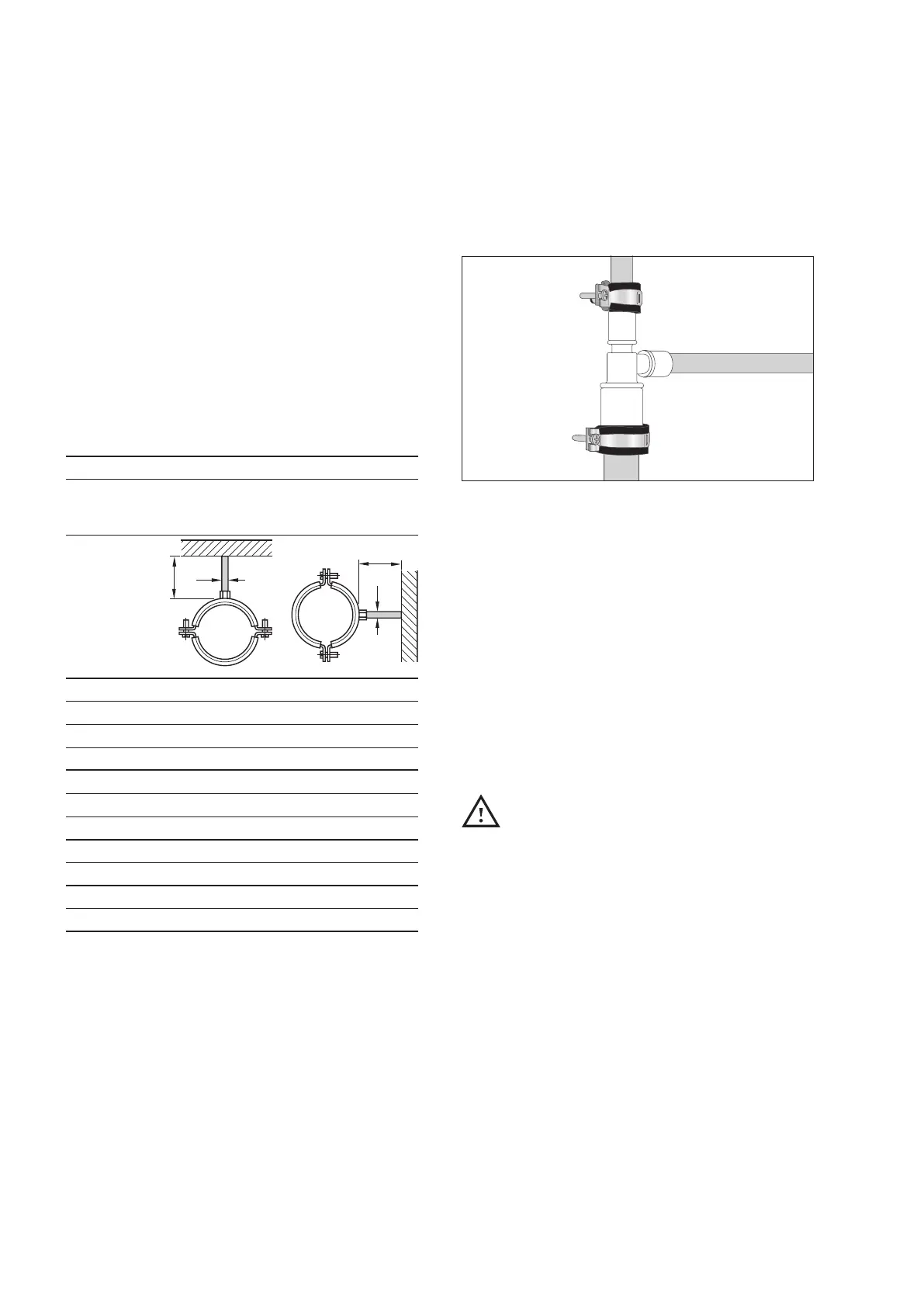

• Anchor points can be used to restrict the

thermal linear expansion into one direction.

• Long pipe runs can be divided into several sections

by adding several anchor points.

• Anchor points can be fixed at tees, elbows or

connectors. Anchor points can be fixed by installing

a pipe bracket directly before each compression

sleeve of the fitting.

• For installation without pipe support channel, install

anchor points at 6 m intervals. Please refer to section

6-6 for more information on pipe support channels.

Pipe brackets shall not be installed on

compression sleeves

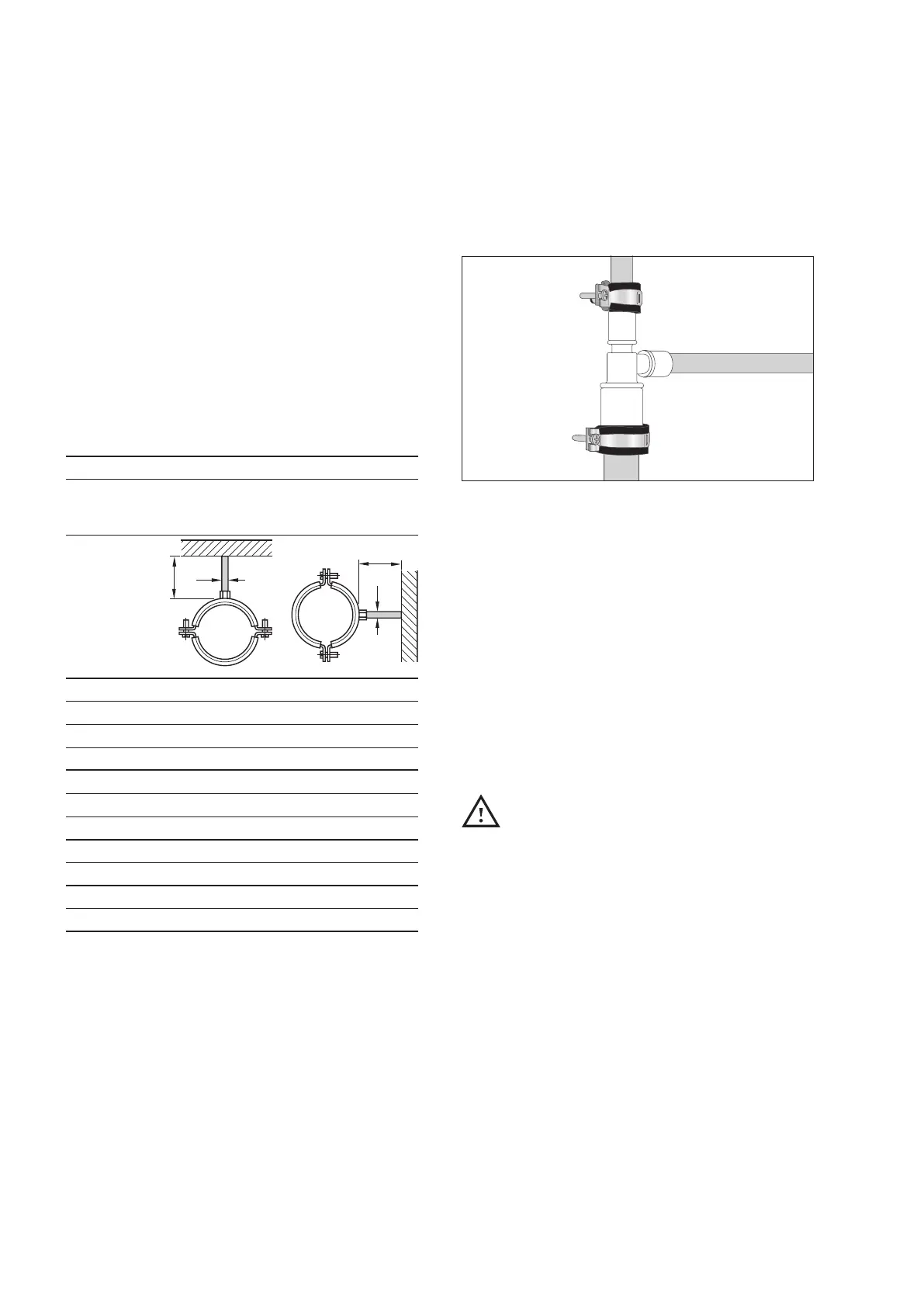

6.5.2 Anchor points

Fig. 6-3

Anchor point made by pipe clamps

B A

Pipe size

[mm]

Thread diameter or

pipe nipple diameter

Maximum distance

of wall/ceiling to the

pipe clamp [mm]

16 M8 100

M10 150

M12 200

M16 300

20 M10 100

M12 150

M16 250

25 M12 100

M16 200

32 M16 100

R ½ 150

B

B

Tab. 6-2

Guideline values for fixing parameters of anchor points

6.5

Pipe support and fixing

6.5.1

Pipe brackets and clips

Use only pipe brackets and clips with the following

properties:

• Suitable for plastic pipes

• Improved acoustic properties through rubber lining

• Correct size (to allow easy gliding of pipe without

pulling the rubber lining out)

• Free of burrs

6.5.3 Spacing between brackets and clips

Choose the correct pipe spacing intervals according to

the guideline values (see Table 6-2) for installation with or

without pipe support channels. AS NZS 3500 guidelines

for bracket and clip spacing are also approved for EDGE

TM

pipes.

Loading...

Loading...