefPlus. This is to insure

proper follow-up from the manufacturer and to activate

the warranty. This form is also available at the end of this

manual or online at refplus.com, under the Service tab.

INSTALLATION START-UP

Loading...

Loading...