Rekluse Core EXP - Hydraulic Page 13

CLUTCH NOISE

Although it is harmless, some bike models may

have “squeal” or “chatter” coming from the clutch at

low RPM as it engages. Clutch squeal is caused by

the clutch components vibrating as the clutch

engages and can become more audible as the

clutch gets hot. For bike models that tend to have

clutch squeal or chatter here are some

recommendations to reduce or eliminate it:

- Oil: For optimal clutch performance Rekluse

recommends using fresh, clean oil that meets

JASO-MA oil rating requirements. Rekluse

offers Factory Formulated Oil™ developed

specifically for Rekluse products. Rekluse

Factory Formulated Oil is a perfect complement

to any OEM or aftermarket wet clutch. Visit

www.rekluse.com to learn more.

- Clutch Basket: Available for some models, a

Rekluse Clutch Basket will eliminate clutch

squeal and chatter in most cases because it is

precision machined from high quality material

and includes long-life clutch dampers. A clutch

basket that is damaged or has worn-out

dampers tends to increase clutch noise.

- Installed Gap: Adjusting the Installed Gap will

NOT affect clutch squeal or chatter

MAINTENANCE

- Maintain adequate free play gain, checking

before every ride and adjusting if necessary.

- Keep up with regular oil changes as per the

bike manufacturer’s recommendations. Clutch

function and longevity depends on oil quality.

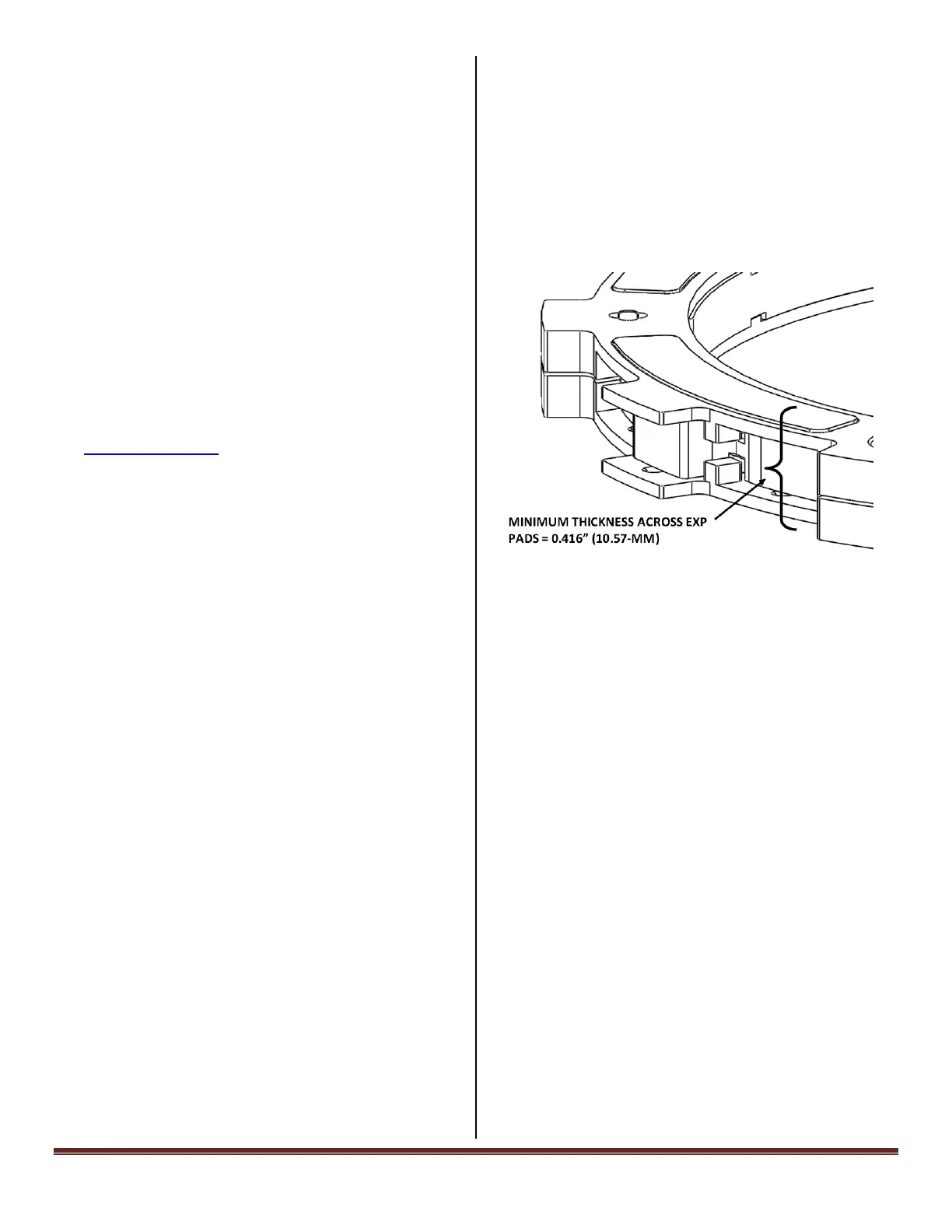

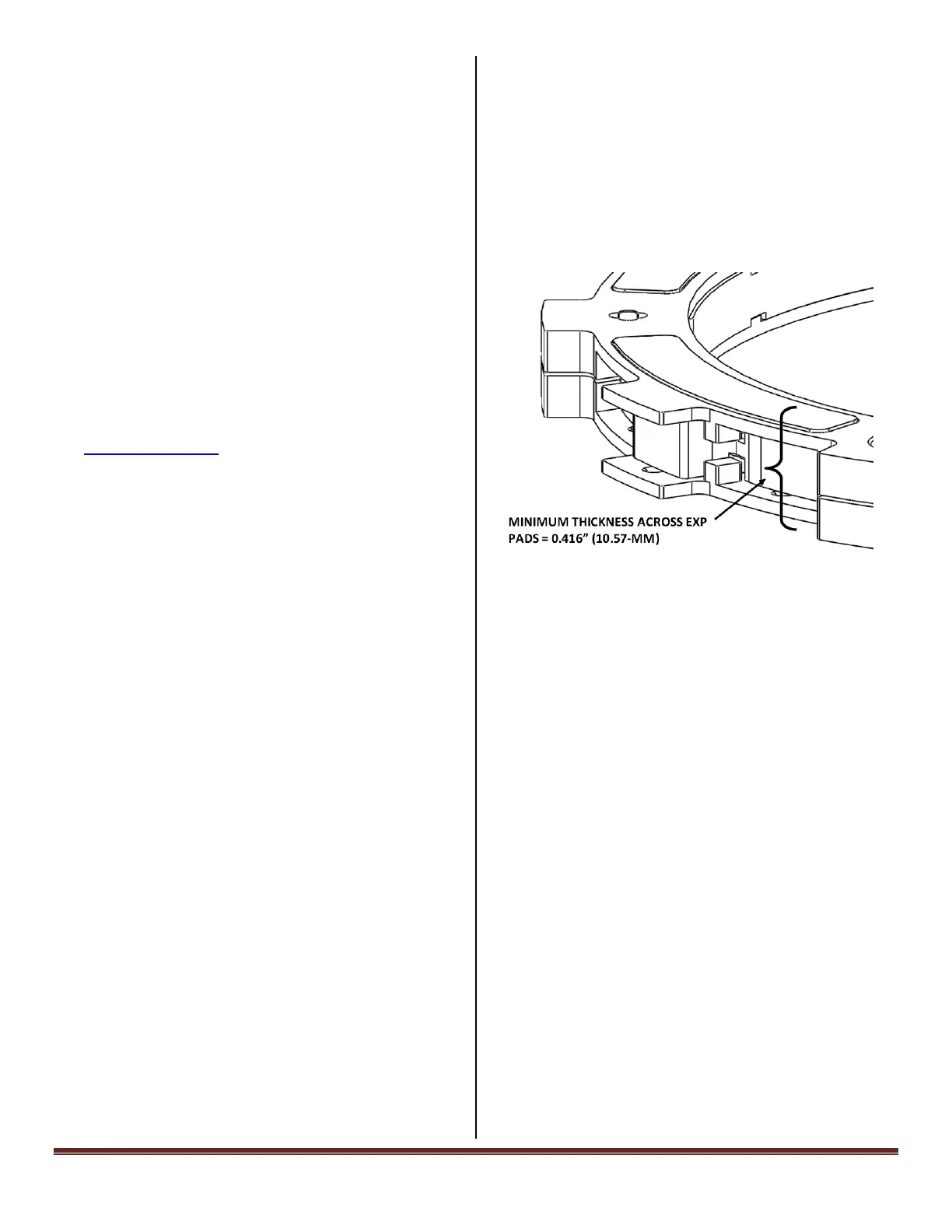

- Inspect all of your clutch parts every 40 hours

for signs of wear or excessive heat, and replace

components as necessary.

- Repeat the break-in procedure anytime the

friction disks or EXP bases or wedges are

replaced. Always soak friction disks or EXP

bases in oil for at least 5 minutes before

installing.

Loading...

Loading...