9

R

TROUBLESHOOTING

9. TROUBLESHOOTING

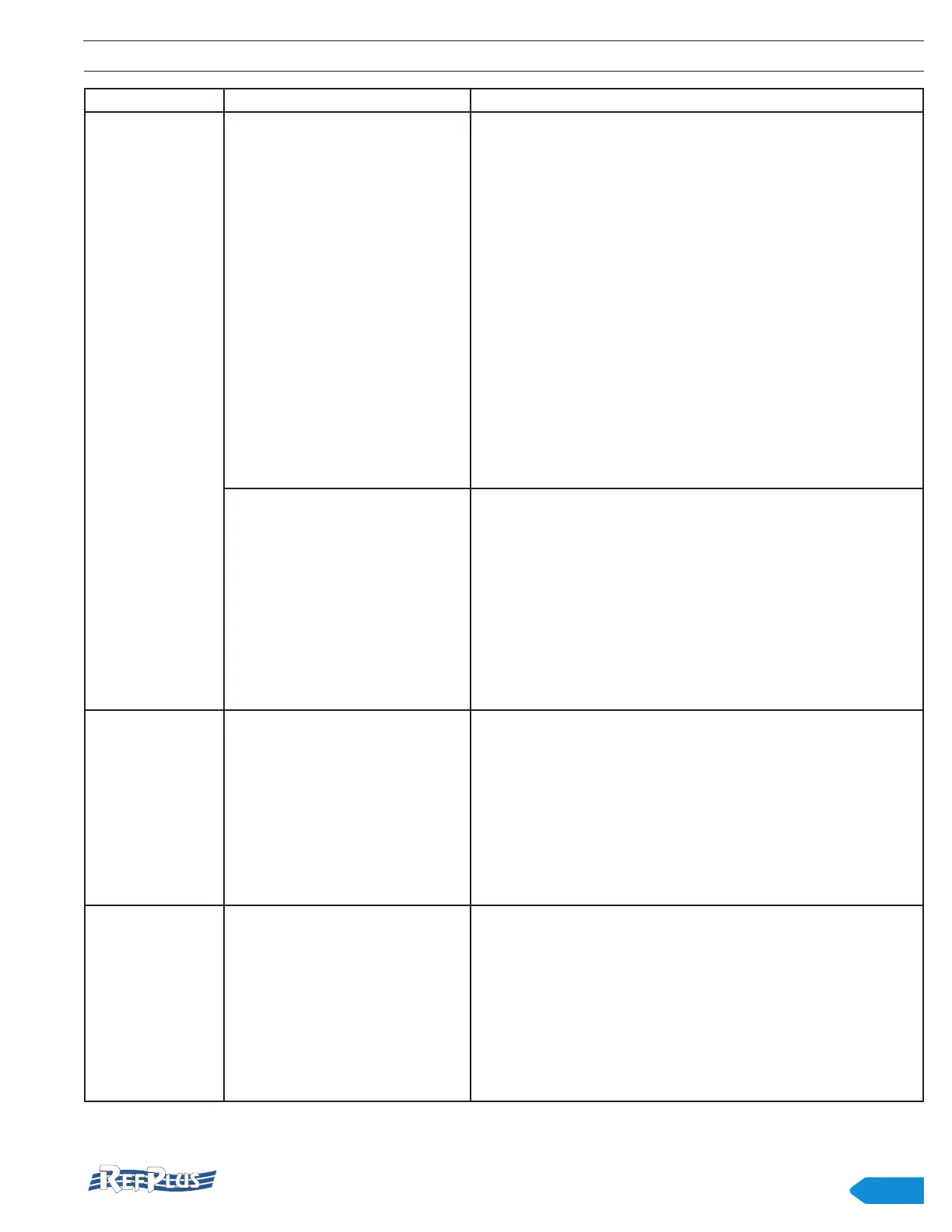

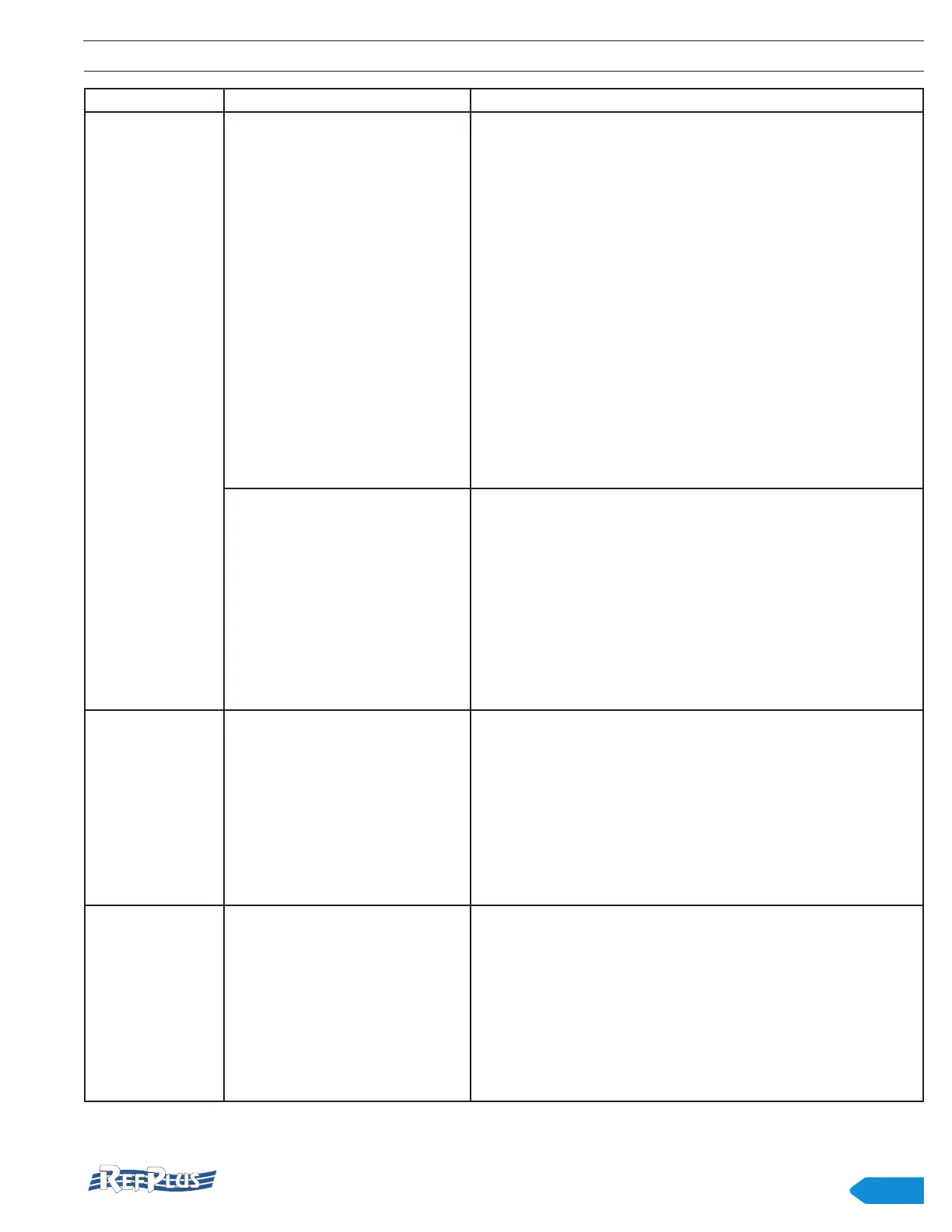

PROBLEM POSSIBLE CAUSES POSSIBLE CORRECTIVE STEPS

Fluid outlet

temperature

on cooler (gas

pressure on

condenser) stays

high, won't come

down.

The system does not spray water

and pump is not running.

1. Check if Status on Main Status screen is ON. If not, switch the

system ON and check for alarms and continue troubleshooting.

2. Check Offsets. They should be at zero during normal operation or

can be used to simulate FT and OT to create a Cooling demand.

Refer to page 28 of the adiabatic controller programming

manual.

3. Check that cooling demand (CD) on Main Status Screen is at

least 10%. Adjusted to 10% by default, refer to page 18 of the

Adiabatic Controller programming manual.

4. On Main Status screen, check if drain valve and water treatment

system are CLOSED and ON. If not, you may need to wait for OT

to increase above Drain temp + Drain temp Band (or for tests,

insert OT Offset to simulate the condition). Refer to page 27 for

Drain Temp. and page 28 for Offets and Drain temp. Band of the

adiabatic controller programming manual.

5. Check that no critical alarm is triggered, such as FT or OT sensor

failure, Water inlet LPS alarm or Water high pressure. Identify alarm,

x condition and reset alarm by following instructions on page 32 of

the adiabatic controller programming manual. Check that the cooler

(or condenser) switches the interlock to call for the system to run.

The system sprays water and pump

is running.

1. Check coils for blockage.

2. Check if cooler/condenser fans are all running at full speed.

3. Check if there is excessive water dropping from the spraying

system. If not, increase amount of water delivered to the nozzles.

Refer to the Operation Principle/Sequence of Operation section

of the adiabatic controller programming manual to understand

your conguration and adjust the amount of water by following

instructions on page 17 to page 19. The amount of water

should be enough to make the uid/gas temperature (FT) or

pressure decrease while avoiding too much water dropping from

the cooler/condenser coil.

On the main status

screen, uid tem-

perature reading

(FT) displays an

abnormal reading,

completely out of

range

Badly programmed offset or faulty

sensor.

1. Check FT offset, return offset to zero. Refer to page 28 of the

adiabatic controller programming manual to adjust offsets.

2. Check FT sensor wires, one should be on B2 (port J2) and the other

one on Ground (port J2); no other wire should be in contact with the

wire on B2 (port J2).

3. Check sensor and wiring. Look for open wire or short. Disconnect

wires from B2 and Ground (port J2), read resistance, should be

around 10 Kohms at 25

o

C, 27K ohms at 0

o

C. If reading open,

replace sensor.

On the main status

screen, the outside

temperature reading

(OT) displays an

abnormal reading,

completely out of

range.

Badly programmed offset or faulty

sensor.

1. Check OT offset, return offset to zero. Refer to page 28 of the

adiabatic controller programming manual to adjust offsets.

2. Check OT sensor wires, one should be on B1 (port J2) and the

other one on Ground (port J2); no other wire should be in

contact

with the wire on B1 (port J2).

3. Check sensor and wiring. Look for open wire or short. Disconnect

wires from B1 and Ground (port J2), read resistance, should be

around 10 Kohms at 25

o

C, 27K ohms at 0

o

C. If reading open,

replace sensor.

Loading...

Loading...